Transforme as suas ideias em produtos de alta qualidade

A HOFeng pode moldar qualquer termoplástico. Serviços de moldagem por injeção rentáveis para os seus produtos e peças personalizados.

Mais de 15 anos de experiência no fabrico de produtos personalizados, seguindo as normas ISO

- Ferramenta de protótipo em apenas 10 dias

- Ferramenta de produção em apenas 2 semanas

- ISO 9001:2015 | Crítica para as inspecções de qualidade

- Entre em contacto com as suas necessidades específicas de resina.

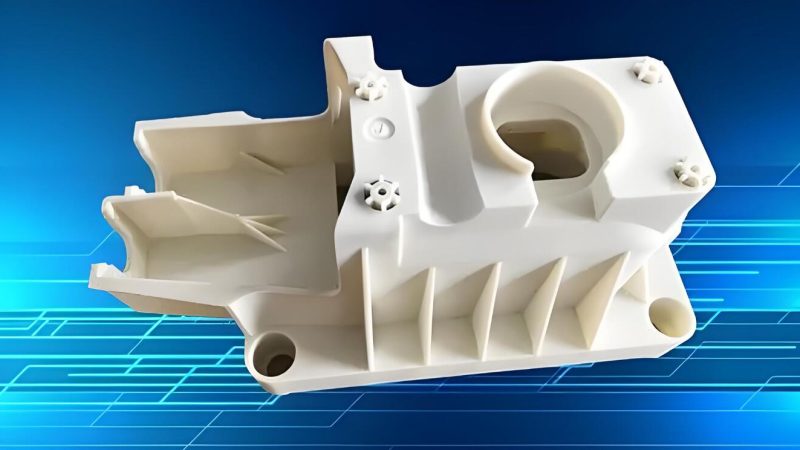

o que é a moldagem por injeção?

A moldagem por injeção é um método de moldagem que combina injeção e moldagem, também conhecido como moldagem por injeção. O método geral de moldagem por injeção consiste em colocar grânulos ou pós de componentes poliméricos no cilindro de uma máquina de moldagem por injeção, onde são submetidos a processos de aquecimento, compressão, cisalhamento, mistura e transporte. Em seguida, com a ajuda de um êmbolo ou parafuso, é aplicada pressão à massa fundida de polímero. O polímero fundido a alta temperatura é então injetado numa cavidade pré-fechada do molde a baixa temperatura através do bocal na frente do cilindro e do sistema de fecho do molde. Após o arrefecimento e a solidificação, o molde pode ser aberto, o produto pode ser ejectado e podem ser obtidos produtos de plástico com determinadas formas geométricas e precisão. A moldagem por injeção é utilizada para criar muitas coisas, tais como caixas electrónicas, recipientes, tampas de garrafas, interiores de automóveis, pentes e a maioria dos outros produtos de plástico disponíveis atualmente.

Aplicações de moldagem por injeção

As peças de injeção de plástico têm um elevado rendimento e uma vasta aplicação. Isto deve-se ao facto de as peças de plástico terem algum valor prático em comparação com as peças de metal. Os plásticos são amplamente utilizados como componentes estruturais de engenharia, tais como caixas, armações e bases para instrumentos electrónicos, automóveis, electrodomésticos e equipamento de comunicação, utilizados para proteger, melhorar e construir uma vasta gama de produtos. O processo é conhecido pelas suas capacidades de rapidez, precisão e eficiência e tornou-se um dos serviços de fabrico mais populares para a produção de peças de plástico.

Opções de pós-processamento e acabamento

O tratamento de superfície na moldagem por injeção refere-se ao processo de aplicação de um tratamento ou revestimento específico à superfície de uma peça maquinada, como a pintura ou as pastilhas de troca a quente.

Inserções. Impressão em bloco. Pintura. Serigrafia. Soldadura por ultra-sons. Gravação a laser. Revestimento UV. Estampagem a quente. Maquinação pós-molde.

Capacidades de moldagem por injeção de plástico

A nossa máquina de moldagem por injeção:

Máquina de moldagem por injeção de alta velocidade

Máquina de moldagem por injeção especial de PVC

Máquina de moldagem por injeção especial PET

Máquina de moldagem por injeção de duas cores

Somos capazes de preservar uma tolerância de maquinação de +/- 0,003 polegadas (0,08 mm), incorporando também uma tolerância de resina que se situa num intervalo superior a, mas nunca inferior a, +/- 0,002 polegadas por polegada (0,002 mm por mm).

