石油・ガス産業向けソリューション

- 精密バルブ、ブッシング、センサーとの完璧なマッチングにより、エネルギーインフラの運転効率を向上。

エネルギー精密部品製造サービスをサポート

HOFengは、精密部品の製造と加工で数年の経験を持っています。成熟した工業設計と加工プロセス、様々なCNC工作機械と設備により、精密部品を組み合わせて製造することができます。

エネルギー機器は高精度の付属品に依存している

天然ガス、石油、エネルギー産業は多くのCNC機械加工部品に依存しており、精密バルブ、ブッシング、センサー機器はすべて精密機械加工部品を必要とします。重要なエネルギーインフラの効率的な運用を維持するためには、部品は完璧に調整されている必要があります。過酷な環境で使用される部品は、高精度に加え、高い耐腐食性と耐熱性が要求され、これらの金属は通常、最新のCNC切削工具を必要とします。

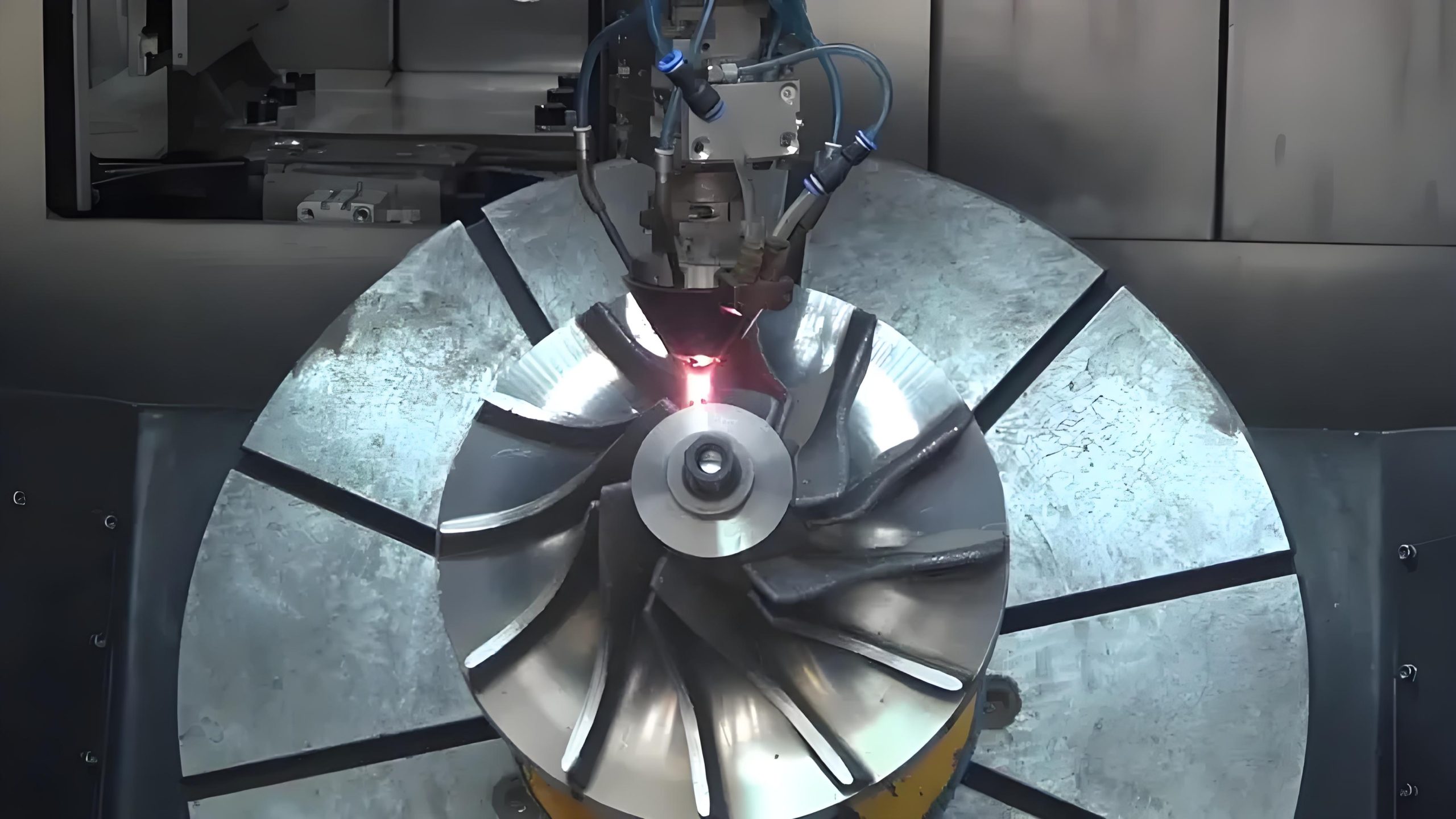

ハイブリッド製造技術

精密部品製造の分野において、HOFengはハイブリッド製造技術を習得し、より精密で高品質な部品をより低コストで迅速に製造することができる。様々な精密部品の製造とそれをサポートする設備の組み合わせにおいて、大きな優位性を持っている。

ハイブリッド製造技術の利点

より精密で高品質な部品をより早く製造できることに加え、ハイブリッド製造技術にはいくつかの利点があります。

- 生産性の向上と生産スピードの加速

- より高い精度と厳しい公差の達成

- 機械性能の向上とコスト削減

- 先行投資と運用コストの削減

- 製造時間を大幅に短縮

ハイブリッド製造技術の欠点

- ハイブリッド製造における高額な初期設備投資

- 混合製造には高いオペレーター要件が必要

HOFengは、既存の設備と熟練したオペレーターを通じて、設計から完成品までの一貫したサービスを提供することで、精密部品の製造を必要とする企業を支援しています。

エネルギー機器用精密部品の製造

その他の製造能力

3Dプリンティング、CNC機械加工、真空鋳造、射出成形、板金加工に特化し、さまざまな素材や表面仕上げを提供しています。

CNC加工

ミルターン複合マシニングセンター、標準3軸、連続5軸、3+2軸フライス盤、ドリル加工、50種類以上の金属とプラスチックを使用した後加工があり、15種類以上の表面仕上げが可能です。公差は±0.0000394"(0.001mm)まで対応。

射出成形サービス

HOFengはあらゆる熱可塑性プラスチックの成形が可能です。カスタム製品や部品のための費用対効果の高い射出成形サービス。プロトタイプ金型は最短10日、生産金型は最短2週間、ISO9001:2015|品質検査の重要性

3Dプリントサービス

HOFengの3D印刷サービスは、あらゆるアプリケーションのための30以上の材料のためのあなたの付加製造業の生産センターである、3D印刷サービス 我々はあなたのすべての要件を満たすために3D印刷の専門家である 工業用グレード。

ウレタン鋳造サービス

部品の急速なプロトタイピングおよび生産のために作ることは、10日、あらゆるpart.Ourのための100%点検のための100%検査証明されるISO 9001はあなたの製品開発の等級質をあらゆるbatch.Weであるポリウレタン材料の専門家届ける