Layanan pencetakan 3d MJF

Membuat prototipe dan produksi suku cadang yang cepat, Suku cadang secepat 10 hari, inspeksi 100% untuk setiap suku cadang

Bersertifikat ISO 9001 kami memberikan kualitas kelas dengan setiap batch

- Tidak ada jumlah pesanan minimum

- Dibuat dengan Cepat dalam Beberapa Menit Hari

- Pembuatan Prototipe Cepat dan Proses Produksi Penuh

- Lebih dari 30+ Bahan Logam dan Plastik Tersedia

Apa itu Pencetakan 3d MJF

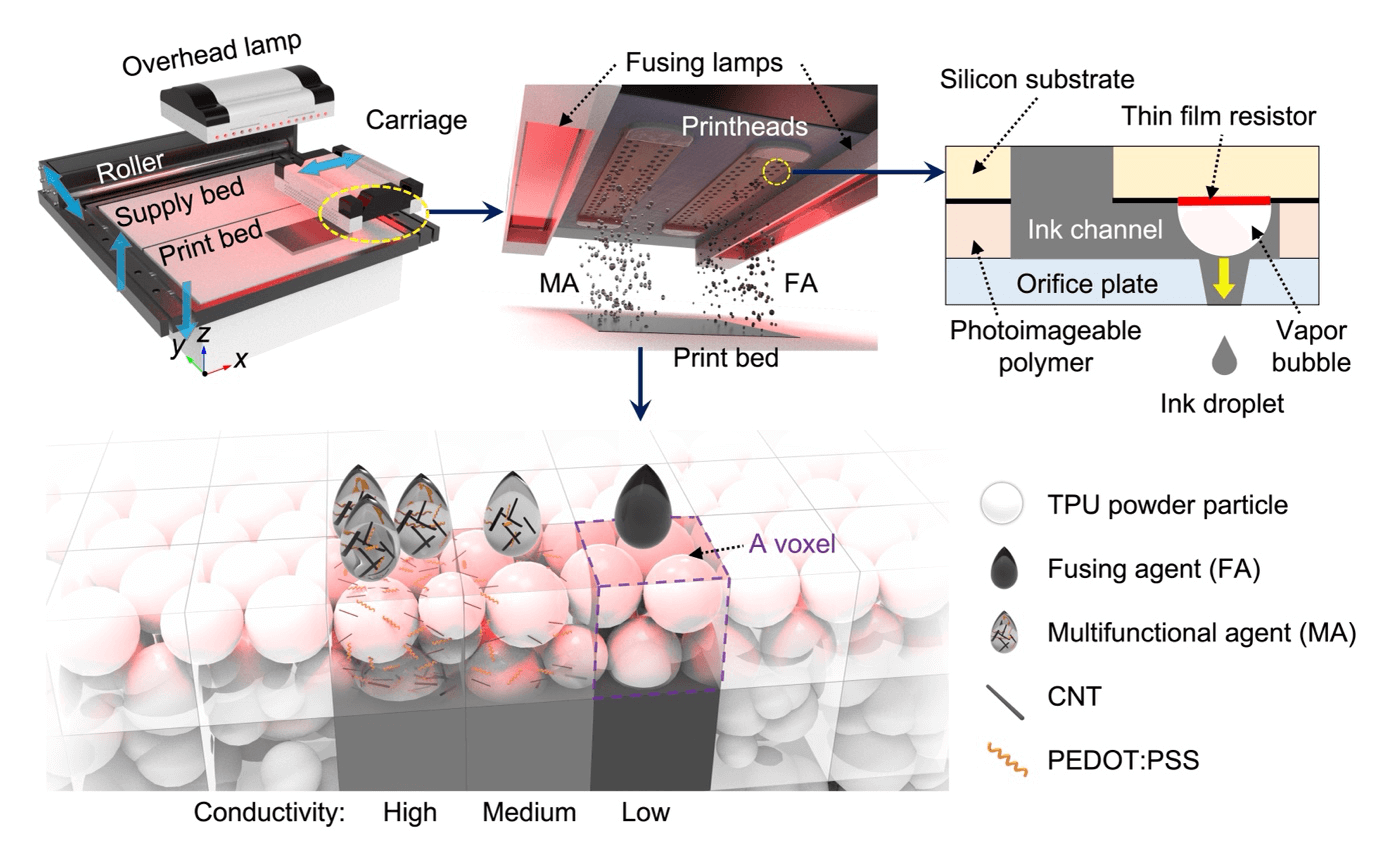

Pencetakan 3D Multi Jet Fusion (MJF) merupakan teknologi manufaktur aditif mutakhir, yang unggul dalam produksi volume tinggi dan presisi. Proses inovatif ini melibatkan pengaplikasian zat peleburan dan zat perincian pada lapisan tipis serbuk, yang dibentuk sesuai dengan penampang bagian yang diinginkan pada ketinggian lapisan tertentu. Sumber panas berikutnya memicu peleburan serbuk, mengubahnya menjadi komponen akhir yang diinginkan.

Setelah setiap siklus fusi, alas cetak turun dengan ketebalan satu lapisan, biasanya berukuran 80 mikron, dan seluruh proses diulangi. Pendekatan lapis demi lapis ini memungkinkan penciptaan geometri yang rumit dan integrasi beberapa bagian dalam satu amplop rakitan, semuanya tanpa memerlukan struktur pendukung. Hal ini tidak hanya merampingkan proses produksi, tetapi juga secara signifikan mengurangi biaya.

MJF digunakan secara luas di berbagai industri, termasuk kedirgantaraan, medis, dan produk konsumen. Keserbagunaannya memungkinkan pencetakan selubung elektronik kedap air, komponen otomotif di bawah kap yang kuat, dan peralatan medis yang dipersonalisasi seperti tungkai palsu dan implan gigi. Kemampuan teknologi ini untuk menangani geometri yang rumit dan menghasilkan banyak bagian secara bersamaan menempatkannya sebagai pengubah permainan di bidang manufaktur aditif.

Mengapa Memilih Pencetakan 3D Multi Jet Fusion

