SLS Printing service

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part

Our ISO 9001 Certified deliver grade quality with every batch

- No minimum order quantity

- Rapidly-made in a Few Days

- Rapid Prototyping and Full Production Runs

- Over 30+ Metal and Plastic Materials Available

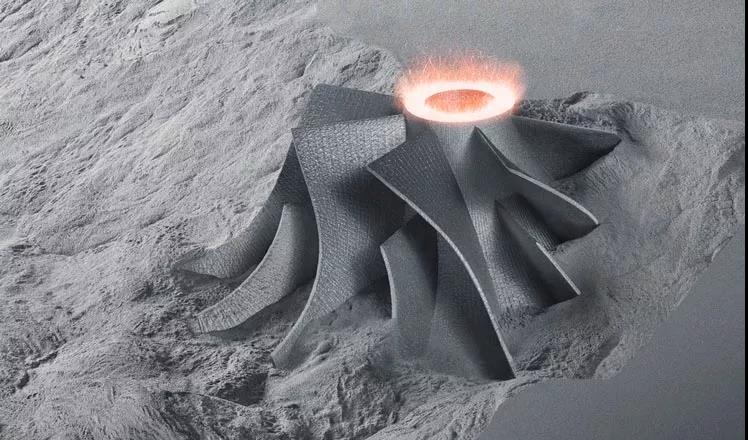

what is SLS 3d printing

Selective Laser Sintering (SLS), also known as selective laser sintering or selective laser sintering technology, was first proposed by Carl Deckard of Texas University in the United States, and the commercial prototype equipment was officially launched on the market in 1992.

Laser sintering 3D printing technology mainly uses the basic principle of high-temperature sintering of powder materials under laser irradiation, and realizes precise positioning through computer-controlled light source positioning device, and then sintering and stacking layer by layer. Therefore, SLS technology also uses the stacking and stacking method. The main difference is that before irradiation, a layer of powder material needs to be laid, and then the material is preheated to a temperature slightly lower than the melting point, and then the laser irradiation device is used to scan the cross section of the layer, so that the temperature of the irradiated part of the powder rises to the melting point, so that it is sintered to form a bond. Then the process of laying powder and sintering is repeated until the entire model is printed.

The SLS process mainly supports powdered raw materials, including metal powder and non-metallic powder, and then stacks them by laser irradiation and sintering principle. The printing principle of SLS is very similar to that of SLA, the main difference lies in the materials used and their forms. The raw materials used by SLA are mainly liquid UV-sensitive curable resins, while SLS uses powdered materials.

how does SLS 3d printing work

√During printing, the entire printing chamber is always kept at a temperature slightly lower than the melting point of the powder material.

√ The material powder is spread on the upper surface of the formed part and scraped flat.

√ A high-intensity CO2 laser is used to irradiate the layer section of the part on the newly laid layer. The material powder is sintered together under the high-intensity laser irradiation and bonded to the formed part below.

√After a layer of cross-section is sintered, a new layer of powder material is laid through the powder laying system, and then the next layer of cross-section is printed.

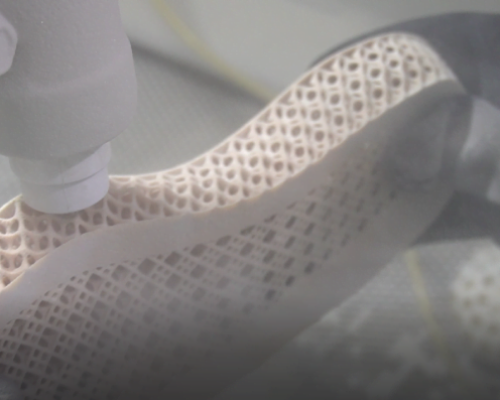

SLS 3D Printing Materials

Selective laser sintering (SLS) frequently utilizes nylon as its primary material, a versatile engineering thermoplastic renowned for its dual-purpose capabilities in functional prototyping and end-use production.

SLS nylon parts excel in terms of strength, stiffness, and durability. These final products possess remarkable impact resistance, enduring repeated wear and tear without compromising their integrity. Moreover, nylon's inherent resilience against UV exposure, light, heat, moisture, solvents, temperature fluctuations, and water ensures prolonged performance and longevity.

What's more, SLS nylon components can also be biocompatible and non-sensitizing, making them safe for direct contact with the skin and suitable for various applications. This versatility and durability make SLS nylon parts a top choice for numerous industries, from automotive to medical, where robust and long-lasting components are paramount.

SLS advantages and disadvantages

SLS advantages:

(1) It can produce products with high strength and excellent material properties, and can even be used directly as end products

(2) There are many types of raw materials available, including engineering plastics, wax, metal, ceramic powder, etc.

(3) The construction time of parts is short, and the precision of printed objects is very high

(4) No need to design and construct support parts.

SLS Disadvantages:

(1) Key components have high loss and require a special laboratory environment.

(2) Stable temperature control is required during printing, and preheating and cooling are required before and after printing, and post-processing is also troublesome.

(3) The price of raw materials and procurement and maintenance costs are high.

(4) The molding surface is limited by the size of powder particles and the laser spot, which affects the printing accuracy.

(5) It is impossible to directly print a fully enclosed hollow design, and holes need to be left to remove powder materials

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Sheet Metal Fabrication

HOFeng’s equipped with robot CO2 welding, robot polishing, robot laser welding, laser platform welding, laser cutting machine, handheld laser welding, CNC punch machine, bending machine, automatic deburring machine to improve the speed and ability to cope with mass production applications.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development