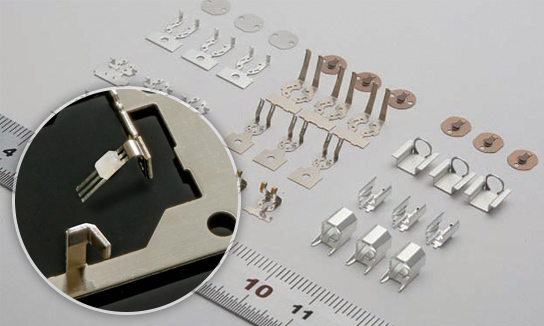

Штамповка металла для электронной промышленности

- Услуги по изготовлению деталей из листового металла для электронной промышленности

- Опередите конкурентов на рынке благодаря быстрому созданию прототипов и производству по требованию

- Многочисленные варианты отделки, такие как анодирование и порошковое покрытие

Преимущества штамповки металла для электронной промышленности

Обработка листового металла - это технология обработки, при которой к тонким металлическим пластинам прикладывается усилие для их деформации. В результате резки, гибки, растяжения, штамповки, экструзии и других процессов получаются детали определенных форм и размеров. Обработка листового металла широко используется в обрабатывающей промышленности. Производство оборудования, автомобилей, коммуникационной электроники, бытовой техники, судостроение и другие отрасли промышленности неотделимы от обработки листового металла. Металлические штампованные изделия широко используются в индустрии бытовой электроники, включая смартфоны, ноутбуки, планшеты, а также новое поколение потребительских электронных продуктов, таких как умные беспроводные наушники, умные часы, умные колонки, устройства VR и т.д.

Наш процесс штамповки металла

Процесс штамповки металла включает в себя резку листа, формовку, штамповку, гибку, формовку, очистку и обработку поверхности. Формовка является основным этапом процесса штамповки металла, который требует изготовления соответствующих штампов в соответствии с чертежами изделия и формовки металлических листов.

Оборудование, необходимое для штамповки металла, включает в себя штамповочные машины, штампы, отрезные станки, гибочные станки, профилировочные станки, очистительные машины, устройства для обработки поверхности и т. д. Штамповочная обработка металла широко используется в таких отраслях, как автомобилестроение, электроника и машиностроение, например, для изготовления кузовных деталей автомобилей, корпусов электроники, механических компонентов и т.д.

Вторичные операции:

Предварительное, последующее, точечное и другие виды непрерывного гальванического и роликового покрытия медь-никель-олово-золото

Индивидуальная упаковка

Непрерывная рулонная штамповка и гальваническое покрытие

Термообработка

Почему HOFeng для развития индустрии бытовой электроники

Прецизионные изделия HOFeng - это в основном индивидуальные изделия, разработанные, оснащенные, отштампованные и обработанные в соответствии с требованиями заказчика. Благодаря опыту в производстве точных и мелкосерийных изделий, а также тщательному управлению процессом, продукция обладает высокой точностью и хорошо совместима с отраслью бытовой электроники.

Мы унаследовали наш дух за более чем 15 лет, накопив богатый опыт в обработке штамповки.

У нас есть 23 штамповочных станка.

У нас есть системы измерения изображений, автоматические системы измерения.

Оптические шлифовальные станки, медленная резка проволоки и многое другое.

Наши штампованные детали соответствуют стандартам:.

В основном настраивается по чертежам, мы предоставляем клиентам удовлетворительные продукты в соответствии с требованиями заказчика, и допуск соответствует требованиям чертежей. Соответствует стандартам ROHS и REACH.

В отрасли бытовой электроники мы используем такие материалы, как:

Сплав нержавеющей стали

Высоконикелевый сплав

Алюминиевый сплав

Легированный чугун

ПЭТ

Толщина материала варьируется от 0,02 до 2,0 миллиметров.

Другие наши производственные возможности

Мы специализируемся на 3D-печати, обработке с ЧПУ, вакуумном литье, литье под давлением и изготовлении листового металла, предлагая широкий выбор материалов и отделки поверхности.

Обработка с ЧПУ

У нас есть токарный обрабатывающий центр для композитных материалов, стандартный 3-осевой, непрерывный 5-осевой, 3+2-осевой фрезерный станок, сверление и последующая обработка более 50 различных металлов и пластиков с более чем 15 видами отделки поверхности. Допуски до ±.0000394" (0,001 мм).

Услуги по литью под давлением

HOFeng может отливать любые термопласты. Экономически эффективные услуги литья под давлением для ваших нестандартных изделий и деталей. Изготовление прототипа за 10 дней, производство за 2 недели, ISO 9001:2015 | Критические проверки качества

Услуги 3D-печати

Служба 3D-печати HOFeng - это производственный центр аддитивного производства 30+ материалов для любого применения, услуги 3D-печати Мы являемся экспертами в области 3D-печати, чтобы удовлетворить все ваши требования промышленного класса.

Услуги по литью уретана

Изготовление для быстрого прототипирования и производства деталей, детали в течение 10 дней, проверка 100% для каждой детали. Наша компания сертифицирована по ISO 9001 и обеспечивает качество каждой партии. Мы являемся экспертами по полиуретановым материалам в разработке вашей продукции.