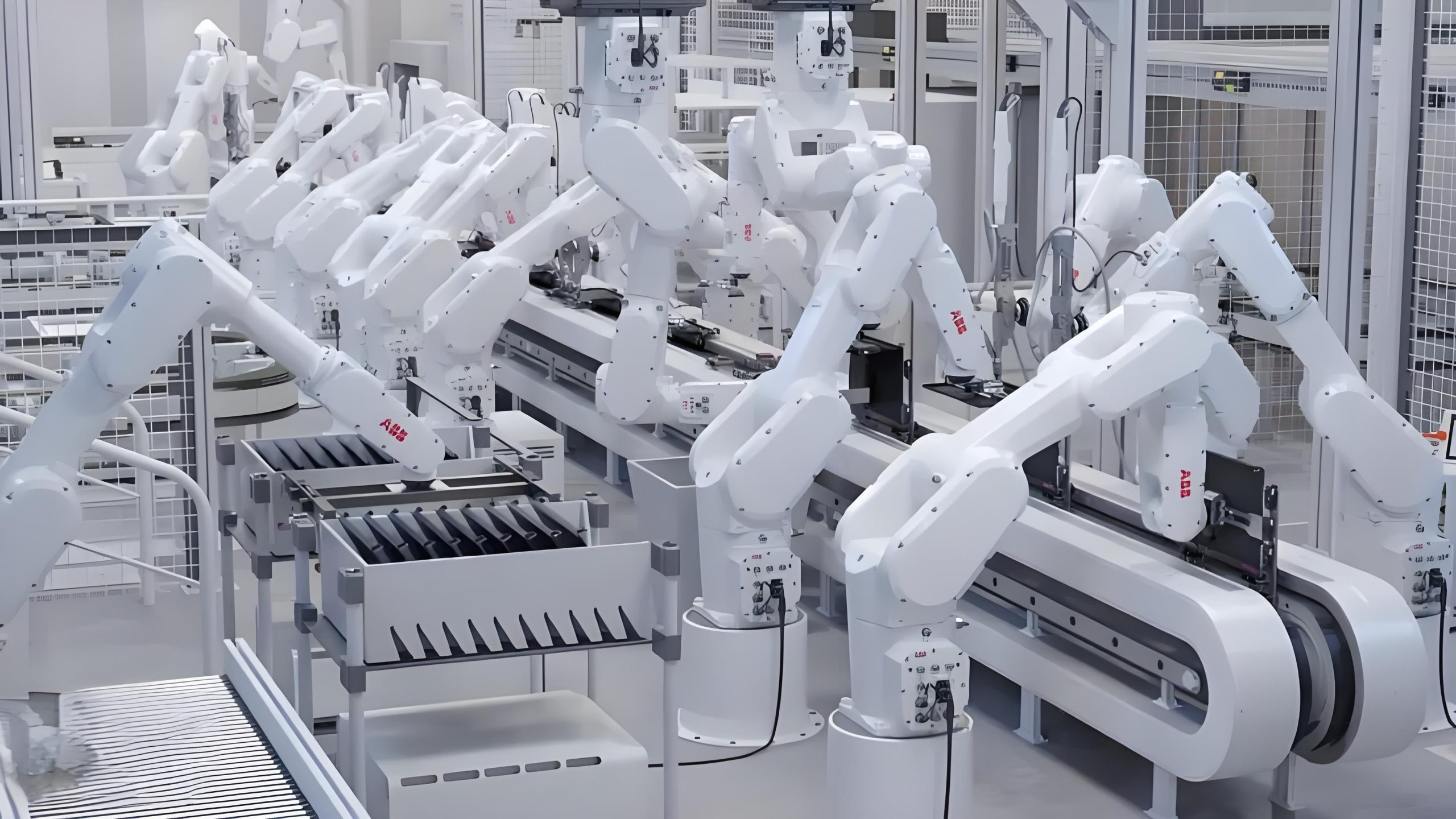

로봇 제조 분야의 솔루션

- 부품 설계 및 가공과 같은 통합 프로세스를 포함한 로봇 부품의 대량 생산을 위한 솔루션입니다.

