Devis le plus rapide en téléchargeant des données 3D

Découpage et formage des métaux

- Permet le pliage complexe et le traitement au laser de formes spéciales

- S'adapter à divers matériaux et traitements de surface Livraison rapide en 1 jour, même pour une seule pièce

Les fichiers que vous téléchargez sont strictement confidentiels et sécurisés

Service de découpage et de formage des métaux

Travailler avec diverses méthodes de traitement et formes spéciales telles que la découpe au laser, le poinçonnage et l'emboîtement CNC, le cintrage et la pulvérisation.

Travailler avec diverses méthodes de traitement et formes spéciales telles que la découpe au laser, le poinçonnage et l'emboîtement CNC, le cintrage et la pulvérisation.

Travailler avec différents matériaux tels que l'acier inoxydable, l'acier au carbone et les alliages d'aluminium.

Capable d'identifier automatiquement les types de trous.

Capacités de fabrication de tôles

HOFeng est équipé d'un robot de soudage au CO2, d'un robot de polissage, d'un robot de soudage au laser, d'une plate-forme de soudage au laser, d'une machine de découpe au laser, d'une machine de soudage au laser portative, d'une poinçonneuse CNC, d'une plieuse, d'une ébavureuse automatique afin d'améliorer la vitesse et la capacité à faire face aux applications de production de masse.

grands fabricants de tôles

Usinage de châssis et d'armoires en tôle

Des décennies d'expertise dans la fabrication de tôles

Si vous êtes à la recherche d'un fabricant de tôles capable de prendre en charge tous vos projets, du développement de nouveaux produits et de pièces prototypes aux grandes séries et aux services d'assemblage, HOFeng est un partenaire de choix. Nos experts gèrent toutes les étapes du processus, de l'aide à la conception et de la fabrication de tôles à la peinture, la sérigraphie, l'assemblage et la mise en place de sous-ensembles.

