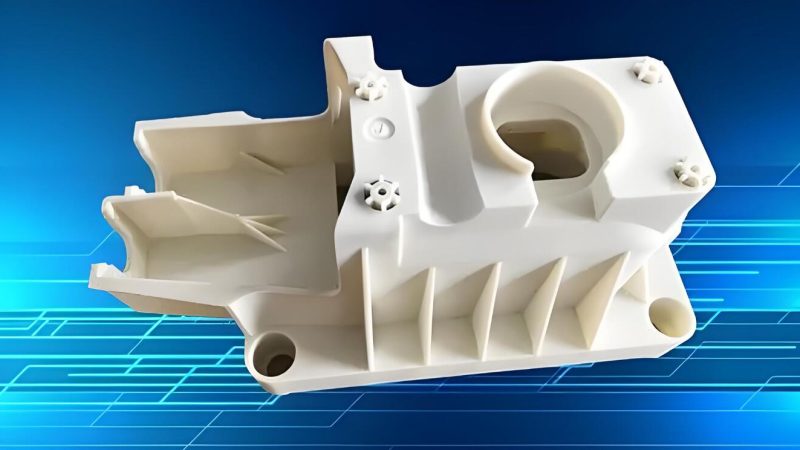

Turn Your Ideas Into High-Quality Products

HOFeng Can Mold Any Thermoplastic.Cost-Effective Injection Molding Services For Your Custom Products And Parts.

Over 15 Years of Experience in Custom Product Manufacturing by following ISO Standards

- Prototype Tool In Soon As 10 Days

- Production Tool In As Soon As 2 Weeks

- ISO 9001:2015 | Critical To Quality Inspections

- Please Reach Out With Your Specific Resin Needs.

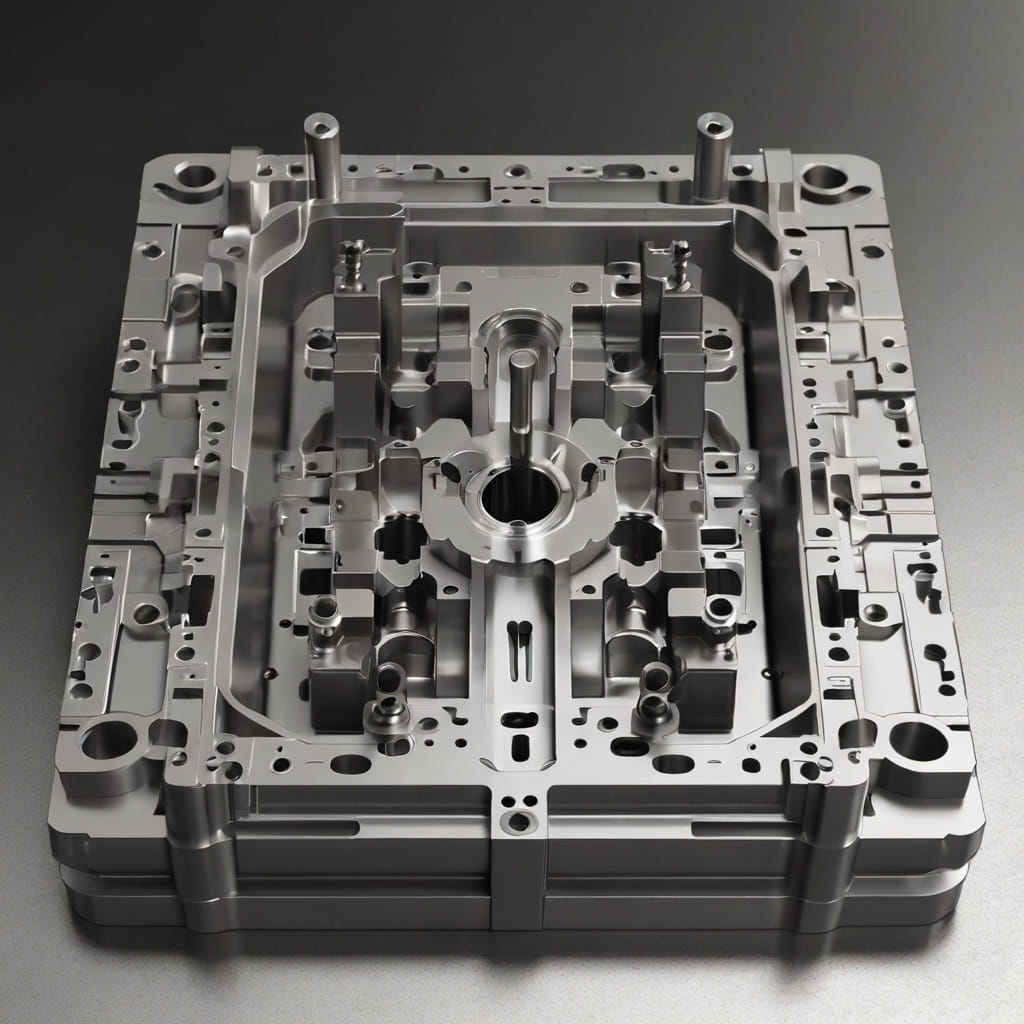

what is injection molding?

