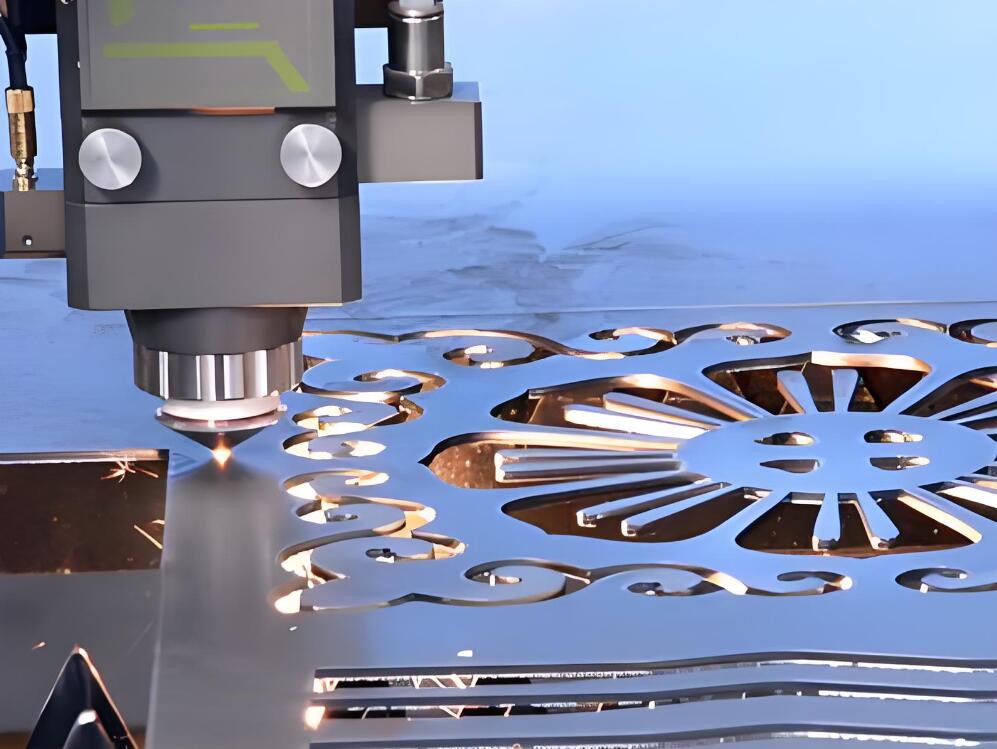

OEM製造レーザー切断サービス

当社の最先端レーザー技術は、あらゆる切断において精度と品質を保証し、複雑な形状の切断、精密な公差の達成、特殊な材料の加工など、さまざまな用途に適しています。

OEM製作レーザー切断サービス板金プラッツ

Hofengfabは、金属、プラスチック、ゴム、発泡スチロール、木材などの多様な材料に対応する包括的なオンラインカスタムレーザー切断サービスを自信を持って提供します。当社の最先端レーザー技術は、複雑な形状の切断、精密な公差の達成、ユニークな素材の加工など、さまざまな用途に適しており、すべての切断において精度と品質を保証します。

当社の広範な能力により、さまざまな種類の金属、プラスチック(アクリルを含む)、ゴム、発泡体、木材を含む幅広い材料を扱うことができます。この多様性により、試作品1個から少量生産、バッチ生産、さらには大量生産まで、お客様の幅広いニーズにお応えすることができます。

レーザー切断サービス

金属レーザー切断サービス

プラスチックレーザー切断サービス

アクリルレーザー切断サービス

木材レーザー切断サービス

レーザー切断に代わる方法

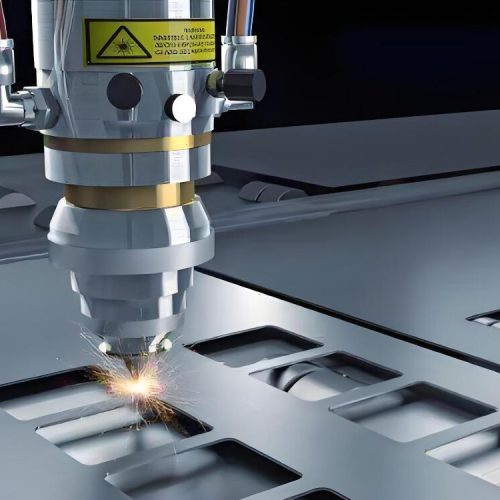

レーザー切断機には多くの種類がある。異なる分類方法によると、以下の種類があります。

レーザー切断機のサイズによって、大型レーザー切断機、卓上型レーザー切断機、デスクトップ型レーザー切断機に分けられる。

レーザー技術の違いにより、YAGレーザー切断機(クリスタルレーザー切断機)、Ndレーザー切断機、CO2レーザー切断機などに分けられる。

異なる切断材料に応じて、金属レーザー切断機と非金属レーザー切断機に分けることができます。

さまざまな応用分野に応じて、産業用レーザー切断機や教育用レーザー切断機などに分けることができます。

HOFengのレーザーカッターの種類:

C02レーザー切断機

Ndレーザー切断機

Nd:Yagレーザー切断機

CNCレーザー切断の利点と欠点

メリット

手頃な価格//切断速度が速く、高速切断や光切断などの切断方法を実現できる。

このスピードと品質の組み合わせにより、非常に競争力のある価格帯で精密製造金属部品をお届けすることができるのです。

切断品質//レーザー切断は、研削やバリ取りのような追加の仕上げ作業を必要とせずに、高品質のエッジ仕上げを持つ複雑で複雑な部品を生成します。

材質選択//炭素鋼、ステンレス鋼、アルミニウム、合金、非鉄金属など、様々な材質の金属板を効果的に切断できます。

厳しい公差//レーザー切断は高い寸法精度を持ち、鈍角や狭い継ぎ目を切断することができます。この能力により、最も厳しい品質基準を満たす部品を提供することができます。

欠点

レーザー切断は、主にレーザービームの物理的性質と材料との相互作用により、中・小板厚の板やパイプに限定されます。被加工物の厚みが増すにつれて、レーザービームが材料を貫通して切断する能力が低下し、切断速度が低下する。この限界はレーザー切断プロセスに固有のものであり、より大きな、またはより厚い加工物を計画する際には考慮する必要があります。

その他の製造能力

3Dプリンティング、CNC機械加工、真空鋳造、射出成形、板金加工に特化し、さまざまな素材や表面仕上げを提供しています。

射出成形サービス

HOFengはあらゆる熱可塑性プラスチックの成形が可能です。カスタム製品や部品のための費用対効果の高い射出成形サービス。プロトタイプ金型は最短10日、生産金型は最短2週間、ISO9001:2015|品質検査の重要性

3Dプリントサービス

HOFengの3D印刷サービスは、あらゆるアプリケーションのための30以上の材料のためのあなたの付加製造業の生産センターである、3D印刷サービス 我々はあなたのすべての要件を満たすために3D印刷の専門家である 工業用グレード。

ウレタン鋳造サービス

部品の急速なプロトタイピングおよび生産のために作ることは、10日、あらゆるpart.Ourのための100%点検のための100%検査証明されるISO 9001はあなたの製品開発の等級質をあらゆるbatch.Weであるポリウレタン材料の専門家届ける

あなたが尋ね、私たちが答える

板金加工サービス

シートメタルプロトタイピングは、迅速かつ柔軟で信頼性の高い設計の反復、テスト機能、コンセプトから市場への迅速な移行により、プロジェクトの開発を加速させます。