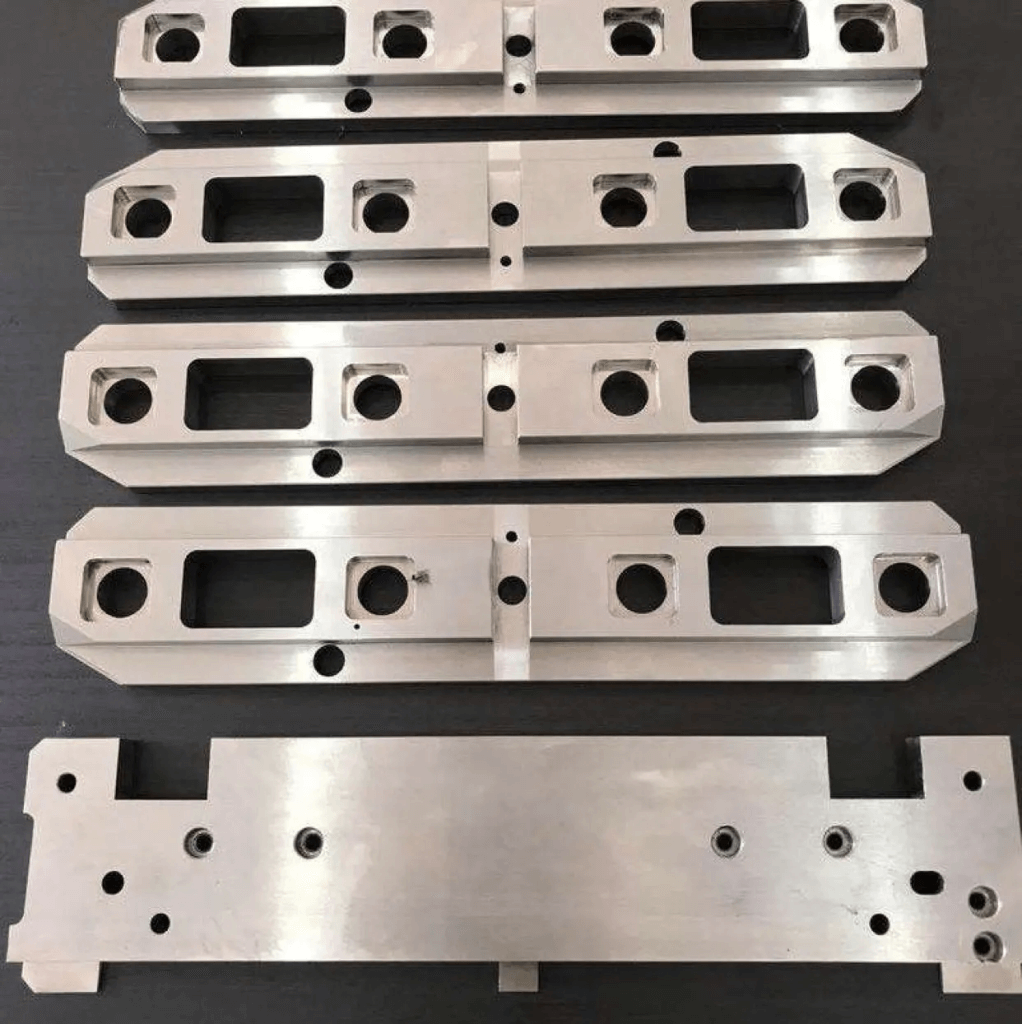

Poinçonnage CNC

Nos poinçonneuses à commande numérique peuvent transformer avec précision des caractéristiques standard et des formes complexes en tôle pour répondre à vos besoins. La poinçonneuse à tourelle que nous utilisons peut poinçonner jusqu'à une épaisseur de 1/4 de pouce et nous pouvons également produire des caractéristiques spéciales telles que des fraises, des bourrelets et des persiennes.

pliage de tôles

ISO9001

Délai d'exécution aussi court qu'un jour

Aluminium, acier, acier inoxydable et autres

La plieuse de tôle est principalement utilisée pour plier la tôle en ligne droite. Le processus de pliage à la presse est principalement utilisé pour le traitement de pièces avec des lots de production importants, des formes complexes et des exigences de précision élevées.

Nos services de cintrage permettent de réaliser des angles précis et d'obtenir un produit final respectant des tolérances serrées.

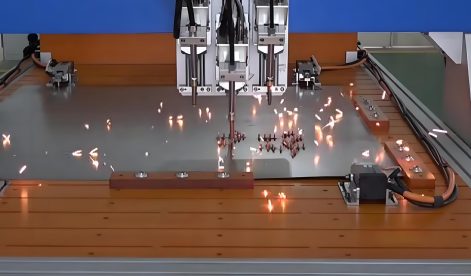

service de découpe au laser fabrication de tôles

La découpe laser utilise un laser puissant qui est intensifié par des lentilles ou des miroirs. Il s'agit d'une machine précise et économe en énergie qui convient pour les tôles fines ou de moyenne épaisseur, mais qui peut avoir des difficultés à pénétrer les matériaux les plus durs.

Découpe au jet d'eau

La découpe au jet d'eau est une méthode de fabrication de tôles qui utilise un jet d'eau à haute pression (mélangé à une substance abrasive) pour découper le métal. Le service de découpe au jet d'eau de HOFeng est une solution polyvalente et rentable pour les pièces métalliques de précision découpées avec un degré élevé de précision. Nos machines à jet d'eau grand format peuvent découper des matériaux d'une épaisseur allant jusqu'à 6 pouces avec une tolérance de 0,005″- 0,015″.

Découpe plasma CNC

La découpe au plasma est plus efficace pour la découpe des métaux non ferreux (acier inoxydable, aluminium, cuivre, titane, nickel) ; son principal avantage est que lors de la découpe de métaux de faible épaisseur, la vitesse de découpe au plasma est rapide, en particulier pour la découpe de plaques minces d'acier au carbone ordinaire.Le service de découpe au plasma de HOFeng peut fournir des pièces complexes de haute précision sur des matériaux tels que l'aluminium, l'acier et l'acier inoxydable.

Electro-érosion par enfonçage et par fil

L'électroérosion par enfonçage consiste à utiliser des décharges électriques pour éroder la surface de la pièce afin de créer les formes souhaitées. En revanche, l'électroérosion à fil utilise un fil fin pour découper la pièce, ce qui convient à l'usinage de haute précision et de formes complexes. Il répond aux exigences de haute précision dans la fabrication des pièces et améliore l'efficacité de la production.

