Pencetakan SLS layanan

Membuat prototipe dan produksi suku cadang yang cepat, Suku cadang secepat 10 hari, inspeksi 100% untuk setiap suku cadang

Bersertifikat ISO 9001 kami memberikan kualitas kelas dengan setiap batch

- Tidak ada jumlah pesanan minimum

- Dibuat dengan Cepat dalam Beberapa Menit Hari

- Pembuatan Prototipe Cepat dan Proses Produksi Penuh

- Lebih dari 30+ Bahan Logam dan Plastik Tersedia

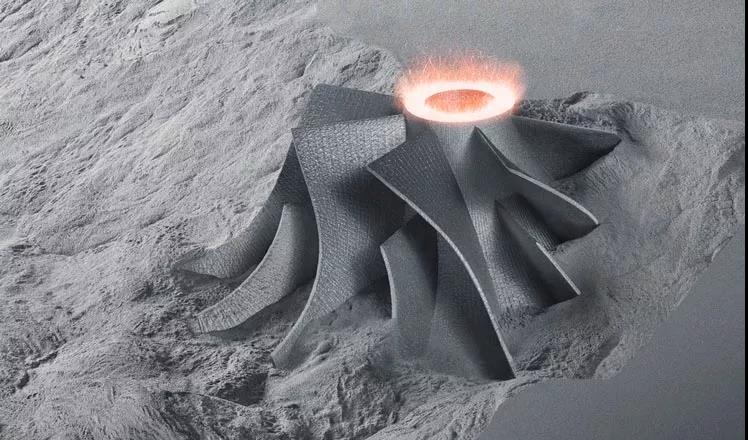

apa itu pencetakan 3d SLS

Selective Laser Sintering (SLS), juga dikenal sebagai selective laser sintering atau teknologi sintering laser selektif, pertama kali diusulkan oleh Carl Deckard dari Texas University di Amerika Serikat, dan peralatan prototipe komersial secara resmi diluncurkan di pasar pada tahun 1992.

Teknologi pencetakan 3D sintering laser terutama menggunakan prinsip dasar sintering suhu tinggi dari bahan bubuk di bawah iradiasi laser, dan menyadari pemosisian yang tepat melalui perangkat pemosisian sumber cahaya yang dikendalikan komputer, dan kemudian menyinter dan menumpuk lapis demi lapis. Oleh karena itu, teknologi SLS juga menggunakan metode susun dan susun. Perbedaan utama adalah bahwa sebelum iradiasi, lapisan bahan bubuk perlu diletakkan, dan kemudian bahan dipanaskan terlebih dahulu ke suhu yang sedikit lebih rendah dari titik leleh, dan kemudian perangkat iradiasi laser digunakan untuk memindai penampang lapisan, sehingga suhu bagian yang disinari bubuk naik ke titik leleh, sehingga disinter untuk membentuk ikatan. Kemudian proses peletakan bubuk dan sintering diulangi sampai seluruh model dicetak.

Proses SLS terutama mendukung bahan baku bubuk, termasuk bubuk logam dan bubuk non-logam, dan kemudian menumpuknya dengan iradiasi laser dan prinsip sintering. Prinsip pencetakan SLS sangat mirip dengan SLA, perbedaan utamanya terletak pada bahan yang digunakan dan bentuknya. Bahan baku yang digunakan oleh SLA terutama adalah resin cair yang dapat disembuhkan yang peka terhadap sinar UV, sedangkan SLS menggunakan bahan bubuk.

bagaimana cara kerja pencetakan 3d SLS

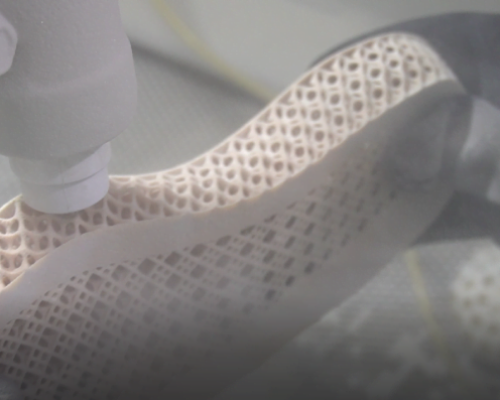

√Selama pencetakan, seluruh ruang pencetakan selalu dijaga pada suhu yang sedikit lebih rendah daripada titik leleh bahan bubuk.

√ Bubuk bahan disebarkan pada permukaan atas bagian yang dibentuk dan dikikis rata.

