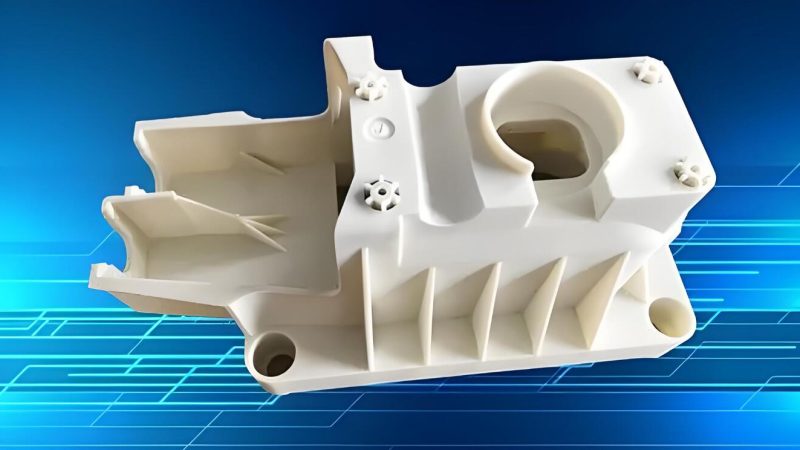

Transformez vos idées en produits de haute qualité

HOFeng peut mouler n'importe quel thermoplastique. Services de moulage par injection rentables pour vos produits et pièces sur mesure.

Plus de 15 ans d'expérience dans la fabrication de produits sur mesure selon les normes ISO

- Outil de prototypage en 10 jours

- Outil de production dans les 2 semaines

- ISO 9001:2015 - L'essentiel pour les inspections de qualité

- N'hésitez pas à nous contacter pour nous faire part de vos besoins spécifiques en matière de résine.

qu'est-ce que le moulage par injection ?

Le moulage par injection est une méthode de moulage qui combine l'injection et le moulage, également connu sous le nom de moulage par injection. La méthode générale de moulage par injection consiste à placer des granulés ou des poudres de composants polymères dans le cylindre d'une machine de moulage par injection, où ils sont soumis à des processus de chauffage, de compression, de cisaillement, de mélange et de transport. Ensuite, à l'aide d'un piston ou d'une vis, une pression est appliquée au polymère fondu. La matière fondue à haute température est ensuite injectée dans une cavité de moule à basse température pré-fermée, par l'intermédiaire de la buse située à l'avant du cylindre et du système d'obturation du moule. Après refroidissement et solidification, le moule peut être ouvert, le produit peut être éjecté et des produits en plastique présentant certaines formes géométriques et une certaine précision peuvent être obtenus.Le moulage par injection est utilisé pour créer de nombreux objets tels que des boîtiers électroniques, des conteneurs, des bouchons de bouteille, des intérieurs automobiles, des peignes et la plupart des autres produits en plastique disponibles aujourd'hui.

Applications de moulage par injection

Les pièces injectées en plastique ont un rendement élevé et une large application. En effet, les pièces en plastique ont une certaine valeur pratique par rapport aux pièces en métal. Les plastiques sont largement utilisés comme composants structurels d'ingénierie, tels que les boîtiers, les cadres et les bases pour les instruments électroniques, l'automobile, les appareils ménagers et les équipements de communication, afin de protéger, d'améliorer et de construire une vaste gamme de produits. Le processus est connu pour ses capacités de rapidité, de précision et d'efficacité et est devenu l'un des services de fabrication les plus populaires pour la production de pièces en plastique.

Options de post-traitement et de finition

Le traitement de surface dans le moulage par injection désigne le processus d'application d'un traitement ou d'un revêtement spécifique à la surface d'une pièce usinée, comme la peinture ou les inserts remplaçables à chaud.

Inserts.Tampographie.Peinture.Sérigraphie.Soudure ultrason.Gravure laser.Revêtement UV.Piquetage.Marquage à chaud.Usinage post-moulage

Capacités de moulage par injection de plastique

Notre machine de moulage par injection:

Machine de moulage par injection à grande vitesse

Machine de moulage par injection de PVC spécial

Machine de moulage par injection spéciale PET

Machine de moulage par injection bicolore

Nous sommes capables de préserver une tolérance d'usinage de +/- 0,003 pouce (0,08 mm), tout en incorporant une tolérance de résine qui se situe dans une fourchette supérieure, mais jamais inférieure, à +/- 0,002 pouce par pouce (0,002 mm par mm).

