услуги по литью уретана

Наша компания, сертифицированная по стандарту ISO 9001, обеспечивает высокое качество каждой партии.

Мы являемся экспертами по полиуретановым материалам при разработке вашей продукции

- Запчасти в течение 10 дней

- 100% проверка каждой детали

- Изготовление для быстрого прототипирования и производства деталей

Все загружаемые материалы безопасны и конфиденциальны.

Процесс литья уретана

Мы можем предоставить вам информацию об услугах уретанового литья. Литье уретана - это производственный процесс, который предполагает создание деталей и компонентов с использованием полиуретановых материалов. Этот процесс обычно используется для производства прототипов, малосерийных деталей и сменных компонентов.

Доступные виды отделки для деталей, отлитых из уретана:

Уретановое литье Матовое/Матовое

Полуглянцевый

Полностью глянцевый

Пользовательская текстура

Литье уретана

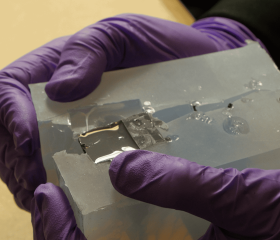

Литой силикон//Силикон долговечен, растяжим, устойчив к разрывам, инертен, легко чистится и устойчив к высоким температурам. Силиконовое литье идеально подходит для изготовления медицинских приборов, хирургических моделей, реквизита, корпусов с мягким покрытием и многого другого.

Услуги по литью уретана обычно включают следующие этапы:

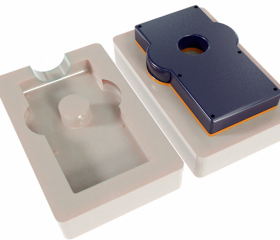

Мастер создания узоров: Мастер-шаблон нужной детали создается с помощью таких методов, как 3D-печать, обработка на станках с ЧПУ или ручное моделирование.

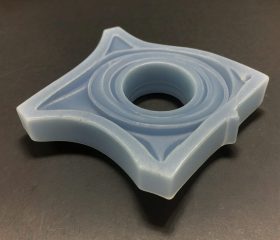

Изготовление пресс-форм: На основе мастер-шаблона создается силиконовая форма, повторяющая форму и детали детали. Готовые размеры деталей, отлитых из уретана, зависят от точности мастер-модели, геометрии детали и материала отливки. В целом, типичным является показатель усадки + 0,15%.

Смешивание материалов и литье: Полиуретановый материал смешивается и заливается в форму. Материал отверждается и застывает, образуя конечную деталь.

Отделка деталей: После процесса литья детали могут подвергаться финишной обработке, такой как обрезка, шлифовка, покраска или дополнительная обработка поверхности.

Услуги по литью уретана часто выбирают за их экономичность, быстрое время выполнения заказа и способность производить высококачественные детали со сложной геометрией. Если вы ищете компанию, которая предоставляет услуги по литью уретана, наша команда инженеров готова помочь воплотить вашу идею в жизнь - от проектирования до создания прототипа и производства.

Области применения уретанового литья

Литье уретана - это универсальный производственный процесс, который находит применение в различных отраслях промышленности благодаря своей способности производить высококачественные детали со сложной геометрией. Некоторые распространенные области применения уретанового литья включают

Создание прототипов: Литье уретана широко используется для быстрого прототипирования, позволяющего быстро изготовить функциональные прототипы для тестирования и проверки перед полномасштабным производством.

Малосерийное производство: Оно идеально подходит для мелкосерийного производства, когда традиционное литье под давлением может оказаться неэффективным с точки зрения затрат. Литье уретана позволяет эффективно производить малые и средние партии деталей.

Запасные части: Уретановое литье часто используется для создания запасных частей для машин, оборудования или продуктов, которые больше не производятся или имеют длительные сроки изготовления при традиционных методах производства.

Аэрокосмическая и оборонная промышленность: Уретановое литье используется в аэрокосмической и оборонной промышленности для производства легких компонентов, оснастки и приспособлений для самолетов, спутников и военной техники.

Автомобиль: Уретановое литье используется в автомобильной промышленности для производства прототипов деталей, нестандартных компонентов, деталей отделки салона и функциональных прототипов для тестирования.

Медицинские приборы: Медицинская промышленность использует уретановое литье для разработки прототипов и малосерийного производства деталей для медицинских приборов, хирургических инструментов, протезов и эргономичных конструкций.

Потребительская электроника: Уретановое литье популярно в индустрии бытовой электроники для создания нестандартных корпусов, кожухов, кнопок и других компонентов для электронных устройств.

Промышленное оборудование: Уретановое литье используется при производстве промышленного оборудования, деталей машин, уплотнений, прокладок и других специализированных деталей.