Injection molding is a molding method that combines injection and molding, also known as injection molding. The general injection molding method is to place polymer component granules or powders into the barrel of an injection molding machine, where they undergo heating, compression, shearing, mixing, and conveying processes. Then, with the help of a plunger or screw, pressure is applied to the melted polymer melt. The high temperature melt is then injected into a pre-closed low temperature mold cavity through the nozzle in front of the barrel and the mold's gating system. After cooling and solidifying, the mold can be opened, the product can be ejected, and plastic products with certain geometric shapes and precision can be obtained.Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today.

Injection molding applications

Plastic injection parts have high output and wide application. This is because plastic parts have some practical value compared to metal parts. Plastics are widely used as engineering structural components, such as housings, frames, and bases for electronic instruments, automotive, household appliances, and communication equipment are used to protect, enhance and build a huge range of products. The process is known for its capabilities for speed, precision, and efficiency and has become one of the most popular manufacturing services for the production of plastic parts.

Post-Processing & Finishing Options

Surface treatment in injection molding refers to the process of applying a specific treatment or coating to the surface of a machined part, such as painting or hot-swap inserts.

Inserts.Pad Printing.Painting.Silk screening.Ultrasonic welding.Laser engraving.UV coating.Heat staking.Hot stamping.Post-mold machining

Plastic injection Molding Capabilities

Our Injection molding machine:

High speed injection molding machine

PVC special injection molding machine

PET special injection molding machine

Double Color Injection Molding Machine

We are capable of preserving a machining allowance of +/- 0.003 inches (0.08mm), while also incorporating a resin tolerance that falls within a range greater than, yet never less than, +/- 0.002 inches per inch (0.002mm per mm).

To address this issue, we utilize advanced machining techniques and precision equipment to ensure that our tolerances are met with utmost accuracy. The +/- 0.003 inch (0.08mm) machining tolerance ensures that the finished product meets the required specifications, while the included resin tolerance of +/- 0.002 inches per inch (0.002mm per mm) allows for a degree of flexibility in the material itself.

By maintaining these tight tolerances, we are able to deliver high-quality products that meet the demands of our customers. Whether it's for industrial applications or precision manufacturing, We strive to exceed expectations and deliver exceptional results.

Plastic Injection Molding Materials

Property:

lmpact resistant

Wear-resistant

Dimensional stability

Chemical resistance

Rubber like

Cost-efficient

Cosmetic

Materials:

ABS,PMMA, PVC,PE, PC

POM, PEEK, UHMW

ABS,PBT, HIPS,PPS

PEEK, PP, PBT, PE, LDPE, PA

TPU, TPE, Silicone

PP, HDPE, LDPE

ABS,PC,HIPS

Maximum Dimensions:

