전기 자동차 제조 및 솔루션

- 외장 부품, 맞춤형 기어 솔루션 등 자동차에 사용되는 다양한 부품들

전기 자동차 부품 가공 및 기어 제조 서비스

HOFeng은 수년 동안 자동차 부품 분야에 깊이 관여해 왔으며 포괄적인 설계, 가공 및 조립 능력을 갖추고 있습니다. '원스톱' 서비스를 제공하고 전기 자동차 제조 기업 고객에게 최고의 솔루션을 제공할 수 있습니다.

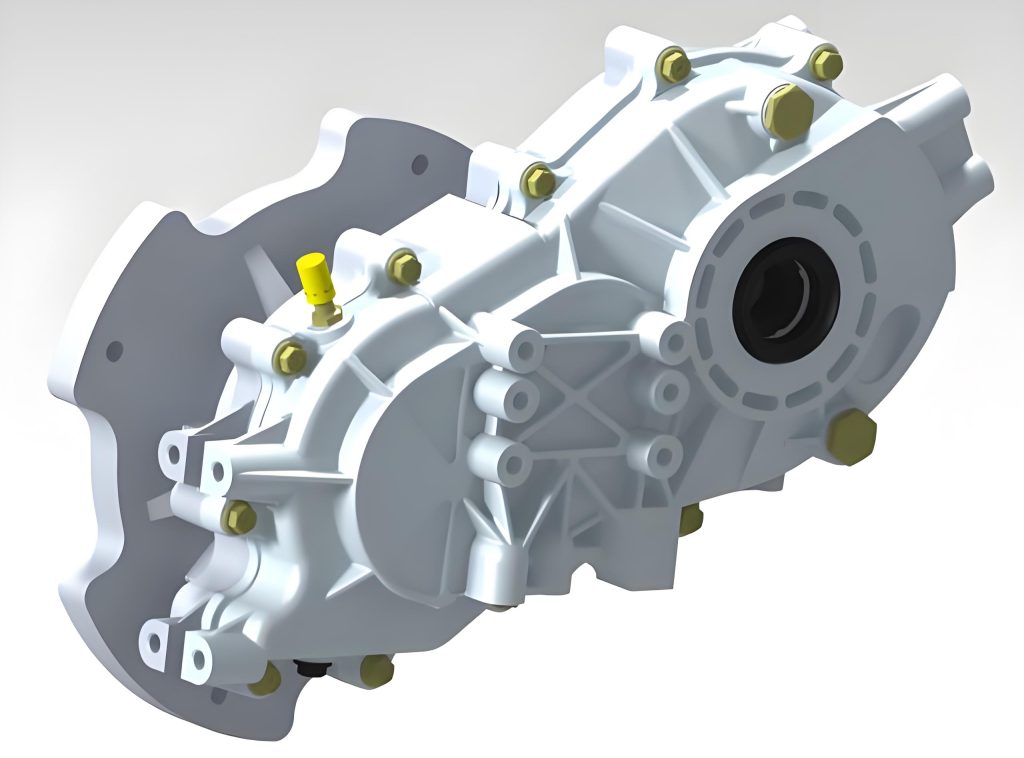

전기 자동차 부품의 맞춤형 가공

HOFeng은 자동차 부품의 맞춤형 가공을위한 완벽한 산업 프로세스를 보유하고 있습니다. 기존 자동차이든 전기 자동차이든 자동차 부품의 맞춤화 및 가공은 매우 성숙하고 고객의 다양한 요구를 해결할 수있는 능력을 갖추고 있습니다.

