Резка и формовка металла

Самое быстрое составление сметы путем загрузки 3D-данных

- Подходят для различных материалов и обработки поверхностей Быстрая доставка за 1 день, даже за 1 штуку

-Файлы, которые вы загружаете, строго конфиденциальны и безопасны

-Возможность сложной гибки и лазерной обработки специальных форм

Что такое гибка листового металла?

Гибка листового металла - это процесс, при котором к металлическому листу прикладывается усилие для создания нужного радиуса. Преимущество этой технологии заключается в том, что она позволяет создавать различные геометрические формы деталей без использования специализированной оснастки. Для достижения этой цели в основном используется листогибочный пресс - распространенное оборудование в этой области.

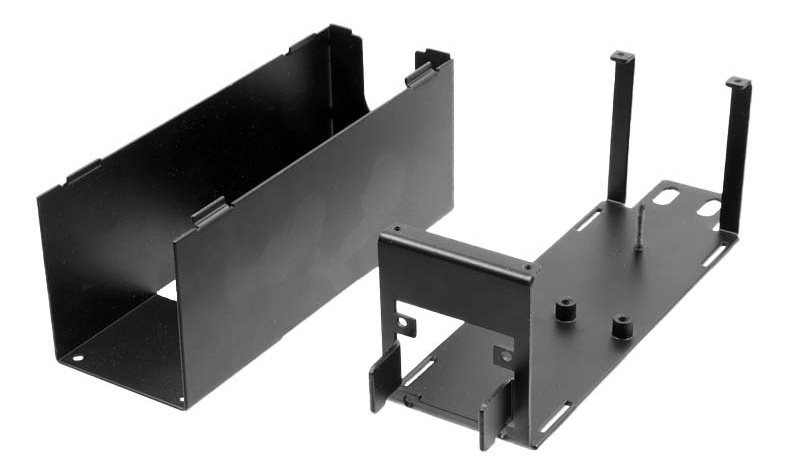

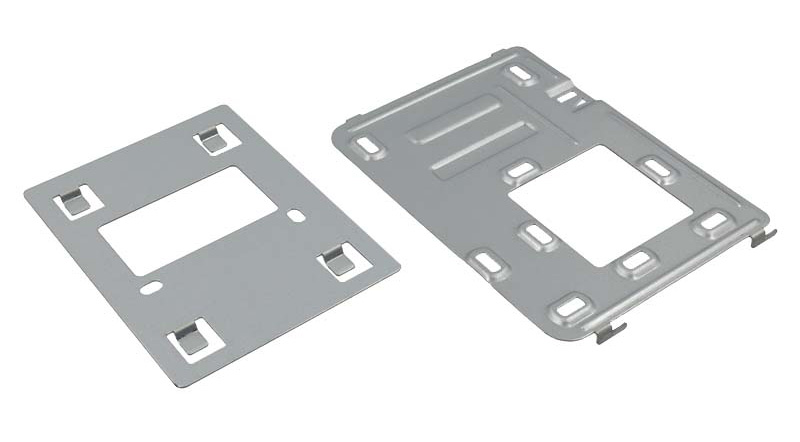

Сферы применения гибки листового металла обширны и разнообразны и охватывают производство многочисленных промышленных и потребительских товаров. Например, она широко используется при изготовлении кузовных панелей, холодильных установок, электронных корпусов и кронштейнов. Его универсальность позволяет производителям создавать сложные конструкции и формы, которые нелегко достичь другими методами.

Кроме того, гибка листового металла особенно хорошо подходит для сценариев с меньшими объемами производства или использованием более тонких металлических листов. В таких случаях методы литья могут оказаться неэффективными и нецелесообразными, что делает гибку листового металла более приемлемым вариантом. Это особенно актуально для серий от нескольких сотен до нескольких тысяч изделий в партии.

