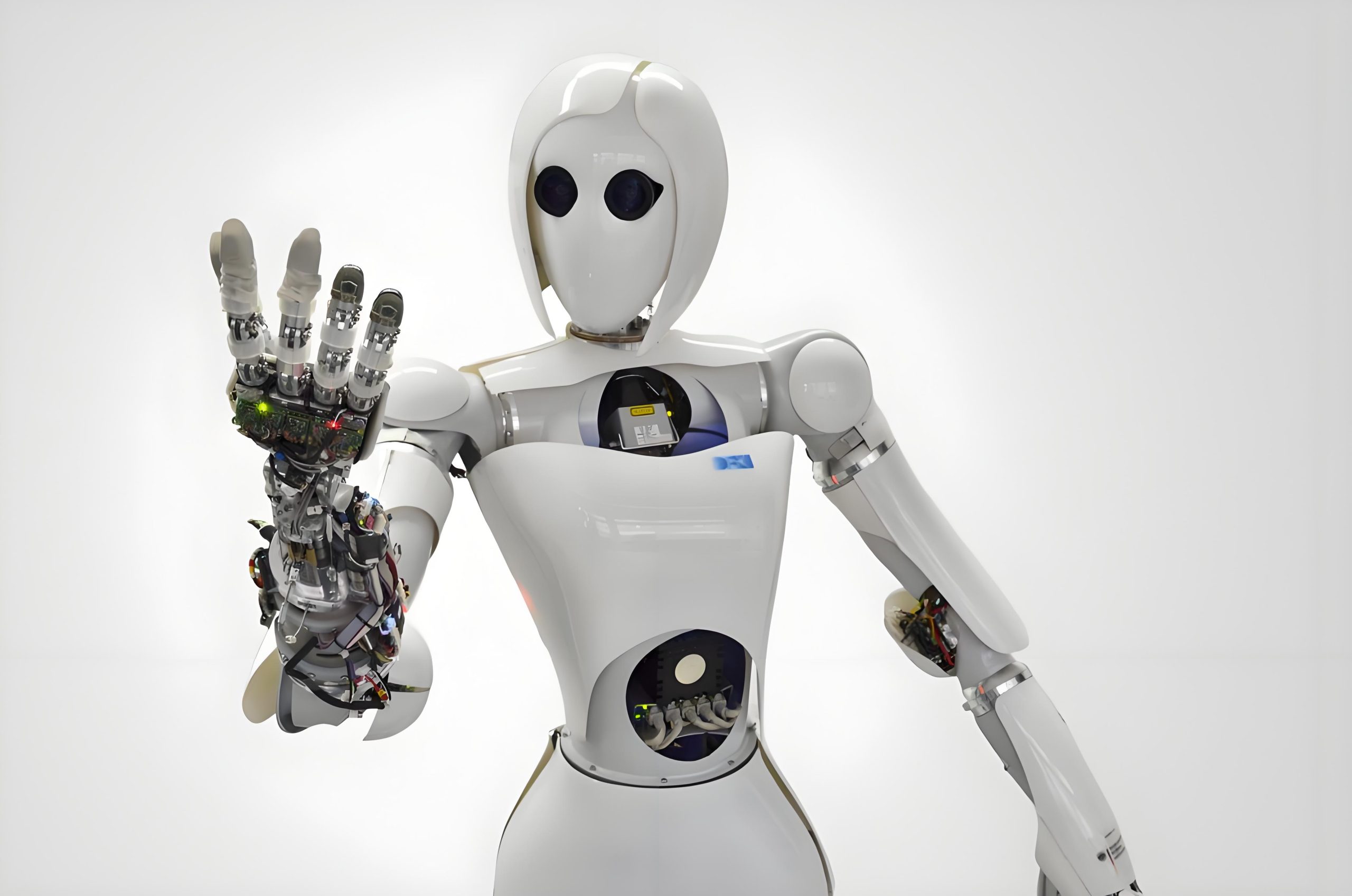

HOFengは長年のCNC機械加工の経験に基づいて、ロボット部品の設計と加工に深い基礎を持っており、部品の強度と精度を確保するために、大量の部品加工を完了することができます。

ロボットの部品設計と製造の統合は、製造された部品が製品設計の精度とより一致することを保証することができ、部品製造と組立にもっと貢献する。

HOFengは、CNC機械加工の分野で経験を持っており、製品設計から完成品の生産、最終的な組み立てに至るまで、工業生産プロセスの完全なセットを持っています。成熟した業界プロジェクトの経験を持ち、カスタマイズされた部品の生産に対する顧客のニーズを最大限に満たすことができる。

