NEMA 12エンクロージャ&ボックス

厳しい屋内産業環境向けに設計されたHofengfabのNEMA 12エンクロージャは、ほこり、落下する汚れ、滴下する液体、および軽度の水しぶきに対する認定保護を提供します。産業用エンクロージャの製造で15年以上の経験を持つ当社は、信頼性の高い保護、迅速なリードタイム、競争力のある価格に対するお客様のニーズを理解しています。NEMAタイプ12エンクロージャは、プラスチック、アルミニウム、スチール製で、便利なスタイルとサイズを取り揃えています。HofengfabのすべてのNEMAエンクロージャは、ULによる試験と認証を受けており、保護が保証されています。

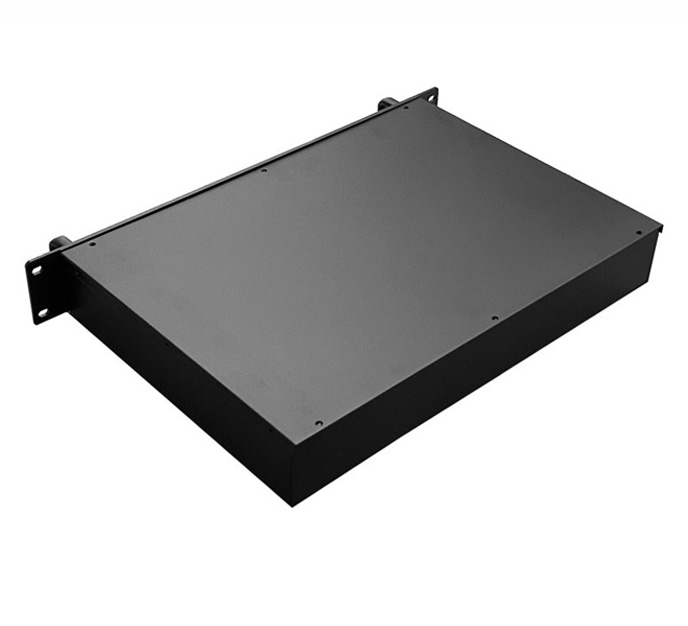

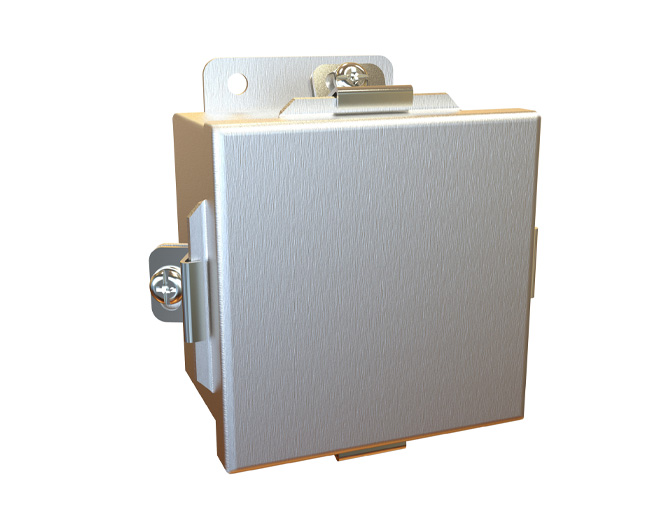

NEMA 12エンクロージャ

Hofengfabは少量多品種のオーダーメイドソリューションを専門としており、高さ、幅、奥行き、素材、定格、認証など、お客様の仕様に合わせた1,600以上のカスタマイズ可能なオプションを提供しています。7~10営業日でサンプルをご用意し、15~25営業日で大量生産を完了するなど、迅速な納期をお約束します。小ロットでも大量注文でも、納期厳守でお届けします。

利用可能なサイズと構成

小型の壁掛けボックスから大型の床置きキャビネットまで、お客様の仕様に合ったNEMA 12エンクロージャを各種取り揃えています。からお選びください:

