Solusi untuk industri minyak dan gas

- Sangat cocok dengan katup, bushing, dan sensor presisi untuk meningkatkan efisiensi operasi infrastruktur energi.

Mendukung layanan manufaktur komponen presisi energi

HOFeng memiliki beberapa tahun pengalaman dalam pembuatan dan pemrosesan suku cadang presisi. Dengan desain industri yang matang dan proses pemrosesan, serta berbagai peralatan dan peralatan mesin CNC, ia dapat membuat suku cadang presisi dalam kombinasi.

Peralatan energi mengandalkan aksesori presisi tinggi

Industri gas alam, minyak, dan energi mengandalkan banyak suku cadang mesin CNC, dan katup presisi, bushing, dan peralatan sensor semuanya membutuhkan suku cadang mesin presisi. Untuk mempertahankan operasi yang efisien dari infrastruktur energi yang penting, komponen harus dikoordinasikan dengan sempurna. Suku cadang yang digunakan di lingkungan yang keras membutuhkan presisi tinggi, serta ketahanan korosi dan panas yang tinggi, dan logam-logam ini biasanya membutuhkan alat pemotong CNC modern.

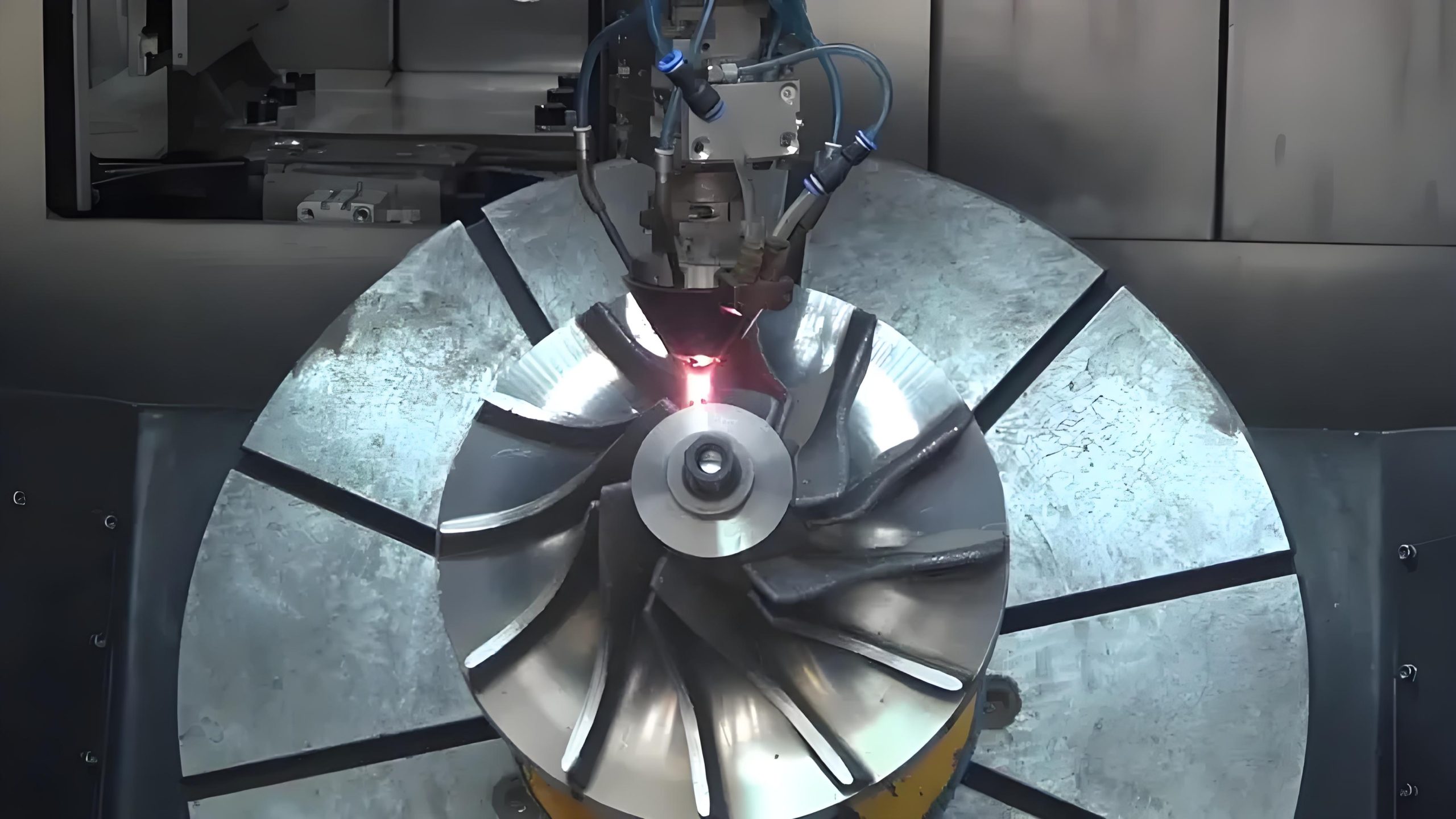

Teknologi manufaktur hibrida

Di bidang manufaktur suku cadang presisi, HOFeng telah menguasai teknologi manufaktur hibrida dan mampu menghasilkan komponen yang lebih presisi dan berkualitas tinggi dengan biaya lebih rendah dan lebih cepat. Ini memiliki keuntungan besar dalam pembuatan berbagai suku cadang presisi dan menggabungkan peralatan pendukung.

Keunggulan teknologi manufaktur hibrida

Selain mampu menghasilkan suku cadang yang lebih presisi dan berkualitas tinggi dengan lebih cepat, teknologi manufaktur hibrida juga memiliki beberapa keunggulan

- Meningkatkan produktivitas dan mempercepat kecepatan produksi

- Mencapai akurasi yang lebih tinggi dan toleransi yang lebih ketat

- Meningkatkan kinerja mekanis dan menghemat biaya

