医療機器ソリューションのための板金加工

-

医療機器ソリューションのための板金加工。

医療用板金部品のニーズはHOFengにお任せください。

私達は深い経験および歴史があり、私達の内部特徴の許容は ±0.001 "に維持されます。

外部特性公差は±0.003 "に保たれ、0.003 "という薄い金属材料も使用できる。

医療機器ソリューションのための板金加工

医療機器自体、「多品種・小ロット」という特性があり、板金構造部品には特殊な加工が要求される。

板金部品

医療機器の主構造における板金部品は、主に耐荷重部品、連結部品、外枠、補助キャビネット(電源キャビネットなど)に分けられる。これらの構造部品のうち、主に中厚板でできている連結部品以外は、ほとんどが薄板である。材質は主にステンレス鋼板とアルミニウム板で、一部アルミニウム-亜鉛めっき鋼板と冷間圧延鋼板がある。

世界をリードする品質

可動連結部品、特に溶接後の連結部品の精度要求は、アプリケーションソフトの要求に従って調整し、一貫して実行する必要があります。外枠の表面外観プロセス要件、不規則な外観の形成、欠陥のない表面、一貫した溶接と研磨。

中国板金加工工場

プロトタイプ工場では、コンセプトカー、テストカー、設計プロセスの全段階におけるプロトタイプのほか、高度にカスタマイズされた少量生産の完成車や部品を生産しています。高度な設備技術と経験豊富な従業員により、医療機器に要求される厳格な公差と精密な寸法を持つカスタムプレス金属部品や板金製造が可能です。当社の内部特性公差は±0.001"、外部特性公差は±0.003 "に保たれており、0.003 "という薄い金属材料も使用可能です。私たちは、最初の部品から最後の部品まで優れた再現性を持つ小から中バッチのプレス部品と機械加工部品を提供します。当社の専門チームは、医療機器用の多種多様な板金部品を生産することができます。

設計・開発能力

すべての部品が顧客の設計要件と当社の品質基準を満たすことを確実にするため、当社は中国広東省の施設内に完全な金型ワークショップを有しており、社内の金型製造能力により、完成した金型が当社の拠点に届くのを待つ必要がなくなり、生産速度が向上した。

製造および試験能力

その他の製造能力

3Dプリンティング、CNC機械加工、真空鋳造、射出成形、板金加工に特化し、さまざまな素材や表面仕上げを提供しています。

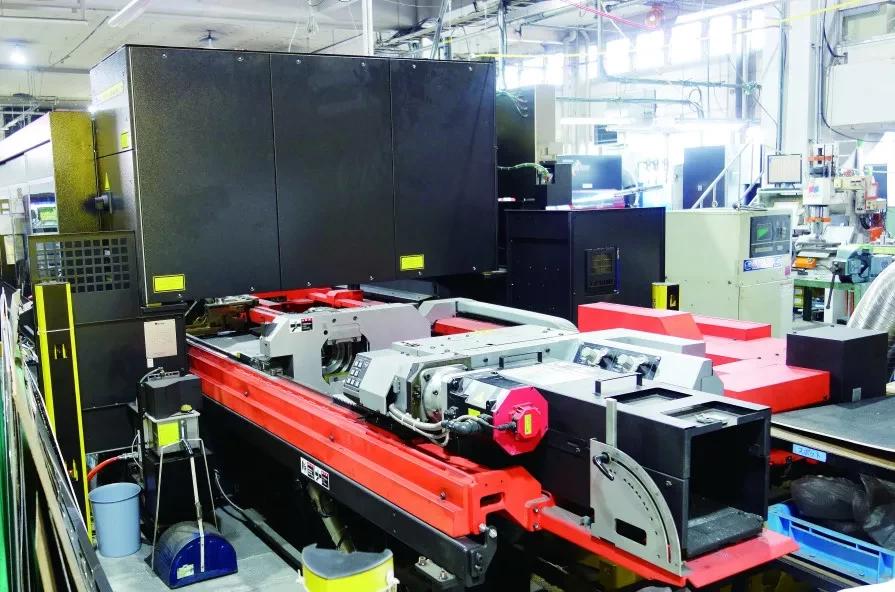

CNC加工

ミルターン複合マシニングセンター、標準3軸、連続5軸、3+2軸フライス盤、ドリル加工、50種類以上の金属とプラスチックを使用した後加工があり、15種類以上の表面仕上げが可能です。公差は±0.0000394"(0.001mm)まで対応。

射出成形サービス

HOFengはあらゆる熱可塑性プラスチックの成形が可能です。カスタム製品や部品のための費用対効果の高い射出成形サービス。プロトタイプ金型は最短10日、生産金型は最短2週間、ISO9001:2015|品質検査の重要性

3Dプリントサービス

HOFengの3D印刷サービスは、あらゆるアプリケーションのための30以上の材料のためのあなたの付加製造業の生産センターである、3D印刷サービス 我々はあなたのすべての要件を満たすために3D印刷の専門家である 工業用グレード。

ウレタン鋳造サービス

部品の急速なプロトタイピングおよび生産のために作ることは、10日、あらゆるpart.Ourのための100%点検のための100%検査証明されるISO 9001はあなたの製品開発の等級質をあらゆるbatch.Weであるポリウレタン材料の専門家届ける