로봇 부품 제조 서비스

다년간의 CNC 가공 경험을 바탕으로 HOFeng은 로봇 부품의 설계 및 가공에 깊은 기반을 가지고 있으며, 부품의 강도와 정확성을 보장하기 위해 대량의 부품 가공을 완료할 수 있습니다.

로봇 부품의 통합 설계 및 제조의 이점

로봇 부품 설계와 제조의 통합은 생산된 부품이 제품 설계의 정밀도에 더 부합하도록 보장하여 부품 제조 및 조립에 더 도움이 될 수 있습니다.

성숙한 산업 생산 프로세스

HOFeng은 제품 설계에서 완제품 생산, 최종 조립에 이르기까지 완벽한 산업 생산 프로세스를 갖춘 CNC 가공 분야에서 경험을 보유하고 있습니다. 성숙한 산업 프로젝트 경험을 바탕으로 맞춤형 부품 생산에 대한 고객의 요구를 최대한 충족시킬 수 있습니다.

로봇과 CNC 공작 기계의 관계

CNC 공작 기계의 도움으로 프로그래밍 지침, 센서 피드백 및 기타 방법을 통해 로봇의 동작, 동작 및 작업을 제어하여 자동화된 작업 및 생산 제어를 달성하는 상호 작용이 이루어집니다. 제조 산업에서는 생산 효율성, 정확성 및 일관성을 개선하고 인적 오류를 줄이며 생산 비용을 낮추고 복잡한 부품 처리와 같은 이점을 달성하여 생산 프로세스를 더욱 지능적으로 만들고 생산 효율성을 향상시킬 수 있습니다.

CNC 가공에서 로봇의 발전 추세

산업 지능의 발전과 함께 CNC 기술과 로봇은 모두 빠르게 발전하고 있습니다. UoAo 로봇과 마찬가지로 로봇의 적용 시나리오도 점점 더 광범위하고 복잡해지고 있습니다. 이에 따라 CNC 기술은 점점 더 복잡해지고 성숙해져 더 많은 과제에 적응하고 인간에게 더 효율적이고 정확하며 유연한 생산 모드를 제공할 것입니다.

로봇 부품 설계 및 가공 서비스

기타 제조 역량

당사는 3D 프린팅, CNC 가공, 진공 주조, 사출 성형 및 판금 제작을 전문으로 하며 다양한 재료와 표면 마감을 제공합니다.

CNC 가공

당사는 밀턴 복합 머시닝 센터, 표준 3축, 연속 5축, 3+2축 밀링 머신, 50개 이상의 다양한 금속 및 플라스틱을 사용한 드릴링 및 후가공을 15개 이상의 표면 마감으로 제공하고 있습니다. 공차 ±.0000394"(0.001mm )

사출 성형 서비스

HOFeng은 모든 열가소성 플라스틱을 성형할 수 있습니다. 맞춤형 제품 및 부품을위한 비용 효율적인 사출 성형 서비스. 빠르면 10 일 안에 프로토 타입 도구 빠르면 2 주 안에 생산 도구, ISO 9001 : 2015 | 품질 검사에 중요

3D 프린팅 서비스

HOFeng의 3D 프린팅 서비스는 모든 애플리케이션을위한 30 개 이상의 재료, 3D 프린팅 서비스를위한 적층 제조 생산 센터입니다. 우리는 모든 요구 사항을 충족하는 3D 프린팅 전문가입니다 산업 등급.

우레탄 주조 서비스

부품의 신속한 프로토 타이핑 및 생산을위한 제작, 10 일의 빠른 부품, 모든 부품에 대한 100% 검사, ISO 9001 인증은 모든 배치에 등급 품질을 제공합니다. 우리는 제품 개발의 폴리 우레탄 소재 전문가입니다.