√ Laser CO2 intensitas tinggi digunakan untuk menyinari bagian lapisan pada bagian yang baru diletakkan. Serbuk bahan disinter bersama di bawah penyinaran laser intensitas tinggi dan diikat ke bagian yang terbentuk di bawahnya.

√Setelah lapisan penampang disinter, lapisan baru bahan bubuk diletakkan melalui sistem peletakan bubuk, dan kemudian lapisan penampang berikutnya dicetak.

Bahan Pencetakan 3D SLS

Selective laser sintering (SLS) sering kali menggunakan nilon sebagai bahan utamanya, termoplastik rekayasa serbaguna yang terkenal dengan kemampuannya yang serba guna dalam pembuatan prototipe fungsional dan produksi penggunaan akhir.

Komponen nilon SLS unggul dalam hal kekuatan, kekakuan, dan daya tahan. Produk akhir ini memiliki ketahanan benturan yang luar biasa, tahan terhadap keausan berulang tanpa mengorbankan integritasnya. Selain itu, ketahanan nilon yang melekat terhadap paparan sinar UV, cahaya, panas, kelembapan, pelarut, fluktuasi suhu, dan air memastikan kinerja yang lama dan umur yang panjang.

Selain itu, komponen nilon SLS juga dapat bersifat biokompatibel dan tidak menyebabkan sensitisasi, sehingga aman untuk kontak langsung dengan kulit dan cocok untuk berbagai aplikasi. Keserbagunaan dan daya tahan ini membuat komponen nilon SLS menjadi pilihan utama untuk berbagai industri, mulai dari otomotif hingga medis, yang membutuhkan komponen yang kuat dan tahan lama.

Keuntungan dan kerugian SLS

Keuntungan SLS:

(1) Dapat menghasilkan produk dengan kekuatan tinggi dan sifat material yang sangat baik, dan bahkan dapat digunakan langsung sebagai produk akhir

(2) Ada banyak jenis bahan mentah yang tersedia, termasuk plastik rekayasa, lilin, logam, bubuk keramik, dll.

(3) Waktu konstruksi komponen pendek, dan ketepatan objek yang dicetak sangat tinggi

(4) Tidak perlu mendesain dan membuat komponen pendukung.

Kekurangan SLS:

(1) Komponen utama memiliki tingkat kehilangan yang tinggi dan memerlukan lingkungan laboratorium khusus.

(2) Kontrol suhu yang stabil diperlukan selama pencetakan, dan pemanasan serta pendinginan diperlukan sebelum dan sesudah pencetakan, dan pasca-pemrosesan juga merepotkan.

(3) Harga bahan baku dan biaya pengadaan serta pemeliharaan yang tinggi.

(4) Permukaan cetakan dibatasi oleh ukuran partikel serbuk dan titik laser, yang memengaruhi akurasi pencetakan.

(5) Tidak mungkin untuk secara langsung mencetak desain berongga yang tertutup sepenuhnya, dan lubang harus dibiarkan untuk menghilangkan bahan bubuk

Kemampuan Manufaktur Kami yang Lain

Kami Mengkhususkan Diri Dalam Pencetakan 3D, Pemesinan CNC, Pengecoran Vakum, Cetakan Injeksi Dan Fabrikasi Lembaran Logam, Menawarkan Berbagai Macam Bahan Dan Permukaan Akhir.

Mesin CNC

Kami memiliki pusat permesinan komposit Mill-turn, mesin milling 3-sumbu, 5-sumbu kontinu, 3+2 sumbu standar, pengeboran dan pasca-pemrosesan menggunakan lebih dari 50 jenis logam dan plastik yang berbeda, tersedia dalam lebih dari 15 permukaan akhir. Toleransi hingga ±.0000394 "(0.001mm)

Fabrikasi Lembaran Logam

HOFeng dilengkapi dengan pengelasan robot CO2, pemolesan robot, pengelasan laser robot, pengelasan platform laser, mesin pemotong laser, pengelasan laser genggam, mesin punch CNC, mesin bending, mesin deburring otomatis untuk meningkatkan kecepatan dan kemampuan untuk mengatasi aplikasi produksi massal.

Layanan Pengecoran Uretan

Membuat prototipe dan produksi suku cadang yang cepat, Suku cadang secepat 10 hari, inspeksi 100% untuk setiap suku cadang Bersertifikat ISO 9001 kami memberikan kualitas kelas dengan setiap batch Kami adalah ahli bahan poliuretan dalam pengembangan produk Anda