Fabrication et solutions pour les véhicules électriques

- Diverses pièces utilisées dans les automobiles, y compris des pièces extérieures et des solutions d'engrenage personnalisées

Services de traitement des pièces de véhicules électriques et de fabrication d'engrenages

HOFeng est profondément impliquée dans le domaine des pièces automobiles depuis de nombreuses années et dispose de capacités complètes en matière de conception, de traitement et d'assemblage. Elle est en mesure de fournir des services "tout-en-un" et d'apporter les meilleures solutions aux entreprises de fabrication de véhicules électriques.

Traitement personnalisé des pièces de véhicules électriques

HOFeng dispose d'un processus industriel complet de traitement personnalisé des pièces automobiles. Qu'il s'agisse de voitures traditionnelles ou de voitures électriques, la personnalisation et le traitement des pièces automobiles sont très avancés et permettent de répondre aux différents besoins des clients.

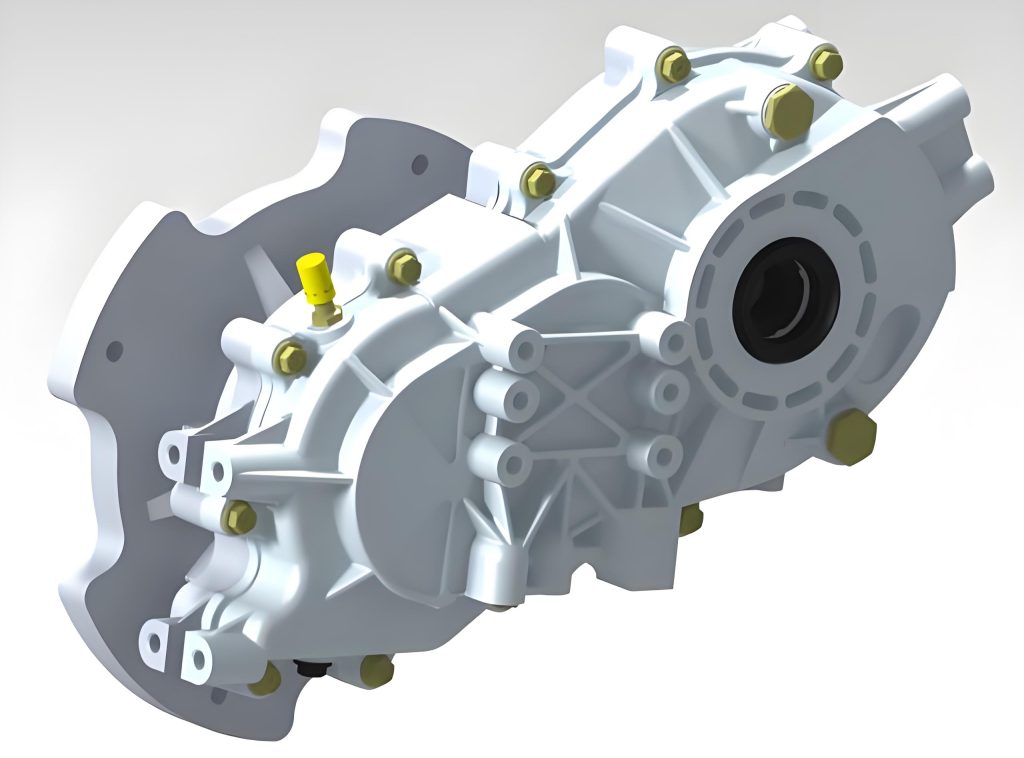

Personnalisation et usinage des engrenages de boîtes de vitesses

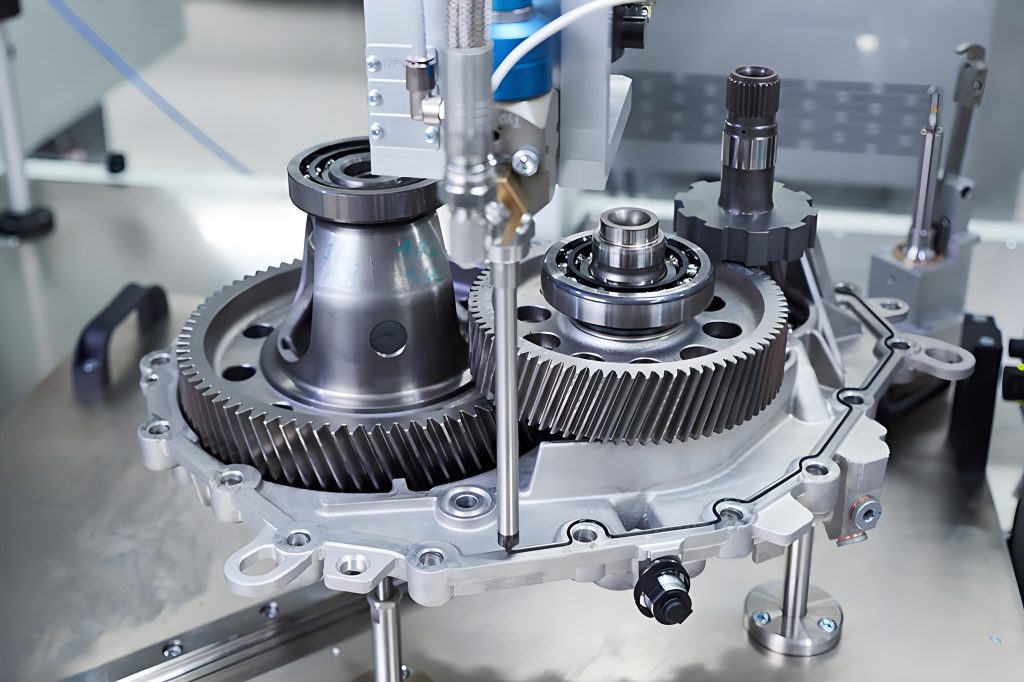

Les véhicules électriques ont des exigences plus élevées en ce qui concerne les engrenages de leurs transmissions. Par rapport aux transmissions des véhicules à essence, les transmissions planétaires sont plus petites et plus légères et, par conséquent, elles ont également des exigences plus élevées en matière de traitement des engrenages.

HOFeng s'appuie sur un système complet de fabrication industrielle à commande numérique pour traiter les différents engrenages.

Les avantages des engrenages personnalisés pour les transmissions de véhicules électriques

- Peut réduire le bruit du moteur ;