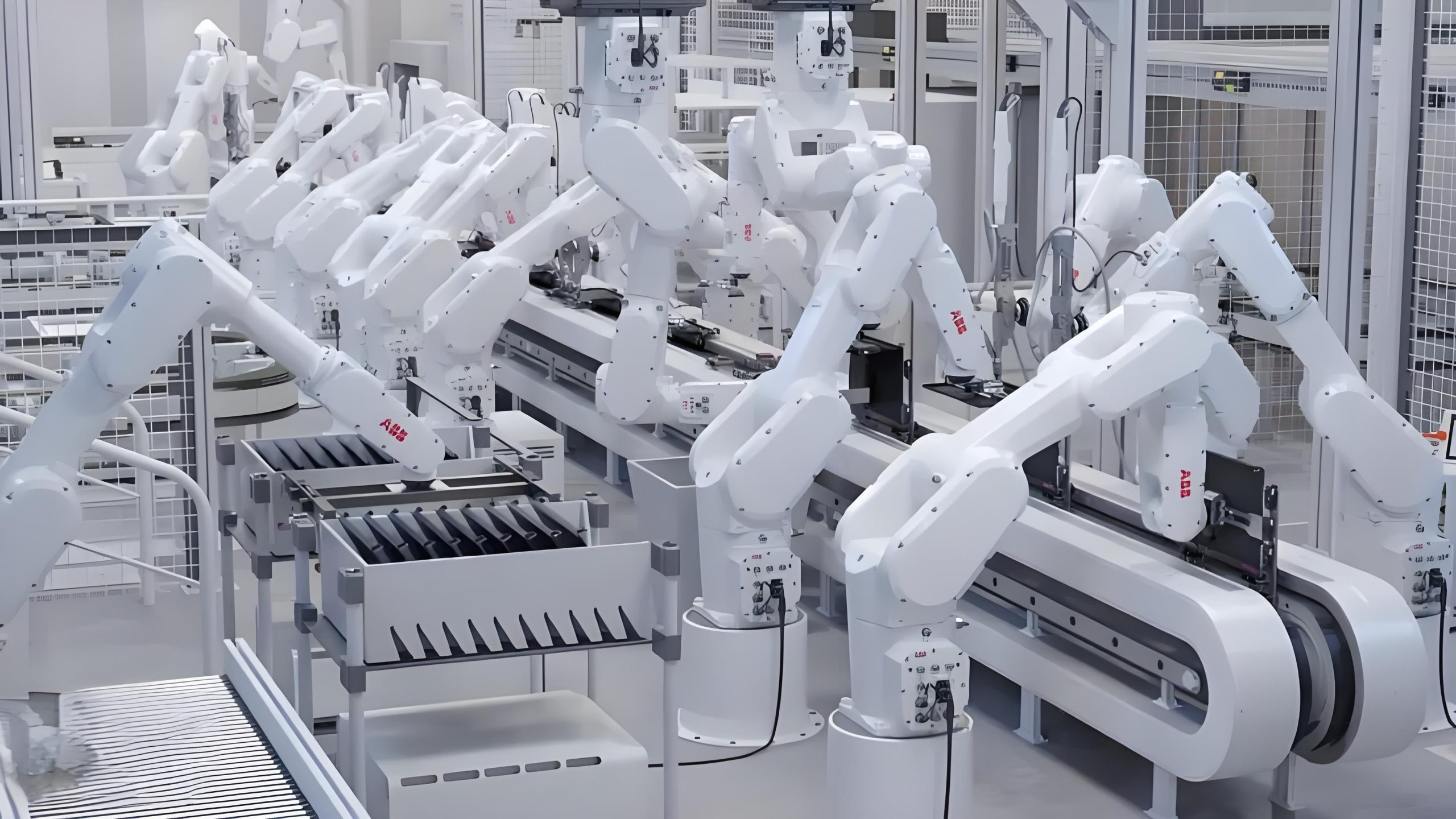

CNC工作機械の助けを借りて、相互作用は、プログラミング命令、センサーフィードバック、およびロボットの動き、アクション、タスクを制御するための他の方法を介して達成され、自動化された操作と生産制御を実現します。製造業では、生産効率、精度、一貫性を向上させ、ヒューマンエラーを減らし、生産コストを下げ、複雑な部品加工などの利点を実現し、生産工程をよりインテリジェントにし、生産効率を向上させることができる。

産業インテリジェンスの発展に伴い、CNC技術とロボットは共に急速に進歩している。UoAoロボットのように、その応用場面はますます広範かつ複雑になっている。それに応じて、CNC技術もますます複雑化・成熟化し、より多くの課題に適応し、より効率的で精密かつ柔軟な生産方式を人間に提供するようになるだろう。

3Dプリンティング、CNC機械加工、真空鋳造、射出成形、板金加工に特化し、さまざまな素材や表面仕上げを提供しています。

ミルターン複合マシニングセンター、標準3軸、連続5軸、3+2軸フライス盤、ドリル加工、50種類以上の金属とプラスチックを使用した後加工があり、15種類以上の表面仕上げが可能です。公差は±0.0000394"(0.001mm)まで対応。

HOFengはあらゆる熱可塑性プラスチックの成形が可能です。カスタム製品や部品のための費用対効果の高い射出成形サービス。プロトタイプ金型は最短10日、生産金型は最短2週間、ISO9001:2015|品質検査の重要性

HOFengの3D印刷サービスは、あらゆるアプリケーションのための30以上の材料のためのあなたの付加製造業の生産センターである、3D印刷サービス 我々はあなたのすべての要件を満たすために3D印刷の専門家である 工業用グレード。

部品の急速なプロトタイピングおよび生産のために作ることは、10日、あらゆるpart.Ourのための100%点検のための100%検査証明されるISO 9001はあなたの製品開発の等級質をあらゆるbatch.Weであるポリウレタン材料の専門家届ける