金属の切断と成形

3Dデータアップロードによる最速見積もり

- さまざまな素材や表面処理に対応 1ピースでも最短1日でお届け

-アップロードされたファイルは厳重に機密保護されます。

-複雑な曲げ加工や特殊形状のレーザー加工に対応

シートメタル・ベンディングとは?

板金曲げ加工は、金属板に力を加えて所望の半径を作り出す工程です。この技術には、特殊な工具を必要とせず、多様な形状の部品を製造できるという驚くべき利点があります。この分野の一般的な機械であるプレスブレーキは、主にこの目的を達成するために利用されます。

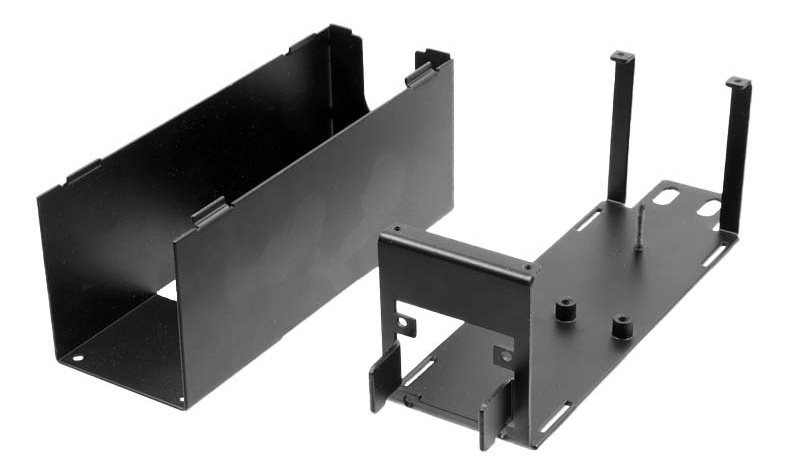

板金曲げの用途は広大かつ多様で、数多くの工業製品や消費者製品の生産に及んでいる。例えば、自動車のボディーパネル、冷凍ユニット、電子機器筐体、ブラケットなどの製造に一般的に採用されている。その多用途性により、製造業者は他の方法では容易に達成できない複雑なデザインや形状を作り出すことができる。

さらに、板金曲げ加工は、生産量が少なかったり、より薄い金属板を使用したりする場合に特に適している。このような場合、鋳造技術はコスト効率が悪く、実用的でない可能性があるため、板金曲げがより現実的な選択肢となります。これは特に、1ロットあたり数百から数千個の生産量の場合に当てはまります。

チューブ曲げサービス

パイプ曲げ加工は、パイプまたはチューブの形状を変更し、特定の要件を満たす所望の形状や機能を作成する一連の製造工程で構成されています。HOFengは、金属パイプとチューブストックのチューブ曲げ加工とチューブ加工サービスを提供し、お客様のニーズにお応えします。

板金の曲げ方

1. 板金の曲げ加工は通常、ブレーキと呼ばれる高価で特殊な工具を使って行われる。板金を手で曲げるのは、板金片が小さくて十分に薄く、扱いやすいものであれば、何とかできる作業だ。

2.チューブ曲げ

一般的に使用される管曲げ方法には、プレス曲げ、圧延曲げ、リターン曲げ、押出曲げがある。

3.プロファイルの曲げ加工

航空機のプロファイルは、主に骨格(胴体の翼や空気吸入口の隔壁、補強縁など)を作るために使用され、押出プロファイルと板曲げプロファイルの2種類に分けられる。圧延用押出形材は、等曲率と可変曲率の2種類に分けられます。一般的に使用される形材には、アングル形材とT字形材があります。

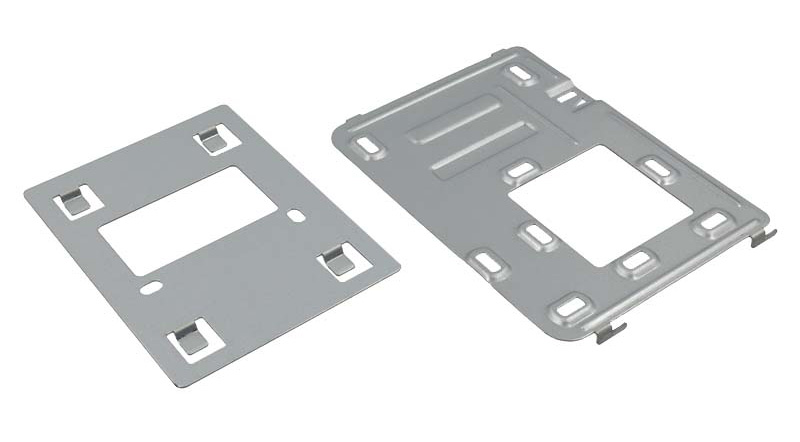

板金加工材料の種類

当社は板金部品の製造を専門としており、主にアルミニウム、ステンレス鋼、鋼合金を主要材料として使用しています。これらの金属は耐久性、耐食性、強度に優れ、様々な用途に最適です。また、真鍮や青銅の加工経験も豊富です。アルミニウム5052、5754、 ステンレススチール304、316L、軟鋼1018、銅 C110

表面仕上げと組み立て

「表面仕上げ」とは、製品の外観、表面耐久性、耐食性を向上させるために使用される工程を指します。これらの仕上げオプションには、粉体塗装、陽極酸化処理、メッキ、研磨、ブラッシングなどが含まれます。表面仕上げは、最終製品の全体的な品質と美観を高めるだけでなく、錆や腐食などの環境要因から保護するためにも不可欠です。

「二次工程」とは、最初の製造工程が完了した後に必要となる追加的な作業やサービスのことです。これらの二次加工には、CNC曲げ加工、研削加工、タッピング加工、ローレット加工などが含まれます。これらのサービスは、望ましい最終製品の仕様と品質基準を達成するために不可欠です。

その他の製造能力

3Dプリンティング、CNC機械加工、真空鋳造、射出成形、板金加工に特化し、さまざまな素材や表面仕上げを提供しています。

CNC加工

ミルターン複合マシニングセンター、標準3軸、連続5軸、3+2軸フライス盤、ドリル加工、50種類以上の金属とプラスチックを使用した後加工があり、15種類以上の表面仕上げが可能です。公差は±0.0000394"(0.001mm)まで対応。

射出成形サービス

Hofengfab はあらゆる熱可塑性プラスチックの成形が可能です。カスタム製品や部品のための費用対効果の高い射出成形サービス。プロトタイプ金型は最短10日、生産金型は最短2週間、ISO 9001:2015|品質検査に重要なこと

3Dプリントサービス

Hofengfab の 3D 印刷サービスはあらゆる適用のための 30+ 材料のためのあなたの付加製造業の生産中心、3D 印刷サービスです 私達はあなたのすべての条件を満たす 3D 印刷の専門家です 産業等級。

ウレタン鋳造サービス

部品の急速なプロトタイピングおよび生産のために作ることは、10日、あらゆるpart.Ourのための100%点検のための100%検査証明されるISO 9001はあなたの製品開発の等級質をあらゆるbatch.Weであるポリウレタン材料の専門家届ける