Para resolver este problema, utilizamos técnicas de maquinação avançadas e equipamento de precisão para garantir que as nossas tolerâncias são cumpridas com a máxima exatidão. A tolerância de maquinagem de +/- 0,003 polegadas (0,08 mm) garante que o produto acabado cumpre as especificações exigidas, enquanto a tolerância de resina incluída de +/- 0,002 polegadas por polegada (0,002 mm por mm) permite um grau de flexibilidade no próprio material.

Ao manter estas tolerâncias apertadas, conseguimos fornecer produtos de alta qualidade que satisfazem as exigências dos nossos clientes. Quer se trate de aplicações industriais ou de fabrico de precisão, esforçamo-nos por exceder as expectativas e apresentar resultados excepcionais.

Materiais de moldagem por injeção de plástico

Propriedade:

resistente a impactos

Resistente ao desgaste

Estabilidade dimensional

Resistência química

Tipo borracha

Económico

Cosmética

Materiais:

ABS, PMMA, PVC, PE, PC

POM, PEEK, UHMW

ABDOMINAIS, PBT, ANCAS, PPS

PEEK, PP, PBT, PE, LDPE, PA

TPU, TPE, Silicone

PP, PEAD, PEBD

ABS, PC, HIPS

Dimensões máximas:

Tamanho:480mm x 751mm

Volume:966.837 cu.mm

Profundidade:101mm a partir da linha de separação

Área de molde projectada:112.903 mm².

As nossas outras capacidades de fabrico

Somos especializados em impressão 3D, maquinagem CNC, fundição a vácuo, moldagem por injeção e fabrico de chapas metálicas, oferecendo uma grande variedade de materiais e acabamentos de superfície.