Услуги по гибке труб

Гибка труб состоит из ряда производственных процессов, которые изменяют форму трубы или трубки для создания желаемой геометрии или характеристик, отвечающих определенным требованиям. HOFeng предлагает услуги по гибке труб и изготовлению металлических труб и трубных заготовок для удовлетворения ваших потребностей.

Как гнуть листовой металл

1. Гибка листового металла обычно осуществляется с помощью дорогостоящих специализированных инструментов, известных как листогибы. Гибка листового металла вручную - вполне выполнимая задача, если кусок листового металла достаточно мал и тонок, чтобы с ним можно было справиться.

2.Гибка труб

Обычно используются такие методы гибки труб, как гибка на прессе, гибка вальцами, гибка с возвратом и гибка экструзией.

3.Сгибание профилей

Профили на самолетах в основном используются для изготовления каркасов (крылья фюзеляжа и переборки воздухозаборника, усиливающие кромки и т.д.), которые делятся на две категории: экструдированные профили и профили для гибки листов. Экструдированные профили для прокатки можно разделить на два типа: равной кривизны и переменной кривизны. К часто используемым профилям относятся угловые и Т-образные профили.

Типы материалов для изготовления листового металла

Наша компания специализируется на производстве деталей из листового металла, используя в качестве основных материалов алюминий, нержавеющую сталь и стальные сплавы. Эти металлы обладают превосходной долговечностью, коррозионной стойкостью и прочностью, что делает их идеальными для различных применений. Мы также накопили большой опыт работы с латунью и бронзой. По запросу мы можем поставлять другие виды листового металла.Алюминий 5052, 5754, Нержавеющая сталь 304, 316L,Мягкая сталь 1018,Медь C110

Отделка поверхностей и сборка

Под "отделкой поверхности" понимаются процессы, используемые для улучшения внешнего вида, долговечности поверхности и коррозионной стойкости изделия. Эти варианты отделки включают порошковое покрытие, анодирование, гальванизацию, полировку, браширование и многое другое. Отделка поверхности необходима для повышения общего качества и эстетики конечного продукта, а также для защиты его от таких факторов окружающей среды, как ржавчина и коррозия.

"Вторичные процессы" относятся к дополнительным операциям или услугам, которые могут потребоваться после завершения первоначального производственного процесса. Эти вторичные процессы могут включать такие операции, как гибка с ЧПУ, шлифовка, нарезание резьбы, накатка и т. д. Эти услуги необходимы для достижения желаемых технических характеристик и стандартов качества конечного продукта.

Другие наши производственные возможности

Мы специализируемся на 3D-печати, обработке с ЧПУ, вакуумном литье, литье под давлением и изготовлении листового металла, предлагая широкий выбор материалов и отделки поверхности.

Обработка с ЧПУ

У нас есть токарный обрабатывающий центр для композитных материалов, стандартный 3-осевой, непрерывный 5-осевой, 3+2-осевой фрезерный станок, сверление и последующая обработка более 50 различных металлов и пластиков с более чем 15 видами отделки поверхности. Допуски до ±.0000394" (0,001 мм).

Услуги по литью под давлением

Hofengfab может отлить любой термопластик. Экономически эффективные услуги литья под давлением для ваших изделий и деталей, изготовленных на заказ. Изготовление прототипа за 10 дней, производство за 2 недели, ISO 9001:2015 | Критические проверки качества

Услуги 3D-печати

Служба 3D-печати Hofengfab - это ваш производственный центр аддитивного производства 30+ материалов для любого применения, услуги 3D-печати Мы являемся экспертами в области 3D-печати, чтобы удовлетворить все ваши требования промышленного класса.

Услуги по литью уретана

Изготовление для быстрого прототипирования и производства деталей, детали в течение 10 дней, проверка 100% для каждой детали. Наша компания сертифицирована по ISO 9001 и обеспечивает качество каждой партии. Мы являемся экспертами по полиуретановым материалам в разработке вашей продукции.