Penawaran tercepat dengan mengunggah data 3D

Pemotongan dan Pembentukan Logam

- Mengakomodasi pembengkokan yang rumit dan pemrosesan laser untuk bentuk khusus

- Mengakomodasi berbagai bahan dan perawatan permukaan Pengiriman tercepat dalam 1 hari, bahkan untuk 1 buah

File yang Anda unggah sangat rahasia dan aman

Layanan Pemotongan dan Pembentukan Logam

Bekerja dengan berbagai metode pemrosesan dan bentuk khusus seperti pemotongan laser, pelubangan dan pembuatan sarang CNC, pembengkokan, dan penyemprotan.

Bekerja dengan berbagai metode pemrosesan dan bentuk khusus seperti pemotongan laser, pelubangan dan pembuatan sarang CNC, pembengkokan, dan penyemprotan.

Bekerja dengan berbagai bahan seperti baja tahan karat, baja karbon, dan paduan aluminium.

Mampu mengidentifikasi jenis lubang secara otomatis.

Kemampuan Fabrikasi Lembaran Logam

HOFeng dilengkapi dengan pengelasan robot CO2, pemolesan robot, pengelasan laser robot, pengelasan platform laser, mesin pemotong laser, pengelasan laser genggam, mesin punch CNC, mesin bending, mesin deburring otomatis untuk meningkatkan kecepatan dan kemampuan untuk mengatasi aplikasi produksi massal.

perakit lembaran logam besar

Pemrosesan lembaran logam untuk sasis dan kabinet lembaran logam

Puluhan Tahun Keahlian Fabrikasi Lembaran Logam

Jika Anda mencari perakit lembaran logam yang dapat menangani segala sesuatu mulai dari pengembangan produk baru dan suku cadang prototipe hingga proses produksi besar dan layanan perakitan, HOFeng adalah pilihan yang lebih baik dari yang Anda harapkan. para ahli kami mengelola setiap langkah proses, mulai dari bantuan desain dan fabrikasi logam hingga pengecatan, sablon, pembuatan kit, dan perakitan.