- Mengurangi biaya investasi dan operasional di muka

- Secara signifikan mengurangi waktu produksi

Kekurangan teknologi manufaktur hibrida

- Investasi peralatan awal yang tinggi dalam manufaktur hibrida

- Manufaktur campuran membutuhkan persyaratan operator yang tinggi

HOFeng membantu perusahaan yang membutuhkan pembuatan suku cadang presisi dengan menyediakan layanan terintegrasi mulai dari desain hingga produk jadi melalui peralatan yang ada dan operator yang terampil.

Manufaktur suku cadang presisi untuk peralatan energi

Kemampuan Manufaktur Kami yang Lain

Kami Mengkhususkan Diri Dalam Pencetakan 3D, Pemesinan CNC, Pengecoran Vakum, Cetakan Injeksi Dan Fabrikasi Lembaran Logam, Menawarkan Berbagai Macam Bahan Dan Permukaan Akhir.

Mesin CNC

Kami memiliki pusat permesinan komposit Mill-turn, mesin milling 3-sumbu, 5-sumbu kontinu, 3+2 sumbu standar, pengeboran dan pasca-pemrosesan menggunakan lebih dari 50 jenis logam dan plastik yang berbeda, tersedia dalam lebih dari 15 permukaan akhir. Toleransi hingga ±.0000394 "(0.001mm)

Layanan Cetakan Injeksi

HOFeng dapat mencetak termoplastik apa pun. Layanan pencetakan injeksi yang hemat biaya untuk produk dan suku cadang khusus Anda. Alat Prototipe Dalam Waktu 10 Hari Alat Produksi Dalam Waktu 2 Minggu, ISO 9001: 2015 | Penting untuk Inspeksi Kualitas

Layanan Pencetakan 3D

Layanan Pencetakan 3D HOFeng adalah pusat produksi manufaktur aditif Anda untuk 30+ bahan untuk aplikasi apa pun, layanan pencetakan 3D Kami Ahli Pencetakan 3D Untuk Memenuhi Semua Kebutuhan Anda Kelas Industri.

Layanan Pengecoran Uretan

Membuat prototipe dan produksi suku cadang yang cepat, Suku cadang secepat 10 hari, inspeksi 100% untuk setiap suku cadang Bersertifikat ISO 9001 kami memberikan kualitas kelas dengan setiap batch Kami adalah ahli bahan poliuretan dalam pengembangan produk Anda