Pemotongan dan Pembentukan Logam

Penawaran Tercepat Dengan Mengunggah Data 3D

- Mengakomodasi Berbagai Bahan Dan Perawatan Permukaan Pengiriman Tercepat Dalam 1 Hari, Bahkan Untuk 1 Buah

-File yang Anda Unggah Sangat Rahasia dan Aman

-Mengakomodasi Pembengkokan Kompleks dan Pemrosesan Laser Bentuk Khusus

Apa yang dimaksud dengan Pembengkokan Lembaran Logam?

Pembengkokan lembaran logam adalah proses yang melibatkan pengerahan kekuatan pada lembaran logam untuk menciptakan radius yang diinginkan. Teknik ini menawarkan keuntungan yang luar biasa karena dapat membuat beragam geometri komponen tanpa memerlukan perkakas khusus. Rem tekan, mesin yang umum digunakan dalam bidang ini, terutama digunakan untuk mencapai tujuan ini.

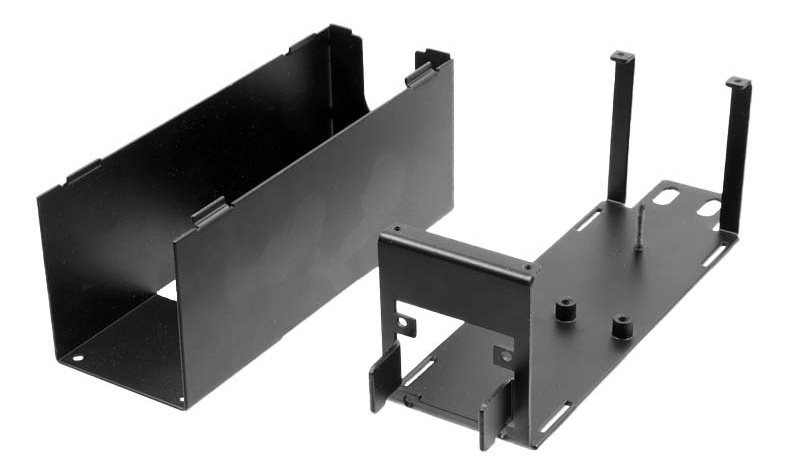

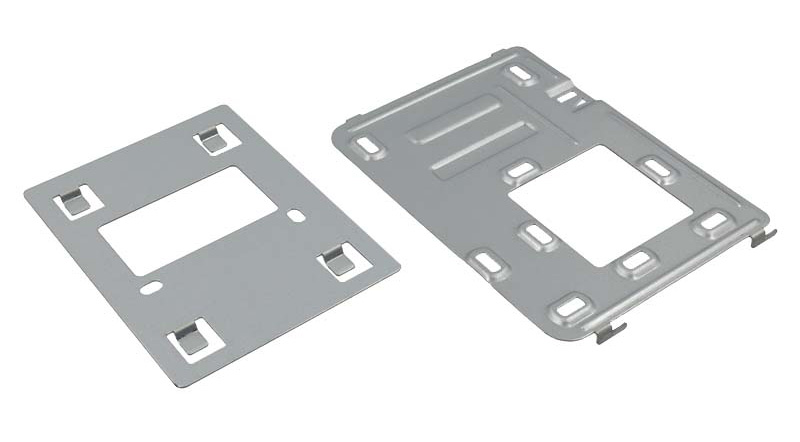

Aplikasi pembengkokan lembaran logam sangat luas dan beragam, meluas ke produksi berbagai produk industri dan konsumen. Sebagai contoh, biasanya digunakan dalam pembuatan panel bodi kendaraan, unit pendingin, penutup elektronik, dan braket. Fleksibilitasnya memungkinkan produsen untuk membuat desain dan bentuk yang rumit yang tidak mudah dicapai melalui metode lain.

Selain itu, pembengkokan lembaran logam sangat cocok untuk skenario yang melibatkan volume produksi yang lebih rendah atau penggunaan lembaran logam yang lebih tipis. Dalam kasus seperti itu, teknik pengecoran mungkin tidak hemat biaya atau praktis, sehingga membuat pembengkokan lembaran logam menjadi pilihan yang lebih layak. Hal ini terutama berlaku untuk proses produksi yang berkisar antara beberapa ratus hingga beberapa ribu unit per lot.

Layanan Pembengkokan Tabung

Pembengkokan tabung terdiri dari serangkaian proses manufaktur yang mengubah bentuk pipa atau tabung untuk menciptakan geometri atau fitur yang diinginkan yang memenuhi persyaratan tertentu. HOFeng menawarkan layanan pembengkokan tabung dan fabrikasi tabung untuk pipa logam dan stok tabung untuk memenuhi kebutuhan Anda.

