ウォータージェット切断サービス

部品の急速なプロトタイピングと生産のために作る、最速10日の部品、各部品の100%検査

- 最低注文数量なし

- 迅速な製造 日数

- ラピッドプロトタイピングとフルプロダクションラン

- 30種類以上の金属とプラスチック素材をご用意

- ISO 9001認証取得の高品質をすべてのバッチでお届けします。

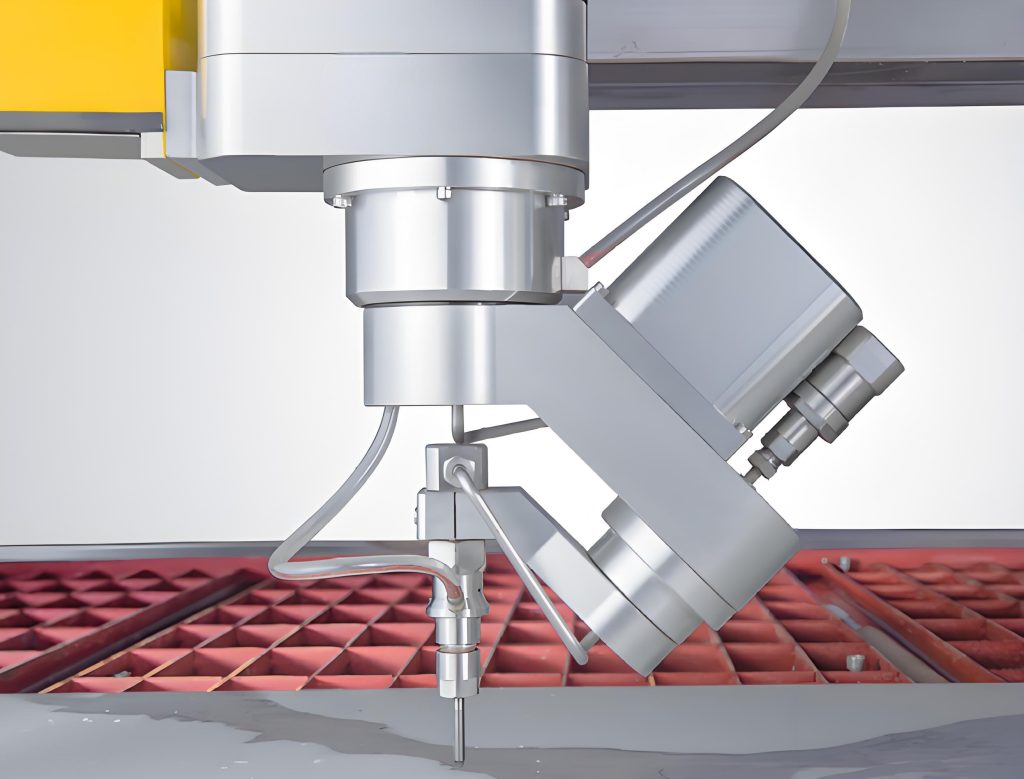

ウォータージェット切断とは

ウォータージェット切断の主要メーカー

ウォータージェットとは、高圧または超高圧ポンプで通常の水媒体を加圧し、亜音速または超音速でノズル(オリフィス)を通して噴射し、高速、高エネルギー、高浸透の水ビームを形成するものである。主に高圧発生システム、ノズルアセンブリ、制御バルブグループ、高圧配管継手の4つの部品で構成されている。レーザー切断とは異なり、ウォータージェット切断は熱を使用せず、むしろ冷間切断プロセスである。

水切断ジェット技術がうまく適用されている産業には、機械製造、自動車、航空宇宙、軍需産業、電子電力、石油化学、軽工業、海運、食品、医療、環境保護、建設資材、都市工学などがある。

研磨ウォータージェット切断の特徴

段ボールから鋼板、花崗岩、セラミック、コンクリートなど、あらゆる材質の切断が可能。

冷間切断工具。アブレイシブウォータージェットで切断する場合、ワークの温度は80℃以内で、熱応力や熱変形が全くありません。特に熱に弱い材料、特殊合金材料、複合材料の切断に適している。

環境に優しく、安全です。アブレシブウォータージェット切断は、粉塵や有毒ガスを発生せず、二次汚染もなく、安全でクリーンな作業環境を提供することができます。

高い自動化と柔軟性。CNCシステムの助けを借りて、どんな複雑な形状の特殊形状の切断も行うことができ、切断は滑らかで、加工精度は高く、二次加工は必要ない。顧客は便利にコンピュータ上で直接必要な工作物を描画、入力またはスキャンし、工作物の材料の種類、厚さ、必要な切断品質を選択し、対応する加工パラメータを設定し、最終製品を形成するために処理を開始することができます。

研磨ウォータージェット切断は、投資コストが低く、生産効率が高く、経済的な利点がある。

ウォータージェット特殊加工には次のような利点があります。

多種多様な素材に対応:

特殊合金:チタン合金、ニッケル-鉄合金、ニッケル基合金、銅、黄銅、アルミニウムなどの非鉄金属、鉄鋼など

切断面が滑らかで、二次加工が最小限で済む。

驚異的な精度とコストパフォーマンス

アブレイシブウォータージェット加工は、熱をほとんど発生させない冷間加工である。

1つの部品を加工した後、素材や形状の異なる別の部品の加工を開始するのに約2分しかかからない。

その他の製造能力

当社は3Dプリンティング、CNC機械加工、真空鋳造、射出成形、板金加工を専門としており、さまざまな素材や表面仕上げを提供しています。

CNC加工

ミルターン複合マシニングセンター、標準3軸、連続5軸、3+2軸フライス盤、ドリル加工、50種類以上の金属とプラスチックを使用した後加工があり、15種類以上の表面仕上げが可能です。公差は±0.0000394"(0.001mm)まで対応。

射出成形サービス

HOFengはあらゆる熱可塑性プラスチックの成形が可能です。カスタム製品や部品のための費用対効果の高い射出成形サービス。プロトタイプ金型は最短10日、生産金型は最短2週間、ISO9001:2015|品質検査の重要性

3Dプリントサービス

HOFengの3D印刷サービスは、あらゆるアプリケーションのための30以上の材料のためのあなたの付加製造業の生産センターである、3D印刷サービス 我々はあなたのすべての要件を満たすために3D印刷の専門家である 工業用グレード。

ウレタン鋳造サービス

部品の急速なプロトタイピングおよび生産のために作ることは、10日、あらゆるpart.Ourのための100%点検のための100%検査証明されるISO 9001はあなたの製品開発の等級質をあらゆるbatch.Weであるポリウレタン材料の専門家届ける