Services de fabrication de prototypes de tôle

HOFeng peut vous aider à fabriquer rapidement et avec précision vos boîtiers, supports, assemblages, pièces soudées, armoires, boîtiers et autres pièces de tôlerie et prototypes.

PAS DE MOQ (quantité minimale de commande)

100% inspection de chaque pièce

Les fichiers que vous téléchargez sont strictement confidentiels et sécurisés

Applications pour la fabrication de tôles

Nous disposons de plus de 60 machines CNC dans notre usine

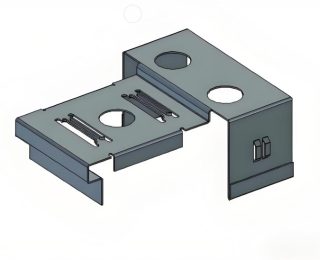

Prototypes en tôle

Prototypes en tôle

Que vous ayez besoin d'un

support, châssis

l'enceinte, ou tout autre

tôle complexe

conception, nous pouvons répondre à vos besoins

Produits en tôle

Produits en tôle

Notre production à faible volume

L'installation peut produire jusqu'à

60 à 1500+tôle

dans un délai de 10 jours.

Assemblages en plusieurs parties

Grâce à notre personnel expérimenté et à nos protocoles de qualité rigoureux, nous pouvons garantir que Sheet Metal Products livrera un produit fini conforme dès la première fois.

Matériaux de prototypage de tôles - Fabrication de tôles en Chine

En tant que leader de la fabrication de tôles en Chine, HOFeng a 15 ans d'expérience dans la fabrication de tôles, vous aidant à fournir des produits métalliques de précision de haute qualité à des prix compétitifs. HOFeng propose une variété de matériaux de fabrication de tôles, y compris l'acier inoxydable, l'aluminium, le cuivre, le laiton et l'acier galvanisé, et nous pouvons aider les clients à choisir celui qui convient à leurs projets de prototypage.

Qu'est-ce que le prototypage de tôles ?

La transformation de la tôle est une méthode de formage à froid et à chaud, d'assemblage et de raccordement de plaques, de profilés et de tuyaux métalliques pour fabriquer des composants métalliques par soudage, rivetage et boulonnage. Elle comprend principalement le travail à l'établi, l'emboutissage, le découpage des métaux, le soudage, le traitement thermique, le traitement de surface, le rivetage, l'assemblage et d'autres types de travaux professionnels.

Capacités complètes de prototypage de HOFeng

Notre usine couvre une superficie de 6 000+ mètres carrés, avec des installations matérielles et logicielles complètes, y compris plus de 60 poinçonneuses, 30 centres d'usinage CNC, 3 machines de découpe au laser et plusieurs machines de pliage CNC.Nous avons des machines impliquent la coupe, le pliage, le poinçonnage, le perçage, la soudure et le formage. Nos machines peuvent éliminer efficacement les bavures et les arêtes vives, le meulage de précision,le ponçage à large bande,pour améliorer la sécurité et l'esthétique de vos composants en tôle,pour garantir que vos produits en tôle répondent aux normes les plus strictes.

En outre, nous offrons une variété de finitions, y compris le revêtement en poudre, le placage et l'anodisation. Nous proposons également une découpe laser spécialisée,

Découpe au jet d'eau, électroérosion par fil, photogravure chimique, poinçonnage et services de formage. Notre équipe d'ingénieurs et de techniciens qualifiés se consacre à fournir à nos clients des pièces de la plus haute qualité et un excellent service à la clientèle. Que vous ayez besoin de quelques prototypes ou d'un faible volume de production, nous sommes votre interlocuteur unique pour tous vos besoins en matière de fabrication de tôles. Contactez-nous dès aujourd'hui pour un devis gratuit !

Processus de finition de la tôle

1. finition standard

Meulage et polissage

Brossage

2. Sablage de perles

3. Anodisation

Anodisation (type II ou type III)

Chromate

Zinc

Passivation

Nickel chimique

Etain

La classe 1 correspond aux produits non teintés et la classe 2 aux produits teintés.

les revêtements. Bien que le noir soit la couleur la plus populaire du type 2

anodisation, Il y a les transparents, les bleus, les rouges, les dorés, les jaunes,

orange, vert, violet,

et d'autres pigments disponibles.

La classe 1 correspond à une couche dure transparente, tandis que la classe 2 correspond à

un poil dur noir.

4. Revêtement par film chimique

5. revêtement par poudre

6. PlacageLes options de placage (ou de revêtement) peuvent offrir une résistance à la corrosion, améliorer les propriétés d'usure et contribuer à la conductivité, tout en améliorant l'apparence grâce à une finition uniforme et de qualité.

Les options de placage disponibles sont les suivantes :

Anodisation (type II ou type III)

Chromate

Zinc

Passivation

Nickel chimique

Etain

7. Trame de soie

Ce procédé est souvent utilisé pour ajouter des étiquettes, des instructions ou des motifs décoratifs aux produits métalliques fabriqués.

8. Grenaillage de précontrainte 9 Assemblage et mise en kit

Nos autres capacités de fabrication

Nous sommes spécialisés dans l'impression 3D, l'usinage CNC, le moulage sous vide, le moulage par injection et la fabrication de tôles, et proposons une grande variété de matériaux et de finitions de surface.

Usinage CNC

Nous disposons d'un centre d'usinage composite Mill-turn, d'une fraiseuse standard à 3 axes, d'une fraiseuse continue à 5 axes, d'une fraiseuse à 3+2 axes, d'un système de perçage et de post-traitement utilisant plus de 50 métaux et plastiques différents, disponibles dans plus de 15 finitions de surface. Tolérances jusqu'à ± 0,001 mm (0,0000394").

Services de moulage par injection

HOFeng peut mouler n'importe quel thermoplastique. Des services de moulage par injection rentables pour vos produits et pièces sur mesure. Outil prototype en moins de 10 jours Outil de production en moins de 2 semaines, ISO 9001:2015 | Critique pour les inspections de qualité

Service d'impression 3D

Le service d'impression 3D de HOFeng est votre centre de production de fabrication additive pour plus de 30 matériaux pour toutes les applications, service d'impression 3D. Nous sommes des experts en impression 3D pour répondre à toutes vos exigences de qualité industrielle.

Services de coulée d'uréthane

Nous fabriquons des prototypes et des pièces rapidement, dans un délai de 10 jours, avec une inspection 100% pour chaque pièce. Notre certification ISO 9001 nous permet d'offrir une qualité de haut niveau pour chaque lot.

Vous demandez, nous répondons

Services de fabrication de tôles

Le prototypage de tôles peut accélérer le développement de votre projet grâce à des itérations de conception rapides, flexibles et fiables, à des fonctionnalités d'essai et au passage rapide du concept au marché.