Архитектурные модели: Уретановое литье используется для создания архитектурных моделей, декоративных элементов, вывесок и масштабных копий для презентаций и визуализации дизайна.

Уретановое литье обеспечивает гибкость, точность и экономическую эффективность при изготовлении высококачественных деталей в сжатые сроки, что делает его предпочтительным выбором для широкого спектра применений в различных отраслях промышленности.

Другие наши производственные возможности

Мы специализируемся на 3D-печати, обработке с ЧПУ, вакуумном литье, литье под давлением и изготовлении листового металла, предлагая широкий выбор материалов и отделки поверхности.

Обработка с ЧПУ

У нас есть токарный обрабатывающий центр для композитных материалов, стандартный 3-осевой, непрерывный 5-осевой, 3+2-осевой фрезерный станок, сверление и последующая обработка более 50 различных металлов и пластиков с более чем 15 видами отделки поверхности. Допуски до ±.0000394" (0,001 мм).

Услуги по литью под давлением

HOFeng может отливать любые термопласты. Экономически эффективные услуги литья под давлением для ваших нестандартных изделий и деталей. Изготовление прототипа за 10 дней, производство за 2 недели, ISO 9001:2015 | Критические проверки качества

Услуги 3D-печати

Служба 3D-печати HOFeng - это производственный центр аддитивного производства 30+ материалов для любого применения, услуги 3D-печати Мы являемся экспертами в области 3D-печати, чтобы удовлетворить все ваши требования промышленного класса.

Услуги по литью уретана

Изготовление для быстрого прототипирования и производства деталей, детали в течение 10 дней, проверка 100% для каждой детали. Наша компания сертифицирована по ISO 9001 и обеспечивает качество каждой партии. Мы являемся экспертами по полиуретановым материалам в разработке вашей продукции.

Часто задаваемые вопросы по уретановому литью

Если вам необходимо начать литье уретана, мы готовы помочь вам от начала и до конца. Благодаря широкому спектру дополнительных услуг по постобработке и строгим мерам по обеспечению качества, применяемым нашим специализированным отделом контроля качества, вы можете быть уверены, что получите продукцию, соответствующую вашим ожиданиям.

Просто пришлите нам свои 3D-файлы CAD, и наша команда предоставит вам бесплатное предложение. Наши опытные инженеры-модельеры проведут тщательный анализ конструкции на предмет технологичности (DFM), гарантируя, что конечный продукт не только будет соответствовать вашим стандартам качества, но и уложится в рамки вашего бюджета.

Как быстро я смогу получить свои детали?

Качественные детали менее 800 штук могут быть изготовлены всего за одну неделю, если вы предоставите полные 2D и 3D модели CAD. Более сложные детали, требующие других специальных функций, займут больше времени.

Какие соображения следует учитывать при проектировании деталей для обработки на станках с ЧПУ?

При проектировании деталей для обработки на станках с ЧПУ конструкторы должны учитывать такие факторы, как доступ к инструменту, выбор материала, допуски и качество обработки поверхности.

Сколько времени обычно занимает процесс обработки с ЧПУ?

Продолжительность процесса обработки с ЧПУ зависит от таких факторов, как сложность детали, используемый материал и требуемые допуски. Она может составлять от нескольких минут до нескольких часов.

как лить уретановую резину?

Смешайте уретановый каучук: Выберите двухкомпонентный уретановый каучук, отвечающий требованиям вашего проекта по твердости, гибкости, цвету и другим свойствам. Следуйте инструкциям производителя, чтобы смешать два компонента в правильном соотношении.

Дегазация (дополнительно): Чтобы удалить пузырьки воздуха из уретаново-каучуковой смеси, можно использовать вакуумную камеру для дегазации материала. Этот шаг поможет обеспечить гладкое литье без пузырьков.

Заливка: Осторожно залейте смешанный уретаново-каучуковый материал в форму. Заливайте медленно и равномерно, чтобы в смеси не оставалось пузырьков воздуха.

Отверждение: Дайте уретановой резине отвердеть и затвердеть в соответствии с инструкциями производителя. Время отверждения может варьироваться в зависимости от конкретного типа используемой уретановой резины и условий окружающей среды, таких как температура и влажность.

Извлечение: После полного отверждения уретанового каучука аккуратно извлеките деталь из формы. В зависимости от сложности формы и конструкции детали вам может потребоваться использование разделительных агентов или методов, облегчающих извлечение.

Постобработка (по желанию): После формовки вы можете обрезать излишки материала, очистить деталь и выполнить любые дополнительные действия по обработке, такие как покраска, отделка или сборка, если это необходимо.