Cara Membengkokkan Lembaran Logam

1. Pembengkokan lembaran logam biasanya dilakukan dengan menggunakan alat yang mahal dan khusus yang dikenal sebagai rem Pembengkokan lembaran logam dengan tangan adalah tugas yang mudah dilakukan jika potongan lembaran logam kecil dan cukup tipis untuk ditangani.

2. Pembengkokan Tabung

Metode pembengkokan tabung yang umum digunakan meliputi pembengkokan tekan, pembengkokan bergulir, pembengkokan balik, dan pembengkokan ekstrusi.

3. Pembengkokan profil

Profil pada pesawat terbang terutama digunakan untuk membuat kerangka (sayap badan pesawat dan sekat saluran masuk udara, tepi penguat, dll.), yang dibagi ke dalam dua kategori: profil yang diekstrusi dan profil pembengkokan pelat. Profil yang diekstrusi untuk penggulungan dapat dibagi menjadi dua jenis: kelengkungan yang sama dan kelengkungan variabel. Bagian profil yang umum digunakan termasuk profil sudut dan profil berbentuk T.

Jenis Bahan Fabrikasi Lembaran Logam

Perusahaan kami mengkhususkan diri dalam produksi komponen lembaran logam, terutama menggunakan aluminium, baja tahan karat, dan paduan baja sebagai bahan utama kami. Logam-logam ini menawarkan daya tahan, ketahanan terhadap korosi, dan kekuatan yang sangat baik, sehingga ideal untuk berbagai aplikasi. Kami juga telah mengumpulkan pengalaman yang luas bekerja dengan kuningan dan perunggu, dan kami dapat menyediakan jenis lembaran logam lainnya berdasarkan permintaan.Aluminium 5052, 5754, Baja tahan karat 304, 316L,Baja ringan 1018,Tembaga C110

Penyelesaian Permukaan & Perakitan

"Finishing Permukaan" mengacu pada proses yang digunakan untuk meningkatkan tampilan, daya tahan permukaan, dan ketahanan korosi suatu produk. Pilihan finishing ini termasuk pelapisan bubuk, anodisasi, pelapisan, pemolesan, pemolesan, penyikatan, dan banyak lagi. Finishing permukaan sangat penting untuk meningkatkan kualitas dan estetika produk akhir secara keseluruhan, serta melindunginya dari faktor lingkungan seperti karat dan korosi.

"Proses Sekunder" mengacu pada operasi atau layanan tambahan yang mungkin diperlukan setelah proses manufaktur awal selesai. Proses sekunder ini dapat mencakup aktivitas seperti pembengkokan CNC, penggilingan, penyadapan, knurling, dan banyak lagi. Layanan ini sangat penting untuk mencapai spesifikasi produk akhir dan standar kualitas yang diinginkan.

Kemampuan Manufaktur Kami yang Lain

Kami Mengkhususkan Diri Dalam Pencetakan 3D, Pemesinan CNC, Pengecoran Vakum, Cetakan Injeksi Dan Fabrikasi Lembaran Logam, Menawarkan Berbagai Macam Bahan Dan Permukaan Akhir.

Mesin CNC

Kami memiliki pusat permesinan komposit Mill-turn, mesin milling 3-sumbu, 5-sumbu kontinu, 3+2 sumbu standar, pengeboran dan pasca-pemrosesan menggunakan lebih dari 50 jenis logam dan plastik yang berbeda, tersedia dalam lebih dari 15 permukaan akhir. Toleransi hingga ±.0000394 "(0.001mm)

Layanan Cetakan Injeksi

Hofengfab dapat mencetak termoplastik apa pun. Layanan pencetakan injeksi yang hemat biaya untuk produk dan suku cadang khusus Anda. Alat Prototipe Dalam Waktu 10 Hari Alat Produksi Dalam Waktu 2 Minggu, ISO 9001: 2015 | Penting untuk Inspeksi Kualitas

Layanan Pencetakan 3D

Layanan Pencetakan 3D Hofengfab adalah pusat produksi manufaktur aditif Anda untuk 30+ bahan untuk aplikasi apa pun, layanan pencetakan 3D Kami Ahli Pencetakan 3D Untuk Memenuhi Semua Kebutuhan Anda Kelas Industri.

Layanan Pengecoran Uretan

Membuat prototipe dan produksi suku cadang yang cepat, Suku cadang secepat 10 hari, inspeksi 100% untuk setiap suku cadang Bersertifikat ISO 9001 kami memberikan kualitas kelas dengan setiap batch Kami adalah ahli bahan poliuretan dalam pengembangan produk Anda