Pour résoudre ce problème, nous utilisons des techniques d'usinage avancées et des équipements de précision afin de nous assurer que nos tolérances sont respectées avec la plus grande exactitude. La tolérance d'usinage de +/- 0,003 pouce (0,08 mm) garantit que le produit fini répond aux spécifications requises, tandis que la tolérance de résine incluse de +/- 0,002 pouce par pouce (0,002 mm par mm) permet un certain degré de flexibilité dans le matériau lui-même.

En maintenant ces tolérances serrées, nous sommes en mesure de fournir des produits de haute qualité qui répondent aux exigences de nos clients. Qu'il s'agisse d'applications industrielles ou de fabrication de précision, nous nous efforçons de dépasser les attentes et d'obtenir des résultats exceptionnels.

Matériaux de moulage par injection de plastique

Propriété :

Résistant aux chocs

Résistant à l'usure

Stabilité dimensionnelle

Résistance chimique

Caoutchouc comme

Coût-efficacité

Cosmétique

Matériaux :

ABS, PMMA, PVC, PE, PC

POM, PEEK, UHMW

ABDOMINAUX, PBT, HANCHES, PPS

PEEK, PP, PBT, PE, LDPE, PA

TPU, TPE, Silicone

PP, HDPE, LDPE

ABS, PC, HIPS

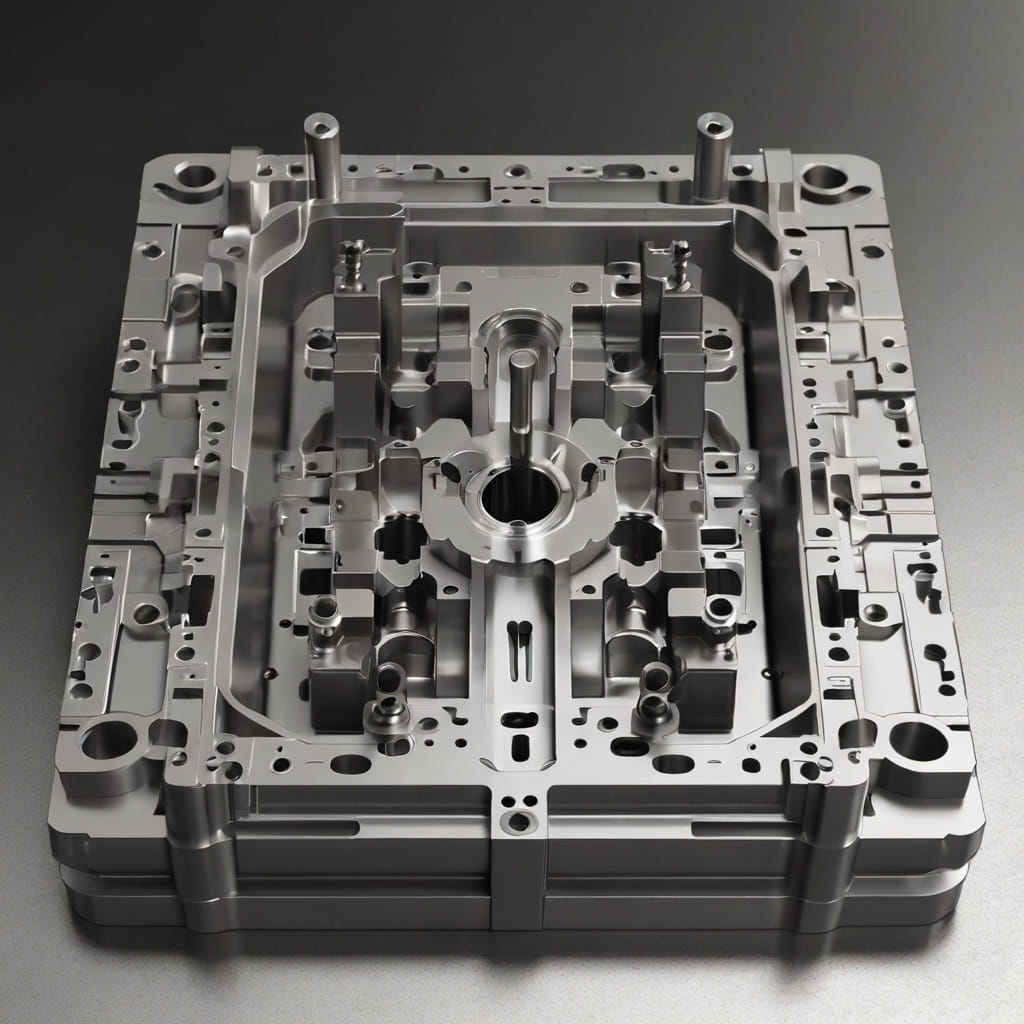

Dimensions maximales:

Taille:480mm x 751mm

Volume:966.837 cu.mm

Profondeur:101mm à partir du plan de joint

Surface de moulage prévue:112 903 mm².