Тестирование и контроль качества: Проверьте деталь из литой уретановой резины на наличие дефектов, дефектов поверхности, размеров и общего качества. Проведите все необходимые испытания, чтобы убедиться, что деталь соответствует требуемым спецификациям и критериям производительности.

Следуя этим рекомендациям и принимая надлежащие меры предосторожности, вы сможете успешно отливать детали из уретановой резины для различных применений, таких как прототипы, промышленные компоненты, пресс-формы, уплотнения, прокладки и многое другое.

Каких сертификатов или промышленных стандартов вы придерживаетесь в своих процессах обработки с ЧПУ?

Компания HOFeng сертифицирована по стандарту ISO 9001, соответствует требованиям стандарта ISO 13485.

Каких допусков могут достичь ваши станки с ЧПУ?

Наши станки способны выдерживать допуски до +/- 0,0002 дюйма.

сколько стоит литье под давлением?

Расчет стоимости литья под давлением включает множество факторов, в том числе дизайн изделия, стоимость сырья, трудозатраты, амортизацию оборудования и т. д.

Дизайн изделия: Сложность, размер, форма и другие факторы влияют на стоимость литья под давлением. Для некоторых сложных изделий могут потребоваться специальные пресс-формы и технологии обработки, соответственно, возрастет и стоимость.

Стоимость сырья: Различные виды пластикового сырья имеют разную цену, а также зависят от таких факторов, как спрос и предложение на рынке. Сырьевые материалы составляют значительную часть затрат на литье под давлением.

Стоимость пресс-формы: литье под давлением требует использования специально изготовленных пресс-форм. На стоимость влияет дизайн, изготовление и стоимость обслуживания пресс-формы.

Трудозатраты: Управление термопластавтоматом и последующая обработка требуют ручного труда. Затраты на оплату труда - это часть стоимости литья под давлением, которую нельзя игнорировать.

Потребление энергии: Машины для литья под давлением потребляют большое количество энергии, такой как электричество и сжатый воздух. Затраты на энергию также являются важной частью расходов на литье под давлением.

почему уретановое литье

Литье уретана, также известное как литье полиуретана, - это популярный производственный процесс, используемый для создания высококачественных, точных и долговечных пластиковых деталей и прототипов. Существует несколько причин, по которым уретановое литье выбирают вместо других методов производства, таких как литье под давлением или 3D-печать:

Экономичность: Литье уретана - экономически выгодная альтернатива литью под давлением для малосерийного производства. Оно не требует дорогостоящей оснастки, пресс-форм и затрат на установку, что делает его идеальным для производства небольших партий деталей без больших предварительных инвестиций.

Быстрое изготовление: Литье уретана позволяет быстро создавать прототипы и изготавливать детали с более коротким сроком выполнения заказа по сравнению с традиционными методами производства. Это делает его предпочтительным выбором для проектов, требующих быстрого выполнения.

Точность и аккуратность: Уретановое литье позволяет получать детали с высокой точностью и аккуратностью, что делает его пригодным для применения в тех областях, где требуются жесткие допуски и сложные детали. Детали могут быть воспроизведены с неизменным качеством и точностью размеров.

Широкий выбор материалов: Уретановое литье предлагает множество вариантов материалов с различными свойствами, такими как гибкость, твердость и ударопрочность. Такая многогранность позволяет подстраиваться под конкретные требования проекта и выбирать наиболее подходящий материал.

Отделка поверхности: Уретановое литье позволяет получить широкий спектр поверхностей, включая матовые, матовые, глянцевые или текстурированные. Это позволяет настраивать внешний вид и ощущение деталей, повышая их эстетическую привлекательность.

Сложные геометрии: Литье уретана позволяет получать детали со сложной геометрией, вырезами, тонкими стенками и замысловатыми элементами, которые сложно изготовить другими методами. Такая универсальность делает его пригодным для широкого спектра применений в различных отраслях промышленности.

Малосерийное производство: Литье уретана хорошо подходит для мелкосерийного производства, тестирования прототипов и промежуточного производства между итерациями дизайна. Оно обеспечивает гибкость при масштабировании объемов производства в зависимости от спроса, не требуя больших минимальных объемов заказа.

В целом, литье уретана - это универсальный, экономичный и эффективный производственный процесс, который предлагает множество преимуществ для создания пластиковых деталей и прототипов с высоким качеством, точностью и возможностями настройки. Он широко используется в таких отраслях, как автомобилестроение, аэрокосмическая промышленность, производство медицинского оборудования, бытовой электроники и т. д. для изготовления функциональных прототипов, деталей и компонентов конечного использования.