Komponen MJF menunjukkan kepadatan yang sebanding dengan komponen cetakan injeksi plastik, sehingga cocok untuk berbagai aplikasi. Sifat materialnya memungkinkan pemesinan sesuai kebutuhan, memastikan bahwa komponen akhir memenuhi standar kinerja tertentu. Selain itu, komponen ini dapat dibor untuk membuat lubang kecil yang mungkin sulit dibuat selama proses pencetakan.

Apabila kecepatan dan presisi adalah yang terpenting, pencetakan 3D Multi Jet Fusion adalah pilihan yang ideal. Teknologi ini unggul dalam menghasilkan fitur yang sangat detail dan akurat secara dimensi, memastikan bahwa setiap aspek komponen memenuhi spesifikasi yang diinginkan. Printer 3D MJF mampu mencetak fitur yang rumit dengan lebar sesempit 0,1 mm, sehingga cocok untuk desain yang paling rumit sekalipun.

HOFeng menawarkan layanan pasca-pemrosesan ini untuk suku cadang MJF

Proses pencetakan 3D Multi Jet Fusion (MJF) kami menawarkan peningkatan yang luar biasa pada hasil akhir permukaan, secara signifikan mengurangi kekasaran permukaan dari lebih dari 250 μin RA (seperti yang dicetak) ke kisaran 64 - 100 μin RA setelah penghalusan. Pencapaian ini khususnya penting untuk bahan PA12 Black, yang sangat diuntungkan oleh kualitas permukaan yang disempurnakan ini.

Dengan menghaluskan komponen yang dicetak, kami dapat mencapai permukaan akhir berkualitas tinggi yang secara dekat menyaingi penampilan dan kesan komponen yang diproduksi melalui teknik cetakan injeksi.

Pencetakan 3D MJF Mewujudkan proyek Anda.

Pencetakan 3D MJF (Multi Jet Fusion) adalah teknologi manufaktur aditif berkecepatan tinggi dan beresolusi tinggi yang menawarkan berbagai pilihan bahan untuk berbagai proyek. Materialise, penyedia solusi pencetakan 3D terkemuka, menawarkan pilihan bahan yang kompatibel dengan pencetakan MJF, termasuk PA 12 (MJF), PA 12S, PA 11, Ultrasint TPU 90A-01, Nylon 11, dan Nylon 12.