ヒンジ式またはスクリュー式カバー

バックパネルとスイングパネル

床または壁取り付けキット

食品用ステンレススチール

特徴と仕様

| 保護レベル | 建設 | コンプライアンスと認証 |

| ✔️ NEMA 12定格(防塵、防滴) | ✔️ 頑丈な16ゲージ・スチール | ✔️ NEMA 250およびUL 50認定 |

| ✔️ ホコリ、繊維、クーラントの循環に耐える。 | ✔️ 粉体塗装仕上げ(標準) | ✔️ CE、RoHS対応 |

| ✔️ 軽度のオイル/クーラントの飛散を防ぐ | ✔️ 継ぎ目を溶接して完全性を確保 | ✔️ IP54相当の保護等級 |

| 屋外/水没用ではありません。 | ✔️ オプションのステンレススチール | 防水ではない (NEMA 4X/6P を使用) |

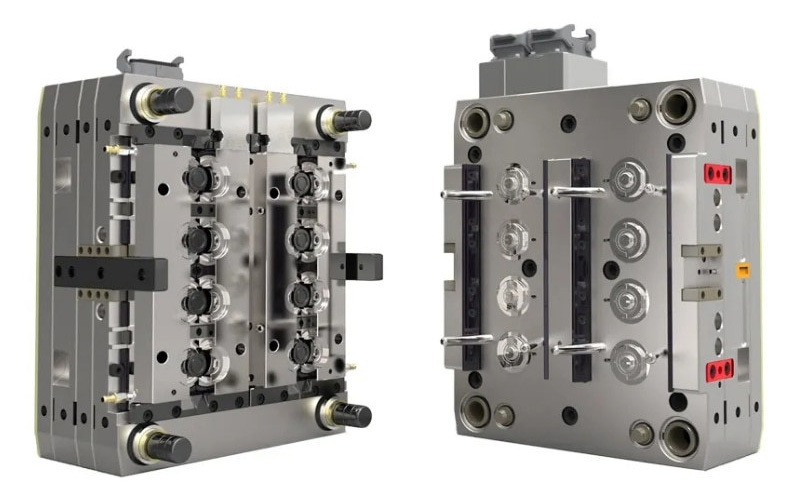

設計、成形、射出成形のワンストップサービス。

カスタム製作サービス

曲げ加工、レーザー切断、ブラシ溶接、研磨、プレスなどの精密板金加工を専門とする。

オンタイム・デリバリー。

プロトタイピングは通常10日以内に完了する。

標準的な生産リードタイムは、製品の数量や複雑さにもよりますが、約15日です。

よくあるご質問

NEMA 12エンクロージャーとは何ですか?

A NEMA 12エンクロージャー は、次のような目的で設計された電気筐体の一種です。 室内使用 産業環境におけるこれは ほこり、ほこり、糸くず、繊維、非腐食性の液体の滴下.これらのエンクロージャは、制御盤、リレー、その他の繊細な電気・電子部品を収納するために一般的に使用されます。

NEMA 12エンクロージャーとNEMA 4エンクロージャーの違いは何ですか?

重要な違いは次の点にある。 ウォータープロテクション:

NEMA 12:ホコリや水滴を防ぐ。 屋内、乾燥した環境.

NEMA 4:からの保護 ホース導水 そして 時折水没使用可能 屋外 または洗い場で。

水しぶきや屋外暴露を伴う用途の場合は、NEMA 4を選択するのがよい。

NEMA 12エンクロージャーは防水ですか?

いや。 NEMA 12エンクロージャは防水ではありません。.に強い。 軽い水滴または水しぶき しかし 高圧水用に設計されていない または完全な水没。防水性能については、NEMA 4または6エンクロージャをご検討ください。

NEMA 12エンクロージャは通常どこで使用されますか?

広く使われている:

製造工場

倉庫

データセンター

食品加工(ドライエリア)

HVACシステム制御室

CNCマシンパネル

産業オートメーションとロボット工学

NEMA 12エンクロージャはUL規格に適合していますか?

はい、ほとんどの高品質NEMA 12エンクロージャは ULリストおよびCSA認証認証は、厳格な安全基準と性能基準を満たしていることを保証するものです。ご購入の際は、必ず認定をご確認ください。

NEMA 12エンクロージャは屋外で使用できますか?

いや。 NEMA 12は屋内専用.屋外環境では NEMA 3R、4、または4X 風雨、洗浄、腐食性物質への暴露によっ ては、エンクロージャが変化する。

NEMA 12エンクロージャはどのような材料で作られていますか?

一般的な素材は以下の通り:

カーボンスチール(粉体塗装) - 一般産業用として最も広く使用されている。

ステンレススチール(304または316) - 衛生面や耐食性が要求される環境で使用される。

アルミニウムまたはポリカーボネート - 一般的ではないが、軽量または特殊な用途に使用可能。

カスタムNEMA12エンクロージャーはありますか?

はい。多くのメーカーが カスタマイズ可能なオプション を含む:

サイズと取り付け

カットアウトとノックアウト

塗装仕上げ

ドアの種類(ヒンジ、両開き、ロック機構)

内部取付けパネルまたはDINレール