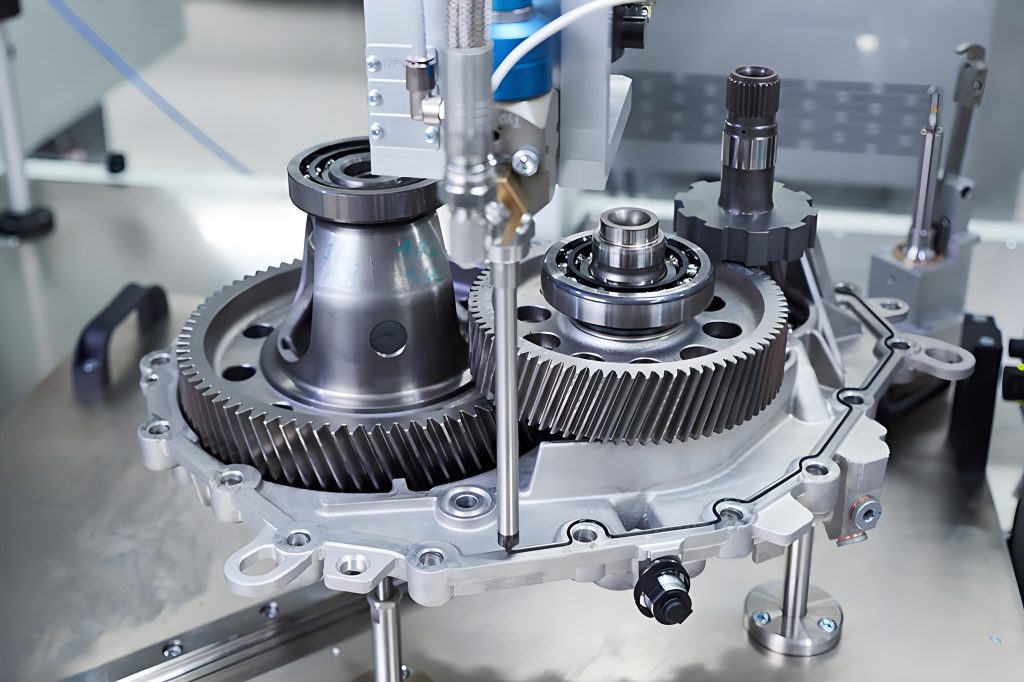

기어박스 기어의 커스터마이징 및 가공

전기차는 변속기 기어에 대한 요구 사항이 더 높습니다. 가솔린 차량의 변속기에 비해 유성 변속기는 더 작고 가벼우며, 그에 따라 기어 가공에 대한 요구 사항도 더 높습니다.

HOFeng은 다양한 기어의 가공을 처리하기 위해 완벽한 CNC 산업 제조 시스템을 사용합니다.

전기 자동차 변속기를 위한 맞춤형 기어의 장점

- 모터의 소음을 줄일 수 있습니다;

- 클러치는 토크 댐핑을 제공할 수 있습니다;

- 모터의 고효율 범위를 확장할 수 있습니다;

- 차량 전체를 더욱 강력하게 만드세요;

- 모터의 요구 사항을 줄일 수 있습니다.

설계 및 개발 역량

서비스

기타 제조 역량

당사는 3D 프린팅, CNC 가공, 진공 주조, 사출 성형 및 판금 제작을 전문으로 하며 다양한 재료와 표면 마감을 제공합니다.

CNC 가공

당사는 밀턴 복합 머시닝 센터, 표준 3축, 연속 5축, 3+2축 밀링 머신, 50개 이상의 다양한 금속 및 플라스틱을 사용한 드릴링 및 후가공을 15개 이상의 표면 마감으로 제공하고 있습니다. 공차 ±.0000394"(0.001mm )

사출 성형 서비스

HOFeng은 모든 열가소성 플라스틱을 성형할 수 있습니다. 맞춤형 제품 및 부품을위한 비용 효율적인 사출 성형 서비스. 빠르면 10 일 안에 프로토 타입 도구 빠르면 2 주 안에 생산 도구, ISO 9001 : 2015 | 품질 검사에 중요

3D 프린팅 서비스

HOFeng의 3D 프린팅 서비스는 모든 애플리케이션을위한 30 개 이상의 재료, 3D 프린팅 서비스를위한 적층 제조 생산 센터입니다. 우리는 모든 요구 사항을 충족하는 3D 프린팅 전문가입니다 산업 등급.

우레탄 주조 서비스

부품의 신속한 프로토 타이핑 및 생산을위한 제작, 10 일의 빠른 부품, 모든 부품에 대한 100% 검사, ISO 9001 인증은 모든 배치에 등급 품질을 제공합니다. 우리는 제품 개발의 폴리 우레탄 소재 전문가입니다.