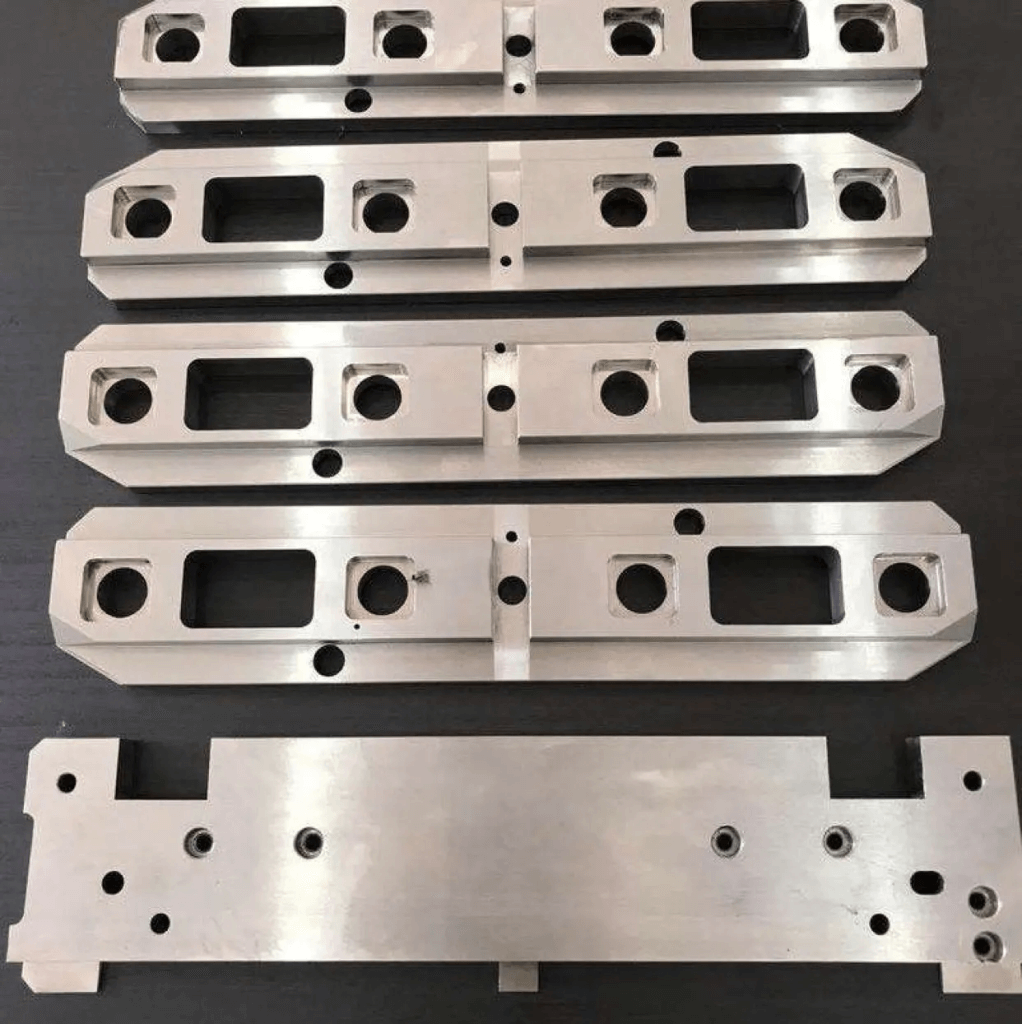

Meninju CNC

Mesin press CNC kami dapat secara akurat memproses fitur standar dan bentuk kompleks menjadi lembaran logam untuk memenuhi kebutuhan Anda. Turret punch yang kami gunakan dapat meninju dengan ketebalan hingga 1/4 inci dan Kami juga dapat memproduksi fitur-fitur khusus seperti countersink, manik-manik, dan kisi-kisi.

pembengkokan lembaran logam

ISO9001

Waktu tunggu secepat satu hari

Aluminium, Baja, Baja Tahan Karat, dan lainnya

Mesin tekuk lembaran logam terutama digunakan untuk menekuk lembaran dalam garis lurus. Proses pembengkokan pers terutama digunakan untuk pemrosesan suku cadang dengan batch produksi besar, bentuk yang rumit, dan persyaratan presisi tinggi.

Memberikan sudut yang akurat dengan layanan pembengkokan kami, mencapai produk akhir yang sesuai dengan toleransi yang ketat.

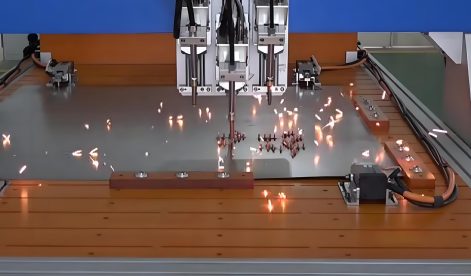

fabrikasi lembaran logam layanan pemotongan laser

Pemotongan laser menggunakan laser yang kuat yang diintensifkan melalui lensa atau cermin. Ini adalah mesin yang presisi dan hemat energi yang cocok untuk lembaran logam tipis atau sedang, tetapi mungkin mengalami kesulitan untuk menembus bahan yang paling sulit.

Pemotongan Jet Air

Pemotongan jet air adalah metode pembuatan lembaran logam yang menggunakan jet air bertekanan tinggi (dicampur dengan bahan abrasif) untuk memotong logam. Layanan pemotongan jet air HOFeng adalah solusi serbaguna dan hemat biaya untuk bagian logam presisi yang dipotong dengan tingkat akurasi yang tinggi, mesin jet air format besar kami dapat memotong bahan hingga setebal 6 inci dengan toleransi 0,005 ″ - 0,015 ″.

Pemotongan Plasma CNC

Pemotongan plasma lebih efektif untuk memotong logam non-besi (baja tahan karat, aluminium, tembaga, titanium, nikel); keuntungan utamanya adalah saat memotong logam dengan ketebalan kecil, kecepatan pemotongan plasma cepat, terutama memotong pelat tipis baja karbon biasa. Layanan pemotongan plasma HOFeng dapat menyediakan suku cadang kompleks dengan presisi tinggi pada bahan seperti aluminium, baja, dan baja tahan karat.

Sinker dan Wire EDM

Sinker EDM melibatkan penggunaan muatan listrik untuk mengikis permukaan benda kerja untuk menciptakan bentuk yang diinginkan. Di sisi lain, Wire EDM menggunakan kawat tipis untuk memotong benda kerja, cocok untuk pemesinan bentuk yang rumit dan presisi tinggi. Membantu persyaratan presisi tinggi dalam pembuatan benda kerja dan meningkatkan efisiensi produksi.

Berbagai Metode Pengelasan

HOFeng menawarkan empat teknik pengelasan utama: TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), MAG (Metal Active Gas), dan pengelasan CO2. Masing-masing metode ini menawarkan keunggulan unik dan cocok untuk aplikasi pengelasan yang berbeda, mulai dari pengelasan presisi hingga fabrikasi tugas berat.

