Solutions pour l'industrie du pétrole et du gaz

- Parfaitement adaptés aux vannes de précision, aux bagues et aux capteurs, ils améliorent l'efficacité des infrastructures énergétiques.

Soutenir les services de fabrication de composants de précision pour l'énergie

HOFeng possède plusieurs années d'expérience dans la fabrication et le traitement de pièces de précision. Avec une conception industrielle et des processus de traitement matures, ainsi que diverses machines-outils et équipements à commande numérique, elle peut fabriquer des pièces de précision en combinaison.

Les équipements énergétiques reposent sur des accessoires de haute précision

Les industries du gaz naturel, du pétrole et de l'énergie s'appuient sur de nombreuses pièces usinées CNC. Les vannes de précision, les bagues et les équipements de détection nécessitent tous des pièces usinées de précision. Afin de maintenir le fonctionnement efficace d'importantes infrastructures énergétiques, les composants doivent être parfaitement coordonnés. Les pièces utilisées dans des environnements difficiles nécessitent une grande précision, ainsi qu'une résistance élevée à la corrosion et à la chaleur, et ces métaux requièrent généralement des outils de découpe CNC modernes.

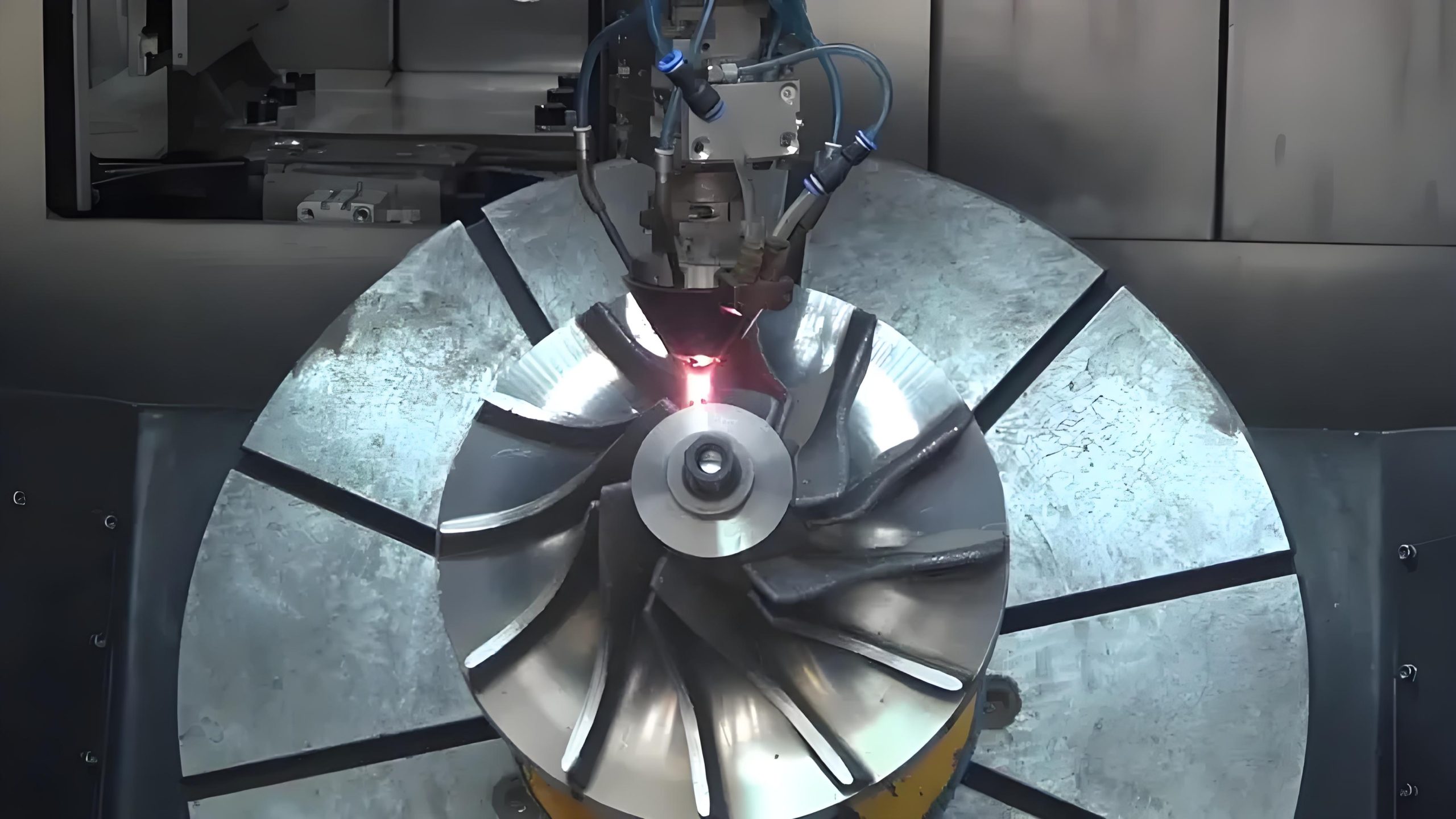

Technologie de fabrication hybride

Dans le domaine de la fabrication de pièces de précision, HOFeng a maîtrisé la technologie de fabrication hybride et est en mesure de produire des composants plus précis et de meilleure qualité à moindre coût et plus rapidement. Elle possède de grands avantages dans la fabrication de diverses pièces de précision et dans la combinaison d'équipements de soutien.

Les avantages de la technologie de fabrication hybride

Outre la possibilité de produire plus rapidement des pièces plus précises et de meilleure qualité, la technologie de fabrication hybride présente également plusieurs avantages

- Améliorer la productivité et accélérer la vitesse de production

- Obtenir une plus grande précision et des tolérances plus strictes

- Améliorer les performances mécaniques et réduire les coûts

