servicios de fundición de uretano

Nuestra certificación ISO 9001 garantiza la calidad de cada lote

Somos expertos en materiales de poliuretano para el desarrollo de sus productos

- Piezas en 10 días

- Inspección 100% de cada pieza

- Creación rápida de prototipos y producción de piezas

Todas las cargas son seguras y confidenciales.

Proceso de fundición de uretano

Podemos informarle sobre los servicios de fundición de uretano. La fundición de uretano es un proceso de fabricación que consiste en crear piezas y componentes utilizando materiales de poliuretano. Este proceso se utiliza habitualmente para producir prototipos, piezas de producción de bajo volumen y componentes de repuesto.

Acabados disponibles para piezas de fundición de uretano:

Fundición de uretano mate/esmerilado

Semibrillante

Brillante

Textura personalizada

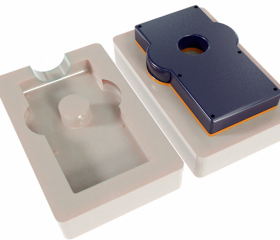

Fundición de uretano

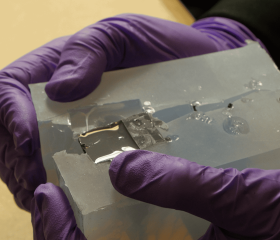

Silicona fundida//La silicona es duradera, elástica, resistente al desgarro, inerte, fácil de limpiar y resistente a altas temperaturas. Los moldes de silicona son ideales para dispositivos médicos, modelos quirúrgicos, accesorios, carcasas suaves al tacto, etc.

Los servicios de fundición de uretano suelen incluir los siguientes pasos:

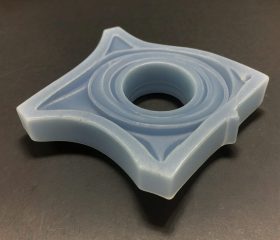

Creación de patrones maestros: Se crea un patrón maestro de la pieza deseada utilizando métodos como la impresión 3D, el mecanizado CNC o el modelado manual.

Fabricación de moldes: Las dimensiones finales de las piezas de uretano dependen de la precisión del modelo maestro, la geometría de la pieza y el material de fundición. En general, una tasa de contracción de + 0,15% es típica.

Mezcla y colada de materiales: El material de poliuretano se mezcla y se vierte en el molde. El material se cura y endurece para formar la pieza final.

Acabado de piezas: Tras el proceso de fundición, las piezas pueden someterse a procesos de acabado como recorte, lijado, pintura o tratamientos superficiales adicionales.

Si busca una empresa que ofrezca servicios de fundición de uretano, desde el diseño hasta el prototipo y la producción, nuestro equipo de ingenieros está preparado para ayudarle a hacer realidad su idea.

Aplicaciones de la fundición de uretano

La fundición de uretano es un proceso de fabricación versátil que encuentra aplicaciones en diversas industrias debido a su capacidad para producir piezas de alta calidad con geometrías complejas. Algunas aplicaciones comunes de la fundición de uretano incluyen

Creación de prototipos: La fundición de uretano se utiliza ampliamente en la creación rápida de prototipos para producir rápidamente prototipos funcionales con fines de prueba y validación antes de la producción a gran escala.

Producción de bajo volumen: Es ideal para series de producción de bajo volumen en las que el moldeo por inyección tradicional puede no ser rentable. La fundición de uretano puede producir eficazmente piezas en cantidades pequeñas y medianas.

Piezas de recambio: La fundición de uretano se utiliza a menudo para crear piezas de repuesto para maquinaria, equipos o productos que ya no se fabrican o que tienen largos plazos de entrega para los métodos de fabricación convencionales.

Aeroespacial y Defensa: La fundición de uretano se utiliza en las industrias aeroespacial y de defensa para fabricar componentes ligeros, herramientas y accesorios para aviones, satélites y aplicaciones militares.

Automóvil: La fundición de uretano se emplea en el sector de la automoción para fabricar piezas prototipo, componentes personalizados, piezas de revestimiento interior y prototipos funcionales para pruebas.

Productos sanitarios: La industria médica utiliza la fundición de uretano para desarrollar prototipos y piezas de producción de bajo volumen para dispositivos médicos, instrumentos quirúrgicos, prótesis y diseños de productos ergonómicos.

Electrónica de consumo: La fundición de uretano es popular en la industria de la electrónica de consumo para crear carcasas, cajas, botones y otros componentes personalizados para dispositivos electrónicos.

Equipos industriales: La fundición de uretano se utiliza en la fabricación de equipos industriales, componentes de maquinaria, sellos, juntas y otras piezas especializadas.

Modelos arquitectónicos: La fundición de uretano se utiliza para crear modelos arquitectónicos, elementos decorativos, señalización y réplicas a escala para presentaciones y visualizaciones de diseños.

