3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,Streamline and save Fast Turnaroun .We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

how much does a 3d printing service cost

Rapid prototyping drives automotive innovation

The cost of a 3D printing service can vary depending on the size and complexity of the object being printed, the type of material used, and the quality of the printer. Additional costs may also apply for design services, post-processing (such as sanding or painting), and shipping. It's best to contact our 3D printing service experter for a more accurate quote based on your project requirements.

Our 3D printing capabilities

We specialize in helping you manufacture machine parts in an efficient and timely manner. We understand the importance of getting your product to market before your competitors do. We provide quotes within hours and most parts are available in 14 days or less. Contact our experts using the form to request a quote.

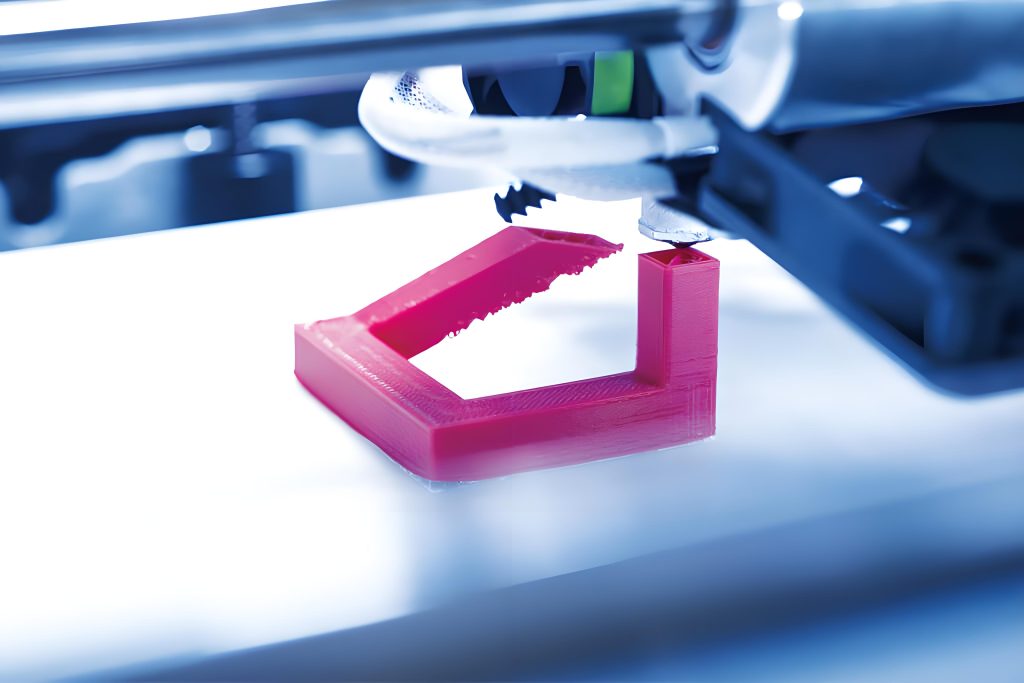

FDM 3D printing

Fused Deposition Modeling FDM 3D printing

The requirements of FDM technology for molding materials include: low melting point, good fluidity, good adhesion, and small shrinkage.