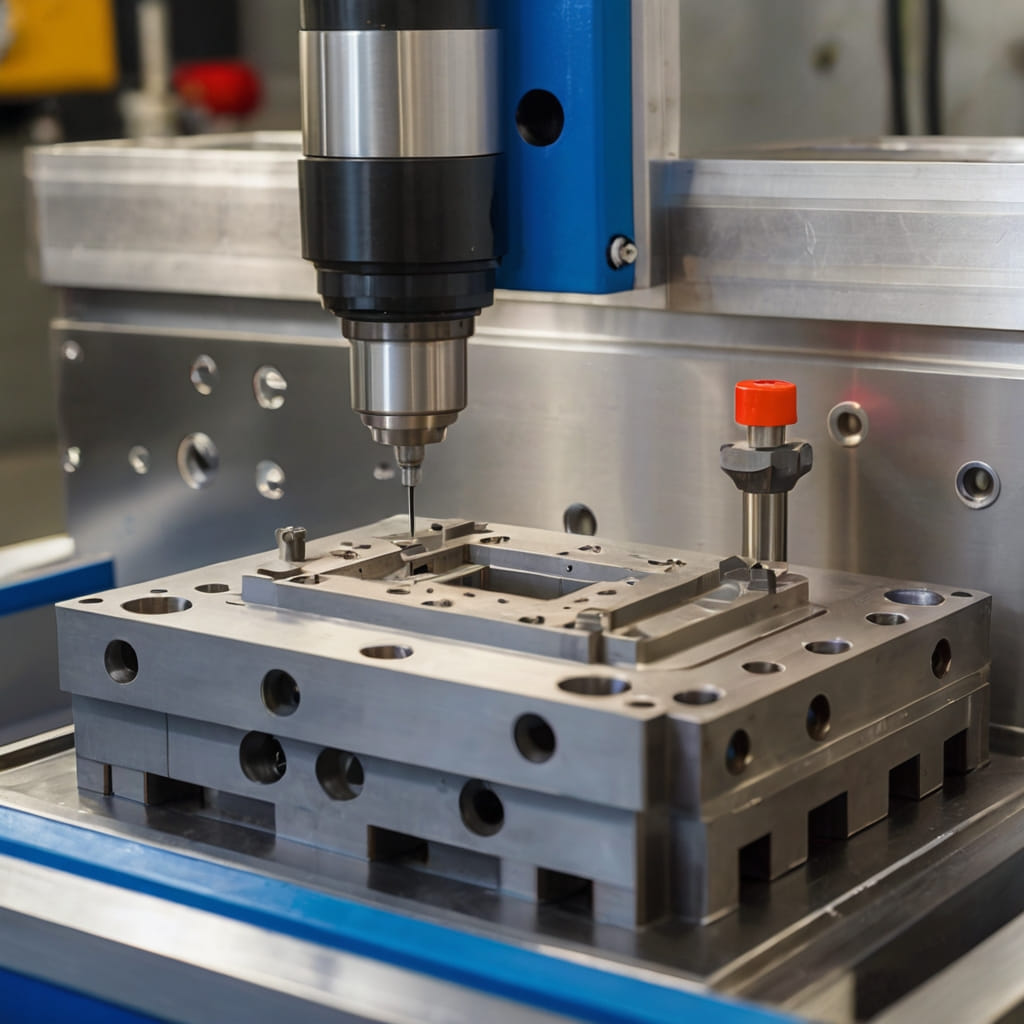

Maquinação CNC

Dispomos de um centro de maquinagem composto por fresagem-torneamento, 3 eixos standard, 5 eixos contínuos, fresadora de 3+2 eixos, perfuração e pós-processamento utilizando mais de 50 metais e plásticos diferentes, disponíveis em mais de 15 acabamentos de superfície. Tolerâncias até ±.0000394" (0.001mm )