La fundición de uretano ofrece flexibilidad, precisión y rentabilidad para producir piezas de alta calidad en el momento oportuno, lo que la convierte en la opción preferida para una amplia gama de aplicaciones en todos los sectores.

Otras capacidades de fabricación

Estamos especializados en impresión 3D, mecanizado CNC, fundición en vacío, moldeo por inyección y fabricación de chapa metálica, ofreciendo una amplia variedad de materiales y acabados superficiales.

Mecanizado CNC

Disponemos de centro de mecanizado de composites fresado-torneado, 3 ejes estándar, 5 ejes continuos, fresadora de 3+2 ejes, taladrado y postprocesado utilizando más de 50 metales y plásticos diferentes, disponibles en más de 15 acabados superficiales. Tolerancias hasta ±.0000394" (0.001mm )

Servicios de moldeo por inyección

HOFeng puede moldear cualquier termoplástico. Servicios de moldeo por inyección rentables para sus productos y piezas personalizados. Herramienta de prototipo en tan pronto como 10 días Herramienta de producción en tan pronto como 2 semanas, ISO 9001:2015 | Crítica a las inspecciones de calidad.

Servicio de impresión 3D

El servicio de impresión 3D de HOFeng es su centro de producción de fabricación aditiva para más de 30 materiales para cualquier aplicación, servicio de impresión 3D Somos expertos en impresión 3D para satisfacer todas sus necesidades de grado industrial.

Servicios de fundición de uretano

Haciendo para la creación rápida de prototipos y la producción de piezas,Piezas tan rápido como 10 días,100% inspección para cada part.Our ISO 9001 Certified entregar calidad de grado con cada batch.We son los expertos en materiales de poliuretano en su desarrollo de productos

Preguntas frecuentes sobre el colado de uretano

Si tiene una colada de uretano lista para empezar, estamos aquí para ayudarle de principio a fin. Con nuestra amplia gama de servicios opcionales de postprocesamiento y las rigurosas medidas de garantía de calidad aplicadas por nuestro departamento de control de calidad especializado, puede estar seguro de que recibirá productos que cumplirán sus expectativas.

Sólo tiene que enviarnos sus archivos CAD en 3D y nuestro equipo le proporcionará un presupuesto gratuito. Nuestros experimentados ingenieros de modelos realizarán un exhaustivo análisis de diseño para la fabricación (DFM) de su diseño, garantizando que el producto final no solo cumpla sus estándares de calidad, sino que también se ajuste a sus limitaciones presupuestarias.

¿En cuánto tiempo puedo recibir las piezas?

Las piezas de calidad de menos de 800 unidades pueden fabricarse en una semana si nos proporciona modelos CAD 2D y 3D completos. Las piezas más complejas que requieran otras características especiales tardarán más.

¿Qué consideraciones deben tenerse en cuenta al diseñar piezas para el mecanizado CNC?

Los diseñadores deben tener en cuenta factores como el acceso a las herramientas, la selección de materiales, las tolerancias y los acabados superficiales a la hora de diseñar piezas para el mecanizado CNC.

¿Cuánto suele durar un proceso de mecanizado CNC?

La duración de un proceso de mecanizado CNC depende de factores como la complejidad de la pieza, el material utilizado y las tolerancias deseadas. Puede oscilar entre minutos y horas.

¿cómo moldear goma de uretano?

Mezcle el caucho de uretano: Seleccione un material de caucho de uretano de dos componentes que cumpla los requisitos de su proyecto en cuanto a dureza, flexibilidad, color y otras propiedades. Siga las instrucciones del fabricante para mezclar los dos componentes en la proporción correcta.

Desgasificación (opcional): Para eliminar las burbujas de aire de la mezcla de goma de uretano, puede utilizar una cámara de vacío para desgasificar el material. Este paso ayuda a garantizar una fundición suave y sin burbujas.

Vertido: Vierta cuidadosamente el material de caucho de uretano mezclado en el molde. Asegúrese de verter lenta y uniformemente para evitar atrapar burbujas de aire en la mezcla.

Curado: Deje que la goma de uretano se cure y endurezca según las instrucciones del fabricante. El tiempo de curado puede variar en función del tipo específico de caucho de uretano utilizado y de las condiciones ambientales, como la temperatura y la humedad.

Desmoldeo: Una vez que la goma de uretano se haya curado por completo, retire con cuidado la pieza del molde. Dependiendo de la complejidad del molde y del diseño de la pieza, es posible que necesite utilizar agentes o técnicas de desmoldeo para facilitar el desmoldeo.

Post-procesado (Opcional): Tras el desmoldeo, puede recortar el material sobrante, limpiar la pieza y realizar cualquier paso adicional de postprocesado, como pintura, acabado o montaje, según sea necesario.