Penyelesaian Permukaan & Perakitan

"Finishing Permukaan" mengacu pada proses yang digunakan untuk meningkatkan tampilan, daya tahan permukaan, dan ketahanan korosi suatu produk. Pilihan finishing ini termasuk pelapisan bubuk, anodisasi, pelapisan, pemolesan, pemolesan, penyikatan, dan banyak lagi. Finishing permukaan sangat penting untuk meningkatkan kualitas dan estetika produk akhir secara keseluruhan, serta melindunginya dari faktor lingkungan seperti karat dan korosi.

"Proses Sekunder" mengacu pada operasi atau layanan tambahan yang mungkin diperlukan setelah proses manufaktur awal selesai. Proses sekunder ini dapat mencakup aktivitas seperti pembengkokan CNC, penggilingan, penyadapan, knurling, dan banyak lagi. Layanan ini sangat penting untuk mencapai spesifikasi produk akhir dan standar kualitas yang diinginkan.

Bahan Fabrikasi Logam

Kemampuan Manufaktur Kami yang Lain

Kami Mengkhususkan Diri Dalam Pencetakan 3D, Pemesinan CNC, Pengecoran Vakum, Cetakan Injeksi Dan Fabrikasi Lembaran Logam, Menawarkan Berbagai Macam Bahan Dan Permukaan Akhir.

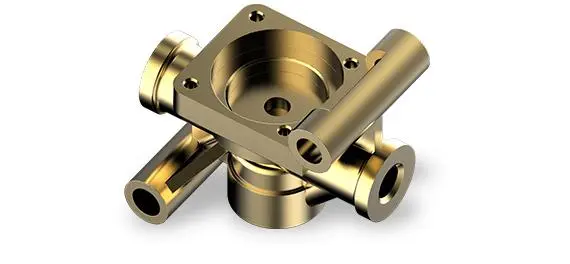

Mesin CNC

Kami memiliki pusat permesinan komposit Mill-turn, mesin milling 3-sumbu, 5-sumbu kontinu, 3+2 sumbu standar, pengeboran dan pasca-pemrosesan menggunakan lebih dari 50 jenis logam dan plastik yang berbeda, tersedia dalam lebih dari 15 permukaan akhir. Toleransi hingga ±.0000394 "(0.001mm)

Layanan Cetakan Injeksi

HOFeng dapat mencetak termoplastik apa pun. Layanan pencetakan injeksi yang hemat biaya untuk produk dan suku cadang khusus Anda. Alat Prototipe Dalam Waktu 10 Hari Alat Produksi Dalam Waktu 2 Minggu, ISO 9001: 2015 | Penting untuk Inspeksi Kualitas

Layanan Pencetakan 3D

Layanan Pencetakan 3D HOFeng adalah pusat produksi manufaktur aditif Anda untuk 30+ bahan untuk aplikasi apa pun, layanan pencetakan 3D Kami Ahli Pencetakan 3D Untuk Memenuhi Semua Kebutuhan Anda Kelas Industri.

Layanan Pengecoran Uretan

Membuat prototipe dan produksi suku cadang yang cepat, Suku cadang secepat 10 hari, inspeksi 100% untuk setiap suku cadang Bersertifikat ISO 9001 kami memberikan kualitas kelas dengan setiap batch Kami adalah ahli bahan poliuretan dalam pengembangan produk Anda

Mengapa memilih HoFeng

Presisi dan Akurasi

1. Mesin presisi dan perangkat lunak canggih kami memastikan akurasi dan konsistensi dalam setiap produk yang kami buat.

2. Proses kontrol kualitas yang ketat menjamin bahwa setiap produk memenuhi standar tinggi kami dan sesuai dengan spesifikasi.

Respon Cepat

1. Tim teknik dan operasi yang berpengalaman

2. Toko mesin internal, operasi 24/7 jam

3. Perputaran cepat, kualitas tinggi adalah prioritas utama kami

4. Membantu Anda dengan penawaran, produksi, dan pengiriman instan

Jaminan Kualitas

1. Sistem manajemen mutu kami yang bersertifikasi ISO 9001 memastikan keandalannya

2. Semua komponen diperiksa secara dimensi dengan peralatan yang dikalibrasi sehingga memenuhi spesifikasi yang tepat untuk Anda.

3.250+ Proyek Dikirim Per Bulan,10000 + SQ AREA METER, 15+ TAHUN MASA KERJA