- Réduire les investissements initiaux et les coûts d'exploitation

- Réduire considérablement le temps de fabrication

Inconvénients de la technologie de fabrication hybride

- Investissement initial élevé dans l'équipement pour la fabrication hybride

- La fabrication mixte nécessite un nombre élevé d'opérateurs

HOFeng aide les entreprises qui ont besoin de fabriquer des pièces de précision en leur fournissant des services intégrés, de la conception aux produits finis, grâce à des équipements existants et à des opérateurs qualifiés.

Fabrication de pièces de précision pour les équipements énergétiques

Nos autres capacités de fabrication

Nous sommes spécialisés dans l'impression 3D, l'usinage CNC, le moulage sous vide, le moulage par injection et la fabrication de tôles, et proposons une grande variété de matériaux et de finitions de surface.

Usinage CNC

Nous disposons d'un centre d'usinage composite Mill-turn, d'une fraiseuse standard à 3 axes, d'une fraiseuse continue à 5 axes, d'une fraiseuse à 3+2 axes, d'un système de perçage et de post-traitement utilisant plus de 50 métaux et plastiques différents, disponibles dans plus de 15 finitions de surface. Tolérances jusqu'à ± 0,001 mm (0,0000394").

Services de moulage par injection

HOFeng peut mouler n'importe quel thermoplastique. Des services de moulage par injection rentables pour vos produits et pièces sur mesure. Outil prototype en moins de 10 jours Outil de production en moins de 2 semaines, ISO 9001:2015 | Critique pour les inspections de qualité

Service d'impression 3D

Le service d'impression 3D de HOFeng est votre centre de production de fabrication additive pour plus de 30 matériaux pour toutes les applications, service d'impression 3D. Nous sommes des experts en impression 3D pour répondre à toutes vos exigences de qualité industrielle.

Services de coulée d'uréthane

Nous fabriquons des prototypes et des pièces rapidement, dans un délai de 10 jours, avec une inspection 100% pour chaque pièce. Notre certification ISO 9001 nous permet d'offrir une qualité de haut niveau pour chaque lot.