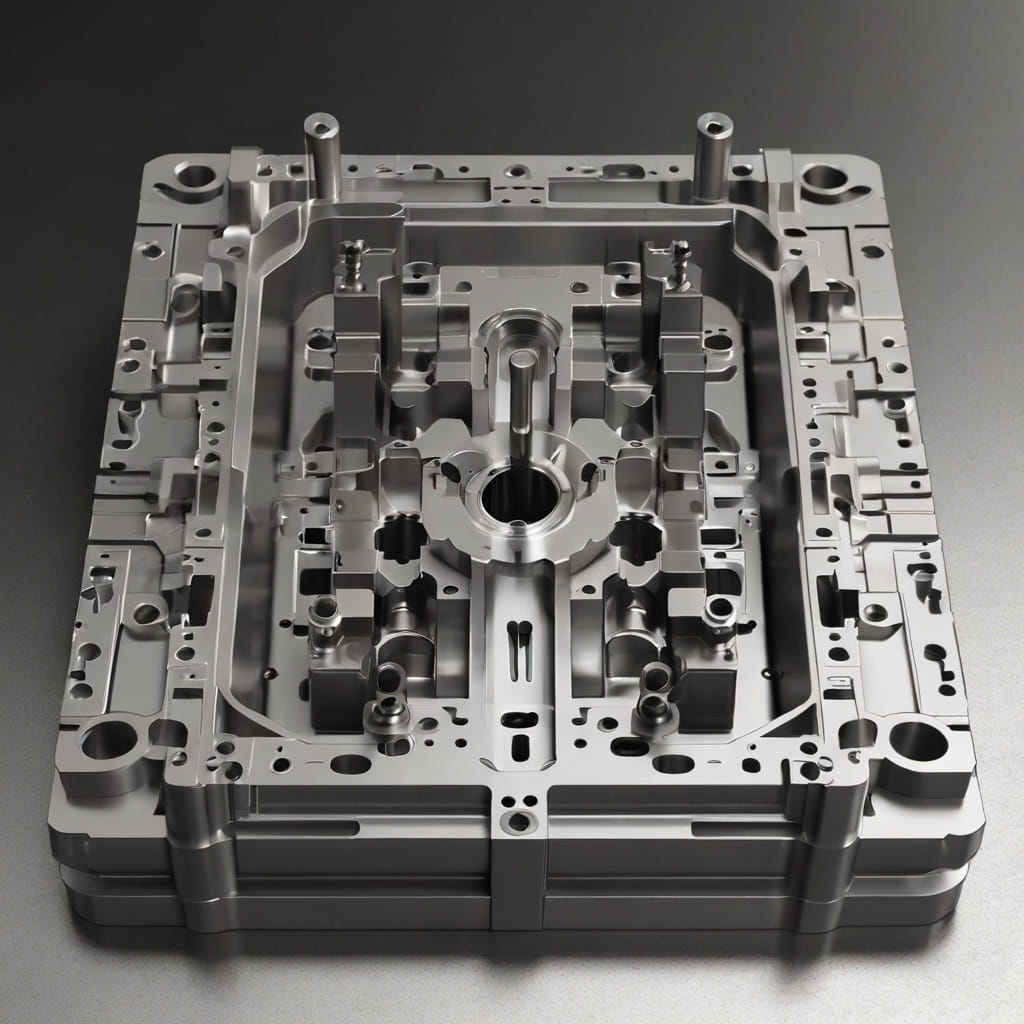

Serviços de moldagem por injeção

A HOFeng pode moldar qualquer termoplástico. Serviços de moldagem por injeção rentáveis para os seus produtos e peças personalizados. Ferramenta de protótipo em apenas 10 dias Ferramenta de produção em apenas 2 semanas, ISO 9001:2015 | Crítico para as inspecções de qualidade

Serviço de impressão 3D

O serviço de impressão 3D da HOFeng é o seu centro de produção de fabricação aditiva para mais de 30 materiais para qualquer aplicação, serviço de impressão 3D Somos especialistas em impressão 3D para atender a todos os seus requisitos de nível industrial.

Serviços de fundição de uretano

A nossa certificação ISO 9001 permite-nos oferecer uma qualidade de topo em cada lote. Somos os especialistas em materiais de poliuretano para o desenvolvimento do seu produto

FAQs sobre moldagem por injeção

Se tem uma moldagem por injeção pronta a começar, estamos aqui para o ajudar do início ao fim. Com a nossa extensa gama de serviços opcionais de pós-processamento e medidas rigorosas de garantia de qualidade implementadas pelo nosso departamento de controlo de qualidade dedicado, pode ter a certeza de que receberá produtos que correspondem às suas expectativas.

Basta enviar-nos os seus ficheiros CAD 3D e a nossa equipa fornecer-lhe-á um orçamento gratuito. Os nossos experientes engenheiros de modelos efectuarão uma análise minuciosa do seu design para efeitos de fabrico (DFM), assegurando que o produto final não só cumpre os seus padrões de qualidade, como também se enquadra nas suas restrições orçamentais.

Com que rapidez posso receber as minhas peças?

As peças de qualidade com menos de 800 unidades podem ser fabricadas no prazo de uma semana se fornecer modelos CAD 2D e 3D completos. As peças mais complexas que exijam outras caraterísticas especiais demorarão mais tempo.

Que considerações devem ser feitas ao conceber peças para maquinagem CNC?

Os projectistas devem considerar factores como o acesso às ferramentas, a seleção de materiais, as tolerâncias e os acabamentos de superfície ao projetar peças para maquinagem CNC.

Quanto tempo demora normalmente um processo de maquinagem CNC?

A duração de um processo de maquinagem CNC depende de factores como a complexidade da peça, o material utilizado e as tolerâncias pretendidas. Pode variar de minutos a horas.

Quais são as certificações ou normas da indústria que cumprem nos vossos processos de maquinagem CNC?

A HOFeng tem certificação ISO 9001 e está em conformidade com a norma ISO 13485.

Quais as tolerâncias que as vossas máquinas CNC conseguem atingir?

As nossas máquinas são capazes de tolerâncias tão apertadas como +/- 0,0002 polegadas.

quanto custa a moldagem por injeção?

O cálculo dos custos de moldagem por injeção envolve múltiplos factores, incluindo a conceção do produto, os custos das matérias-primas, os custos da mão de obra, a depreciação do equipamento, etc.

Conceção do produto: A complexidade, o tamanho, a forma e outros factores afectarão o custo da moldagem por injeção. Alguns produtos complexos podem exigir moldes e técnicas de processamento especiais, e o custo aumentará em conformidade.

Custos das matérias-primas: Os diferentes tipos de matérias-primas plásticas têm preços diferentes e são também afectados por factores como a oferta e a procura no mercado. As matérias-primas representam uma proporção considerável dos custos de moldagem por injeção.

Custo do molde: A moldagem por injeção requer a utilização de moldes especialmente personalizados. Os custos de conceção, fabrico e manutenção do molde afectarão o custo.

Custo de mão de obra: A operação da máquina de moldagem por injeção e o processamento subsequente requerem participação manual. O custo da mão de obra é uma parte do custo da moldagem por injeção que não pode ser ignorada.

Consumo de energia: As máquinas de moldagem por injeção consomem uma grande quantidade de energia, como eletricidade e ar comprimido. Os custos de energia são também uma parte importante dos custos de moldagem por injeção.