Size:480mm x 751mm

Volume:966.837 cu.mm

Depth:101mm from parting line

Projected Mold Area:112,903 sq. mm

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

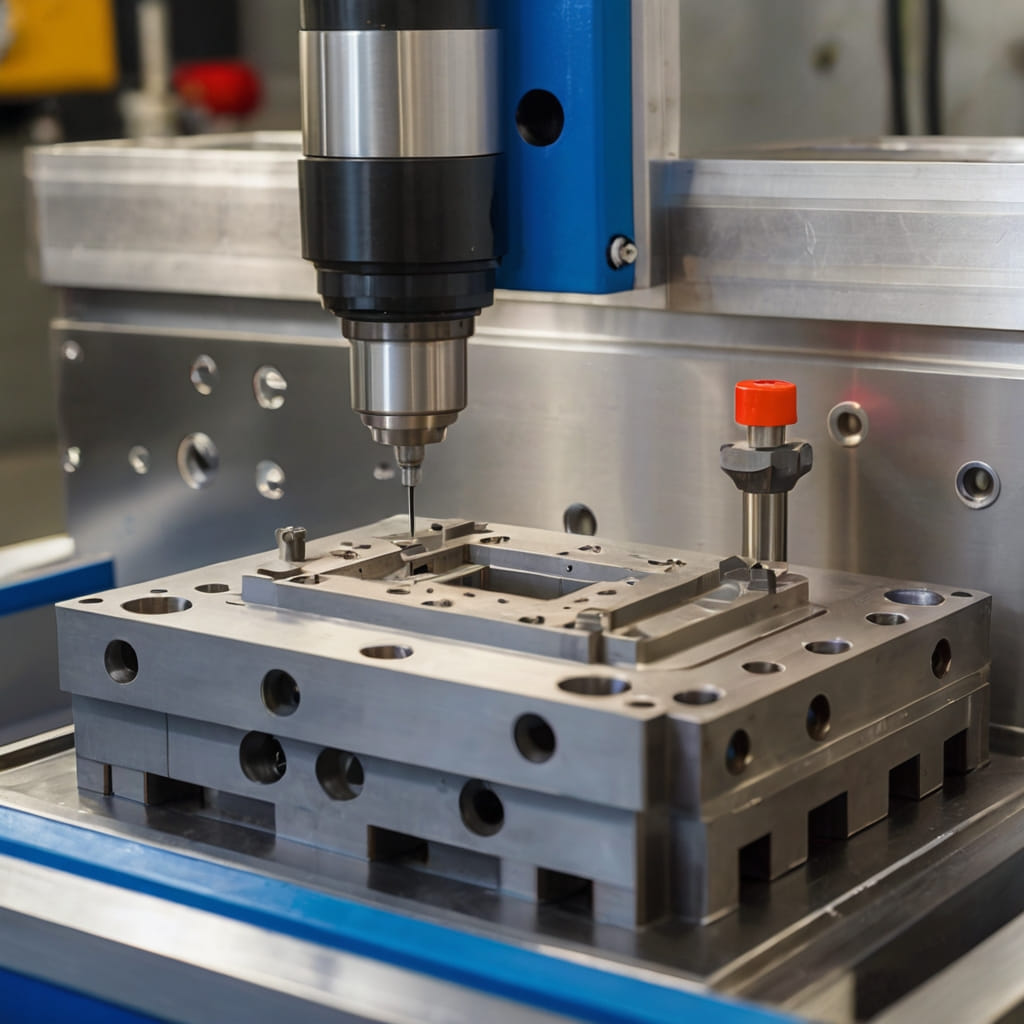

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development

Injection Molding FAQs

If you have aInjection Molding ready to commence, we are here to assist you from start to finish. With our extensive range of optional post-processing services and rigorous quality assurance measures implemented by our dedicated QC department, you can rest assured that you will receive products that meet your expectations.

Simply send us your 3D CAD files, and our team will provide you with a free quote. Our experienced model engineers will perform a thorough design for manufacturability (DFM) analysis on your design, ensuring that the final product not only meets your quality standards but also fits within your budget constraints.

How quickly can I get my parts?

Quality parts less than 800pcs can be made in as fast as one week if you provide complete 2D and 3D CAD models. More complex parts requiring other special features will take longer.

What considerations should be made when designing parts for CNC machining?

Designers should consider factors such as tool access, material selection, tolerances, and surface finishes when designing parts for CNC machining.

How long does a CNC machining process typically take?

The duration of a CNC machining process depends on factors such as the complexity of the part, the material being used, and the desired tolerances. It can range from minutes to hours.

What certifications or industry standards do you adhere to in your CNC machining processes?

HOFeng is ISO 9001 certified, ISO 13485 compliant.

What tolerances can your CNC machines achieve?

Our machines are capable of tolerances as tight as +/- 0.0002 inches.

how much does injection molding cost?

The calculation of injection molding costs involves multiple factors, including product design, raw material costs, labor costs, equipment depreciation, etc.

Product design: Complexity, size, shape and other factors will affect the cost of injection molding. Some complex products may require special molds and processing techniques, and the cost will increase accordingly.

Raw material costs: Different types of plastic raw materials have different prices, and are also affected by factors such as market supply and demand. Raw materials account for a considerable proportion of injection molding costs.

Mold cost: Injection molding requires the use of specially customized molds. The design, manufacturing and maintenance costs of the mold will affect the cost.

Labor cost: Operating the injection molding machine and subsequent processing requires manual participation. Labor cost is a part of the injection molding cost that cannot be ignored.

Energy consumption: Injection molding machines consume a large amount of energy such as electricity and compressed air. Energy costs are also an important part of injection molding costs.