Materials available for FDM 3D printing

PLA,ABS,TPU, PP, PC, PETG

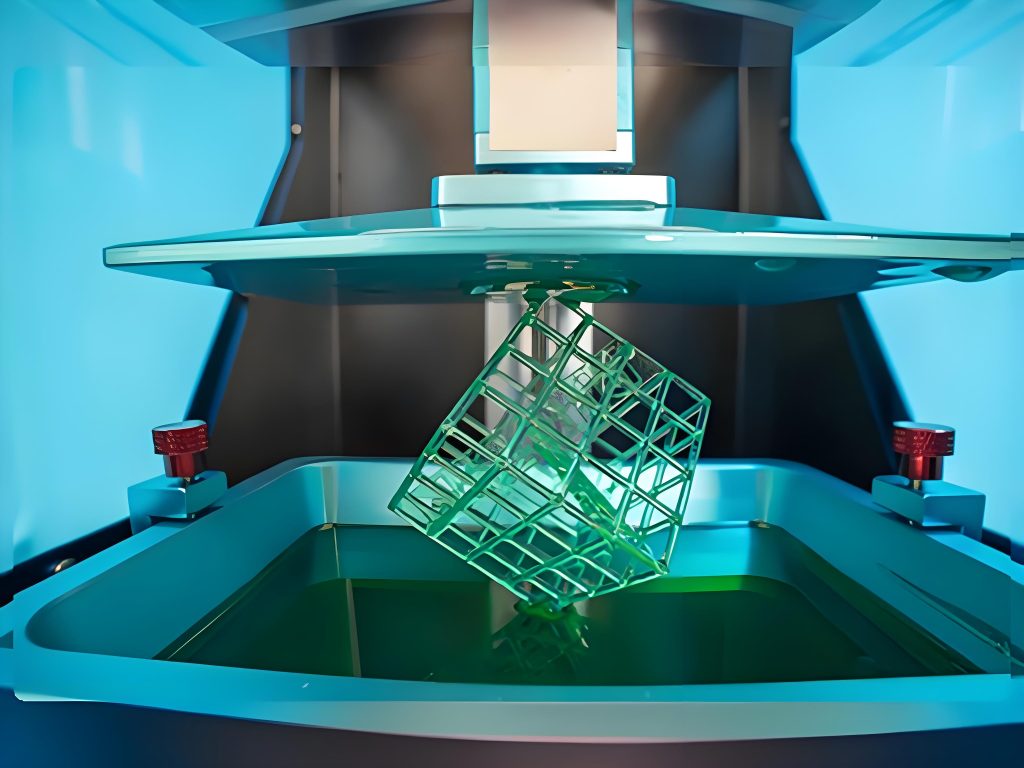

SLA (stereolithography) 3D printing

SLA (stereolithography) 3D printing is a type of additive manufacturing technology that uses a photosensitive liquid resin to create objects layer by layer. In SLA printing, a laser is used to solidify the liquid resin into a desired shape, which is then cured and hardened to create a final product. This process allows for high-resolution, detailed prints with smooth surface finishes, making it ideal for creating prototypes, jewelry, and other intricate objects.

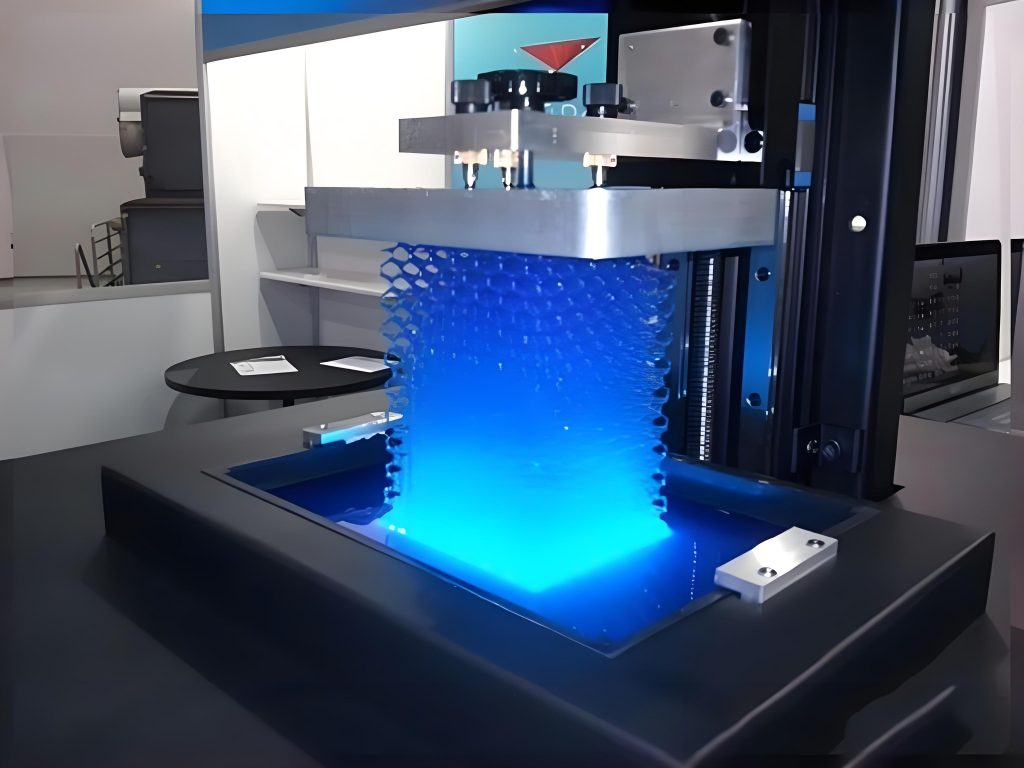

SLS (selective laser sintering) 3D printing

SLS (selective laser sintering) 3D printing is another type of additive manufacturing technology that uses a high-powered laser to selectively fuse powdered material, typically nylon or other thermoplastic powders, layer by layer to create a three-dimensional object. During the printing process, the laser sinters or fuses the powder particles together based on a digital model, gradually building up the object.

One of the key advantages of SLS printing is its ability to produce complex geometries and functional parts with high strength and heat resistance. Additionally, since the unused powder acts as support for the printed part, SLS printing does not require additional support structures, making it a more efficient process for producing intricate designs. SLS printing is commonly used in industries such as aerospace, automotive, and healthcare for prototyping, tooling, and end-use production parts.

MJF (Multi Jet Fusion) 3D printing

One of the key advantages of MJF printing is its ability to produce parts with high resolution, fine details, and excellent mechanical properties. It is also known for its speed and efficiency in producing functional prototypes, end-use parts, and complex geometries. MJF technology is popular in industries such as automotive, aerospace, and consumer goods for its ability to produce strong, lightweight parts with fast turnaround times.