Nos autres capacités de fabrication

Nous sommes spécialisés dans l'impression 3D, l'usinage CNC, le moulage sous vide, le moulage par injection et la fabrication de tôles, et proposons une grande variété de matériaux et de finitions de surface.

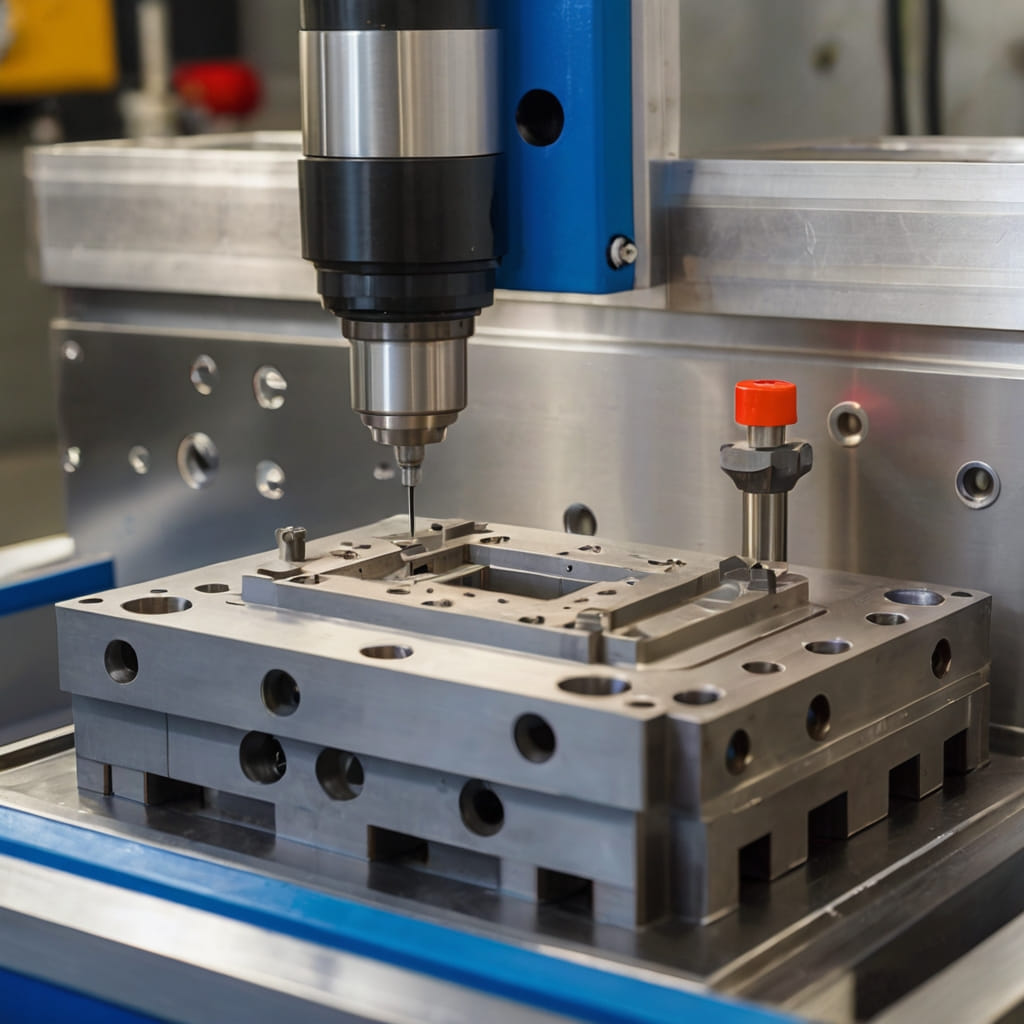

Usinage CNC

Nous disposons d'un centre d'usinage composite Mill-turn, d'une fraiseuse standard à 3 axes, d'une fraiseuse continue à 5 axes, d'une fraiseuse à 3+2 axes, d'un système de perçage et de post-traitement utilisant plus de 50 métaux et plastiques différents, disponibles dans plus de 15 finitions de surface. Tolérances jusqu'à ± 0,001 mm (0,0000394").