Variété de méthodes de soudage

HOFeng dispose de quatre techniques de soudage principales : TIG (gaz inerte de tungstène), MIG (gaz inerte métallique), MAG (gaz actif métallique) et soudage au CO2. Chacune de ces méthodes offre des avantages uniques et convient à différentes applications de soudage, allant du soudage de précision à la fabrication lourde.

Finition de surface et assemblage

Le terme "finition de surface" désigne les procédés utilisés pour améliorer l'aspect, la durabilité de la surface et la résistance à la corrosion d'un produit. Ces options de finition comprennent le revêtement par poudre, l'anodisation, le placage, le polissage, le brossage et bien d'autres encore. La finition de surface est essentielle pour améliorer la qualité globale et l'esthétique du produit final, ainsi que pour le protéger des facteurs environnementaux tels que la rouille et la corrosion.

Les "processus secondaires" désignent des opérations ou des services supplémentaires qui peuvent être nécessaires une fois le processus de fabrication initial achevé. Ces processus secondaires peuvent inclure des activités telles que le pliage CNC, le meulage, le taraudage, le moletage, etc. Ces services sont essentiels pour obtenir les spécifications et les normes de qualité souhaitées pour le produit final.

Matériaux de fabrication métallique

Nos autres capacités de fabrication

Nous sommes spécialisés dans l'impression 3D, l'usinage CNC, le moulage sous vide, le moulage par injection et la fabrication de tôles, et proposons une grande variété de matériaux et de finitions de surface.

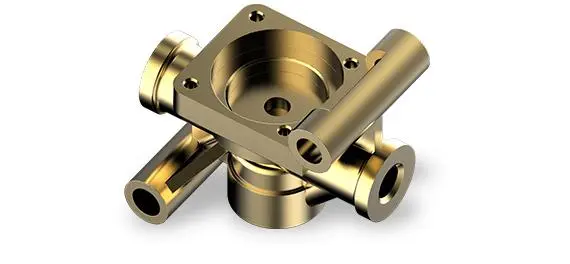

Usinage CNC

Nous disposons d'un centre d'usinage composite Mill-turn, d'une fraiseuse standard à 3 axes, d'une fraiseuse continue à 5 axes, d'une fraiseuse à 3+2 axes, d'un système de perçage et de post-traitement utilisant plus de 50 métaux et plastiques différents, disponibles dans plus de 15 finitions de surface. Tolérances jusqu'à ± 0,001 mm (0,0000394").

Services de moulage par injection

HOFeng peut mouler n'importe quel thermoplastique. Des services de moulage par injection rentables pour vos produits et pièces sur mesure. Outil prototype en moins de 10 jours Outil de production en moins de 2 semaines, ISO 9001:2015 | Critique pour les inspections de qualité

Service d'impression 3D

Le service d'impression 3D de HOFeng est votre centre de production de fabrication additive pour plus de 30 matériaux pour toutes les applications, service d'impression 3D. Nous sommes des experts en impression 3D pour répondre à toutes vos exigences de qualité industrielle.

Services de coulée d'uréthane

Nous fabriquons des prototypes et des pièces rapidement, dans un délai de 10 jours, avec une inspection 100% pour chaque pièce. Notre certification ISO 9001 nous permet d'offrir une qualité de haut niveau pour chaque lot.

Pourquoi choisir HoFeng

Précision et exactitude

1. Nos machines de précision et nos logiciels de pointe garantissent la précision et la cohérence de chaque produit que nous créons.

2. Des processus stricts de contrôle de la qualité garantissent que chaque produit répond à nos normes élevées et est exactement conforme aux spécifications.

Réponse rapide

1. Une équipe d'ingénieurs et d'opérateurs expérimentés

2. Atelier d'usinage interne, fonctionnant 24 heures sur 24 et 7 jours sur 7

3. Délai d'exécution rapide, la haute qualité est notre priorité absolue.

4. Vous aider à établir des devis instantanés, à produire et à livrer.

Assurance qualité

1. Notre système de gestion de la qualité, certifié ISO 9001, garantit la fiabilité de nos produits.

2. Toutes les pièces sont contrôlées sur le plan dimensionnel à l'aide d'un équipement calibré afin de répondre exactement à vos spécifications.

3.250+Projets Livré par mois,10000+SQ ZONE DE MÉTRO, 15+ ANNÉES DE SERVICE