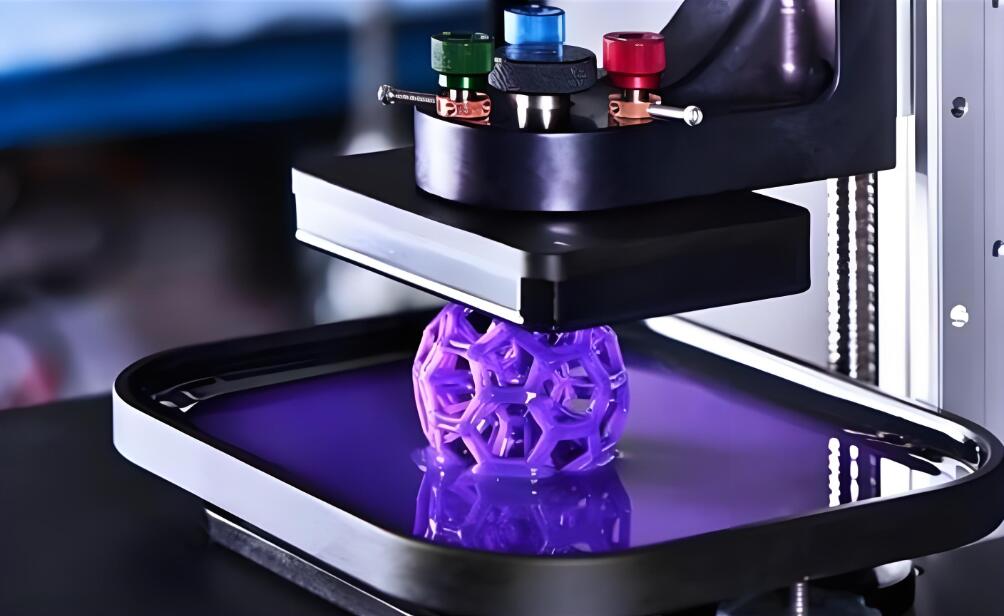

PolyJet 3D printing

PolyJet 3D printing is a type of additive manufacturing technology that uses photopolymer resin materials to create high-resolution, multi-material parts.This process allows for the creation of complex geometries, fine details, and smooth surface finishes, making it suitable for a wide range of applications in industries such as automotive, aerospace, and consumer goods. PolyJet 3D printing is known for its ability to produce parts with different colors and material properties in a single build, making it ideal for prototyping and product development.

3D Printed Parts

This is a gallery to showcase images from your recent social posts

Why choose HoFeng

At HOFeng,We have professional engineering designers, including expertise in part design, manufacturing methods, material selection, manufacturability, and designing efficient production processes.Since starting our business in 2006, we have put a lot of effort into our facilities and people to offer more competitive services than many other companies in rapid prototyping and manufacturing.

We have a 12,000 square meter production base in Dongguan and Foshan. Adhering to the quality goal of "customer satisfaction, continuous improvement," we have established a rigorous and professional quality management team and an advanced testing center with modern equipment. By upgrading the comprehensive strength of the base in research and development, manufacturing, and quality through automation, intelligence, information technology, and digitization, we are enhancing customer satisfaction in HoFeng's integrated system.

-

Quality Assurance.Our ISO 9001-certified quality management system ensures reliable All parts are dimensionally checked with calibrated equipment so that they meet your exact specifications.

-

Precision and Accuracy.Our precision machines and state-of-the-art software ensure accuracy and consistency in every product we create. Strict quality control processes guarantee that every product meets our high standards and is exactly to specification.

- Quick Response.experienced engineering and operations team Help you with instant quotations, production, and delivery In-house machine shop, 24/7hours operations, Quick turnaround High quality is our top priority

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Sheet Metal Fabrication

HOFeng’s equipped with robot CO2 welding, robot polishing, robot laser welding, laser platform welding, laser cutting machine, handheld laser welding, CNC punch machine, bending machine, automatic deburring machine to improve the speed and ability to cope with mass production applications.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development

3D Printing FAQ's

how to offer 3d printing services

If you're looking to offer 3D printing services, here are some steps you can follow to get started:

Invest in a 3D printer: Purchase a high-quality 3D printer that can cater to a variety of customer needs. Consider factors such as build volume, resolution, and material compatibility.

Offer customization: Highlight your ability to provide customized 3D prints tailored to the specific needs of your customers. This can include personalized prototypes, unique designs, and one-of-a-kind products.

Ensure quality control: Maintain high standards of quality control throughout the printing process to deliver consistent and reliable results to your customers.

Provide excellent customer service: Build strong relationships with your customers by offering excellent customer service, responding promptly to inquiries, and accommodating special requests.

By following these steps, you can establish and grow your 3D printing services business successfully.

how to price 3d printing services

Pricing 3D printing services can be a bit tricky, as there are several factors to consider. Here are some tips on how to price your 3D printing services:

Material cost: Calculate the cost of the materials used for the print, including the filament or resin. Make sure to also account for any waste material generated during the printing process.

Labor cost: Factor in the time it takes to set up and operate the 3D printer, as well as any post-processing work that may be required (such as removing support structures or sanding the print).

Overhead costs: Consider other expenses such as rent for your workspace, utilities, equipment maintenance, and any applicable taxes or fees.

Value-added services: If you offer additional services such as design assistance, file repair, or expedited turnaround times, you can consider charging extra for these services.