Services de moulage par injection

HOFeng peut mouler n'importe quel thermoplastique. Des services de moulage par injection rentables pour vos produits et pièces sur mesure. Outil prototype en moins de 10 jours Outil de production en moins de 2 semaines, ISO 9001:2015 | Critique pour les inspections de qualité

Service d'impression 3D

Le service d'impression 3D de HOFeng est votre centre de production de fabrication additive pour plus de 30 matériaux pour toutes les applications, service d'impression 3D. Nous sommes des experts en impression 3D pour répondre à toutes vos exigences de qualité industrielle.

Services de coulée d'uréthane

Nous fabriquons des prototypes et des pièces rapidement, dans un délai de 10 jours, avec une inspection 100% pour chaque pièce. Notre certification ISO 9001 nous permet d'offrir une qualité de haut niveau pour chaque lot.

FAQ sur le moulage par injection

Si vous avez un projet de moulage par injection prêt à démarrer, nous sommes là pour vous aider du début à la fin. Grâce à notre vaste gamme de services optionnels de post-traitement et aux mesures rigoureuses d'assurance qualité mises en œuvre par notre service dédié au contrôle qualité, vous pouvez être assuré de recevoir des produits qui répondent à vos attentes.

Il vous suffit de nous envoyer vos fichiers CAO en 3D et notre équipe vous fournira un devis gratuit. Nos ingénieurs modèles expérimentés effectueront une analyse approfondie de la conception en vue de la fabrication (DFM) de votre conception, afin de s'assurer que le produit final répond non seulement à vos normes de qualité, mais qu'il respecte également vos contraintes budgétaires.

Dans quel délai puis-je obtenir mes pièces ?

Les pièces de qualité de moins de 800 pièces peuvent être fabriquées en une semaine seulement si vous fournissez des modèles CAO 2D et 3D complets. Les pièces plus complexes nécessitant d'autres caractéristiques spéciales prendront plus de temps.

Quelles sont les considérations à prendre en compte lors de la conception de pièces destinées à l'usinage CNC ?

Les concepteurs doivent tenir compte de facteurs tels que l'accès aux outils, la sélection des matériaux, les tolérances et les finitions de surface lorsqu'ils conçoivent des pièces pour l'usinage CNC.

Quelle est la durée habituelle d'un processus d'usinage CNC ?

La durée d'un processus d'usinage CNC dépend de facteurs tels que la complexité de la pièce, le matériau utilisé et les tolérances souhaitées. Elle peut varier de quelques minutes à plusieurs heures.

Quelles sont les certifications ou les normes industrielles auxquelles vous adhérez dans vos processus d'usinage CNC ?

HOFeng est certifié ISO 9001 et conforme à la norme ISO 13485.

Quelles tolérances vos machines CNC peuvent-elles atteindre ?

Nos machines sont capables de tolérances aussi serrées que +/- 0.0002 pouces.

Combien coûte le moulage par injection?

Le calcul des coûts de moulage par injection fait intervenir de multiples facteurs, notamment la conception du produit, le coût des matières premières, le coût de la main-d'œuvre, la dépréciation de l'équipement, etc.

Conception du produit : La complexité, la taille, la forme et d'autres facteurs influencent le coût du moulage par injection. Certains produits complexes peuvent nécessiter des moules et des techniques de traitement spéciaux, et le coût augmentera en conséquence.

Coût des matières premières : Les différents types de matières premières plastiques ont des prix différents et sont également influencés par des facteurs tels que l'offre et la demande sur le marché. Les matières premières représentent une part considérable des coûts du moulage par injection.

Coût du moule : le moulage par injection nécessite l'utilisation de moules spécialement adaptés. Les coûts de conception, de fabrication et d'entretien du moule ont une incidence sur le coût.

Coût de la main-d'œuvre : Le fonctionnement de la machine de moulage par injection et le traitement ultérieur nécessitent une participation manuelle. Le coût de la main-d'œuvre est un élément du coût du moulage par injection qui ne peut être ignoré.

Consommation d'énergie : Les machines de moulage par injection consomment une grande quantité d'énergie telle que l'électricité et l'air comprimé. Les coûts énergétiques représentent également une part importante des coûts du moulage par injection.