Printer 3D MJF kami

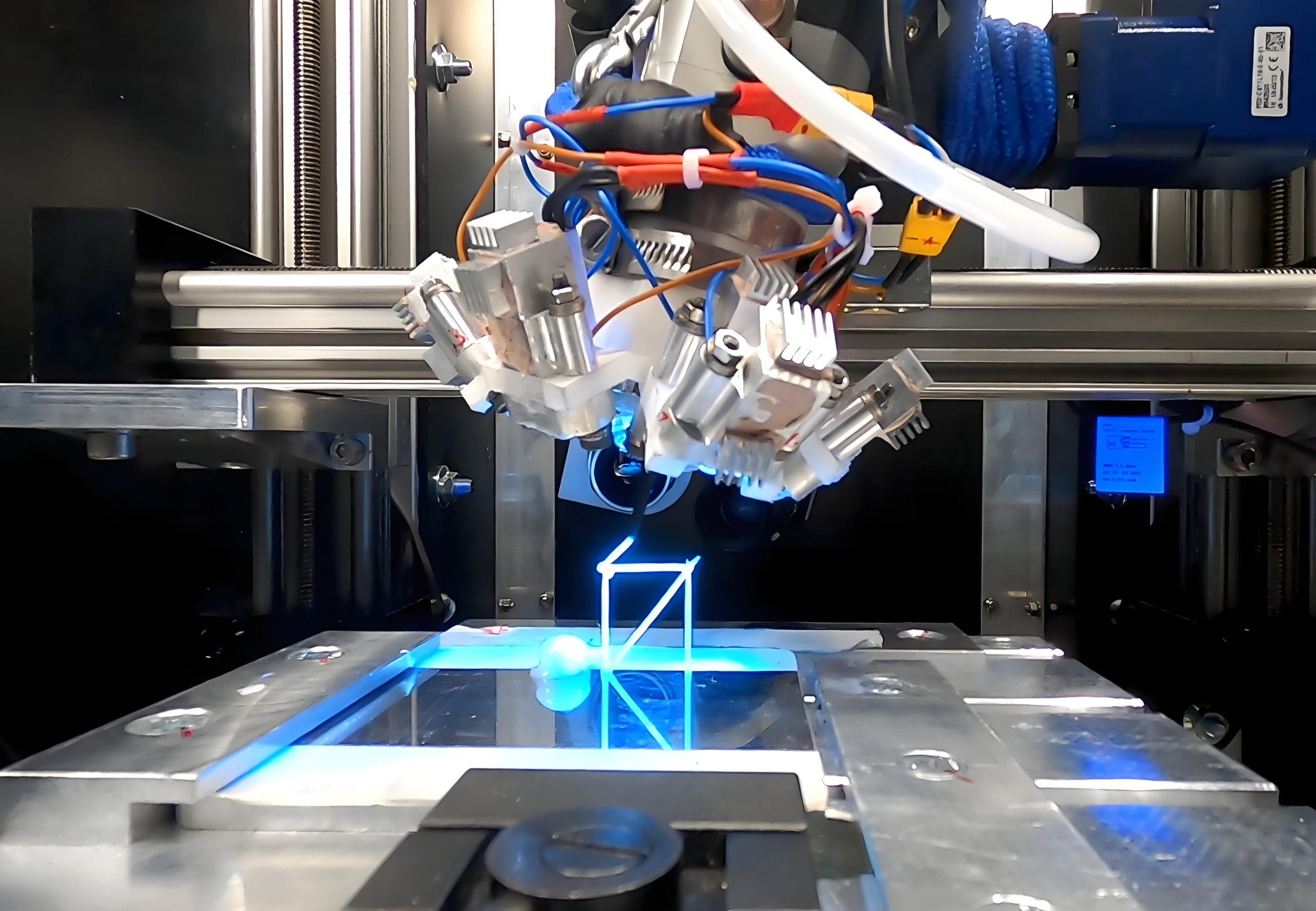

Operasi pencetakan 3D MJF kami didukung oleh mesin HP Jet Fusion 3D 4210 dan 5210, yang menawarkan keunggulan signifikan dalam hal kecepatan pembuatan dibandingkan dengan teknologi manufaktur aditif berbasis bubuk lainnya. Printer ini mampu menghasilkan komponen kelas komersial dengan hasil akhir permukaan yang luar biasa dan sifat mekanis yang unggul, yang membedakannya dari teknologi pencetakan 3D lainnya.