Pruebas y control de calidad: Inspeccionar la pieza de caucho de uretano fundido para detectar defectos, imperfecciones superficiales, dimensiones y calidad general. Realice las pruebas necesarias para garantizar que la pieza cumple las especificaciones y los criterios de rendimiento requeridos.

Siguiendo estos pasos y tomando las precauciones adecuadas, podrá moldear con éxito piezas de caucho de uretano para diversas aplicaciones, como prototipos, componentes industriales, moldes personalizados, sellos, juntas, etc.

¿Qué certificaciones o normas industriales cumple en sus procesos de mecanizado CNC?

HOFeng cuenta con la certificación ISO 9001 y cumple la norma ISO 13485.

¿Qué tolerancias pueden alcanzar sus máquinas CNC?

Nuestras máquinas son capaces de ofrecer tolerancias tan ajustadas como +/- 0,0002 pulgadas.

cuánto cuesta el moldeo por inyección?

En el cálculo de los costes de moldeo por inyección intervienen múltiples factores, como el diseño del producto, los costes de las materias primas, los costes de mano de obra, la depreciación de los equipos, etc.

Diseño del producto: La complejidad, el tamaño, la forma y otros factores afectarán al coste del moldeo por inyección. Algunos productos complejos pueden requerir moldes y técnicas de procesamiento especiales, y el coste aumentará en consecuencia.

Coste de las materias primas: Los distintos tipos de materias primas plásticas tienen precios diferentes, y también se ven afectados por factores como la oferta y la demanda del mercado. Las materias primas representan una proporción considerable de los costes de moldeo por inyección.

Coste del molde: el moldeo por inyección requiere el uso de moldes especialmente personalizados. Los costes de diseño, fabricación y mantenimiento del molde afectarán al coste.

Coste de mano de obra: El funcionamiento de la máquina de moldeo por inyección y el procesamiento posterior requieren la participación manual. El coste de mano de obra es una parte del coste de moldeo por inyección que no puede ignorarse.

Consumo de energía: Las máquinas de moldeo por inyección consumen una gran cantidad de energía, como electricidad y aire comprimido. Los costes energéticos también son una parte importante de los costes de moldeo por inyección.

por qué fundición de uretano

La fundición de uretano, también conocida como fundición de poliuretano, es un popular proceso de fabricación utilizado para crear piezas y prototipos de plástico de alta calidad, precisos y duraderos. Hay varias razones por las que se elige la fundición de uretano frente a otros métodos de fabricación, como el moldeo por inyección o la impresión 3D:

Rentabilidad: La fundición de uretano es una alternativa rentable al moldeo por inyección para series de producción de bajo volumen. No requiere costosos utillajes, moldes ni costes de preparación, por lo que resulta ideal para producir pequeñas cantidades de piezas sin una elevada inversión inicial.

Rapidez: La fundición de uretano permite la creación rápida de prototipos y la producción de piezas con plazos de entrega más cortos en comparación con los métodos de fabricación tradicionales. Por eso es la opción preferida para proyectos que requieren plazos de entrega rápidos.

Precisión y exactitud: La fundición de uretano produce piezas con gran precisión y exactitud, por lo que es adecuada para aplicaciones que requieren tolerancias estrechas y detalles intrincados. Las piezas pueden reproducirse con una calidad y una precisión dimensional constantes.

Amplia gama de materiales: La fundición de uretano ofrece una gran variedad de opciones de materiales con distintas propiedades, como flexibilidad, dureza y resistencia al impacto. Esta versatilidad permite personalizar y seleccionar el material más adecuado para los requisitos específicos del proyecto.

Acabados superficiales: La fundición de uretano puede conseguir una amplia gama de acabados superficiales, como mate, esmerilado, brillante o texturizado. Esto permite personalizar el aspecto y el tacto de las piezas, mejorando su atractivo estético.

Geometrías complejas: La fundición de uretano puede producir piezas con geometrías complejas, rebajes, paredes finas y características intrincadas que pueden resultar difíciles de fabricar con otros métodos. Esta versatilidad lo hace adecuado para una amplia gama de aplicaciones en diversos sectores.

Producción de bajo volumen: La fundición de uretano es idónea para series de producción de bajo volumen, pruebas de prototipos y producción puente entre iteraciones de diseño. Ofrece flexibilidad para escalar las cantidades de producción en función de la demanda sin necesidad de grandes cantidades mínimas de pedido.

En general, la fundición de uretano es un proceso de fabricación versátil, rentable y eficaz que ofrece numerosas ventajas para crear piezas y prototipos de plástico de alta calidad, precisión y opciones de personalización. Se utiliza ampliamente en sectores como la automoción, la industria aeroespacial, los dispositivos médicos, la electrónica de consumo, etc., para producir prototipos funcionales, piezas de uso final y componentes.