- L'embrayage peut amortir le couple ;

- Il permet d'étendre la plage de rendement élevé du moteur ;

- Rendre l'ensemble du véhicule plus puissant ;

- Il permet de réduire les besoins du moteur

Capacité de conception et de développement

NOTRE SERVICE

Nos autres capacités de fabrication

Nous sommes spécialisés dans l'impression 3D, l'usinage CNC, le moulage sous vide, le moulage par injection et la fabrication de tôles, et proposons une grande variété de matériaux et de finitions de surface.

Usinage CNC

Nous disposons d'un centre d'usinage composite Mill-turn, d'une fraiseuse standard à 3 axes, d'une fraiseuse continue à 5 axes, d'une fraiseuse à 3+2 axes, d'un système de perçage et de post-traitement utilisant plus de 50 métaux et plastiques différents, disponibles dans plus de 15 finitions de surface. Tolérances jusqu'à ± 0,001 mm (0,0000394").

Services de moulage par injection

HOFeng peut mouler n'importe quel thermoplastique. Des services de moulage par injection rentables pour vos produits et pièces sur mesure. Outil prototype en moins de 10 jours Outil de production en moins de 2 semaines, ISO 9001:2015 | Critique pour les inspections de qualité

Service d'impression 3D

Le service d'impression 3D de HOFeng est votre centre de production de fabrication additive pour plus de 30 matériaux pour toutes les applications, service d'impression 3D. Nous sommes des experts en impression 3D pour répondre à toutes vos exigences de qualité industrielle.

Services de coulée d'uréthane

Nous fabriquons des prototypes et des pièces rapidement, dans un délai de 10 jours, avec une inspection 100% pour chaque pièce. Notre certification ISO 9001 nous permet d'offrir une qualité de haut niveau pour chaque lot.