Printer HP Jet Fusion 3D 4210 dan 5210 dirancang untuk produksi bervolume tinggi, memastikan kualitas dan efisiensi yang konsisten di seluruh proses manufaktur. Kecepatan pembuatannya yang dipercepat memungkinkan kami mengirimkan komponen lebih cepat, memenuhi tenggat waktu yang ketat, dan memenuhi permintaan pelanggan. Selain itu, permukaan akhir yang disempurnakan dan sifat mekanis yang lebih baik dari komponen yang dicetak berkontribusi pada daya tahan dan fungsionalitasnya, membuatnya cocok untuk berbagai aplikasi

Berikut ini adalah ikhtisar singkat mengenai fitur dan manfaat utama dari bahan-bahan ini

1. 1. PA 12 (MJF):

Kekuatan dan Daya Tahan Tinggi: PA 12, juga dikenal sebagai nilon 12, menunjukkan sifat mekanis yang sangat baik, sehingga cocok untuk aplikasi yang membutuhkan kekuatan dan daya tahan tinggi.

Ketahanan Kimia yang Baik: Kamera ini menawarkan ketahanan yang baik terhadap berbagai bahan kimia, sehingga cocok untuk digunakan di lingkungan yang keras.

2. PA 12S:

Hasil Akhir Permukaan yang Disempurnakan: PA 12S adalah versi khusus PA 12 yang menawarkan hasil akhir permukaan yang lebih mulus, sehingga ideal untuk aplikasi yang mengutamakan estetika.

Kemampuan Cetak yang Lebih Baik: Properti yang dioptimalkan, juga meningkatkan kemampuan cetak, menghasilkan cetakan yang lebih konsisten dan andal.

3. 3. PA 11:

Fleksibel dan Tangguh: PA 11 adalah bahan nilon semi-kristal yang menawarkan kombinasi fleksibilitas dan ketangguhan, sehingga cocok untuk berbagai aplikasi.

Ketahanan Panas yang sangat baik: Kamera ini dapat menahan suhu yang lebih tinggi tanpa kehilangan bentuk atau sifat mekanisnya.

4. Ultrasint TPU 90A-01:

Elastisitas dan Daya Tahan: Bahan TPU (Thermoplastic Polyurethane) seperti Ultrasint TPU 90A-01 menawarkan elastisitas dan daya tahan yang sangat baik, sehingga cocok untuk aplikasi yang membutuhkan komponen yang fleksibel namun kuat.

Ketahanan Abrasi yang Baik: Bahan TPU juga menunjukkan ketahanan abrasi yang baik, meningkatkan performa jangka panjang komponen cetakan.

5. Nilon 11 dan Nilon 12:

Kekuatan Tarik Tinggi: Baik Nylon 11 dan Nylon 12 menawarkan kekuatan tarik yang tinggi, sehingga cocok untuk aplikasi penahan beban.

Stabilitas Dimensi yang Baik: Stabilitas dimensinya yang istimewa, memastikan cetakan yang akurat dan konsisten, sehingga dapat diandalkan untuk komponen presisi.

Kemampuan Manufaktur Kami yang Lain

Kami Mengkhususkan Diri Dalam Pencetakan 3D, Pemesinan CNC, Pengecoran Vakum, Cetakan Injeksi Dan Fabrikasi Lembaran Logam, Menawarkan Berbagai Macam Bahan Dan Permukaan Akhir.

Mesin CNC

Kami memiliki pusat permesinan komposit Mill-turn, mesin milling 3-sumbu, 5-sumbu kontinu, 3+2 sumbu standar, pengeboran dan pasca-pemrosesan menggunakan lebih dari 50 jenis logam dan plastik yang berbeda, tersedia dalam lebih dari 15 permukaan akhir. Toleransi hingga ±.0000394 "(0.001mm)

Fabrikasi Lembaran Logam

HOFeng dilengkapi dengan pengelasan robot CO2, pemolesan robot, pengelasan laser robot, pengelasan platform laser, mesin pemotong laser, pengelasan laser genggam, mesin punch CNC, mesin bending, mesin deburring otomatis untuk meningkatkan kecepatan dan kemampuan untuk mengatasi aplikasi produksi massal.

Layanan Pengecoran Uretan

Membuat prototipe dan produksi suku cadang yang cepat, Suku cadang secepat 10 hari, inspeksi 100% untuk setiap suku cadang Bersertifikat ISO 9001 kami memberikan kualitas kelas dengan setiap batch Kami adalah ahli bahan poliuretan dalam pengembangan produk Anda