Fabricante de armários NEMA 6P

A Hofengfab fabrica gabinetes NEMA 6P de alta qualidade projetados para aplicações extremas onde a entrada de água, corrosão e contaminantes transportados pelo ar são preocupações. Ideais para utilização em interiores onde possa ocorrer submersão temporária ou humidade elevada, as nossas caixas com classificação 6P proporcionam um alojamento fiável para equipamentos eléctricos e electrónicos sensíveis.

Mais de 15 anos de experiência em OEM

Fabrico interno e acabamento de superfícies

Testes rigorosos de IP/NEMA e de controlo de qualidade

Documentação pronta para exportação e envio global

Caixa NEMA 6P OEM

A Hofengfab é especializada em soluções de baixo volume, alta mistura e feitas sob encomenda, oferecendo mais de 1.600 opções personalizáveis adaptadas às suas especificações exatas - incluindo altura, largura, profundidade, material, classificação e certificações. Asseguramos tempos de resposta rápidos, com amostras prontas em 7-10 dias úteis e produção em massa concluída em 15-25 dias úteis. Quer necessite de um pequeno lote ou de uma grande encomenda, cumprimos os prazos.

Especificações da caixa NEMA 6P

| Atributo | Especificação |

| Conformidade | NEMA 250 Tipo 6P, UL 50E, CSA 22.2 N.º 94 |

| Classificação IP | IP68 (submersão) |

| Submersão máxima | 1,8 m de profundidade |

| Materiais | Aço inoxidável 316L, poliéster reforçado com fibra de vidro |

| Gama de temperaturas | -40°C a 80°C (-40°F a 176°F) |

| Selos | Juntas de tripla vedação em EPDM (em conformidade com a FDA/USDA) |

caixa NEMA 6P personalizada

Quer necessite de uma dimensão não normalizada, de uma configuração com várias portas ou de recortes específicos para prensa-cabos ou ecrãs, a Hofeng fornece:

Tamanho e disposição personalizados

Recortes maquinados por CNC

Conjuntos de painéis integrados

Marcação (logótipo a laser, correspondência de cores, etiquetas de série)

Serviço único de conceção, moldagem e moldagem por injeção.

Serviços de fabrico personalizado

Especializada no processamento de chapas metálicas de precisão, incluindo dobragem, corte a laser, soldadura por escovagem, polimento, estampagem e muito mais.

Entrega atempada.

A criação de protótipos é normalmente concluída em 10 dias.

O prazo de produção normal é de cerca de 15 dias, consoante a quantidade e a complexidade do produto.

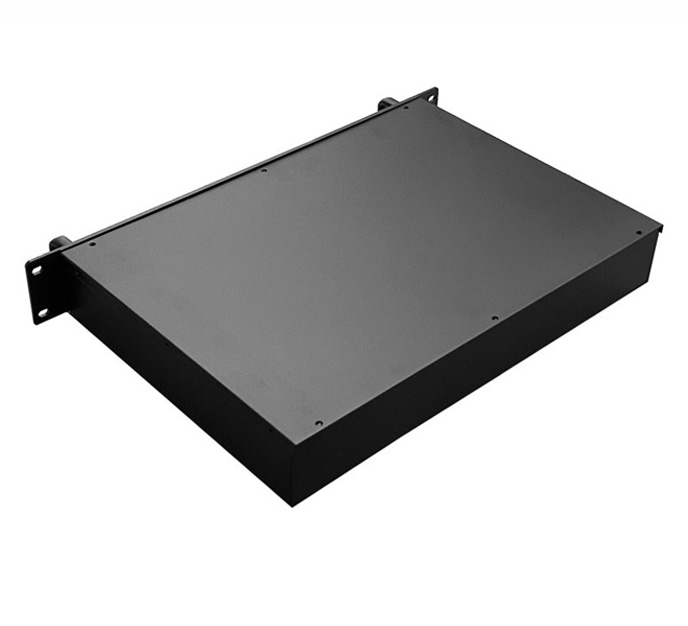

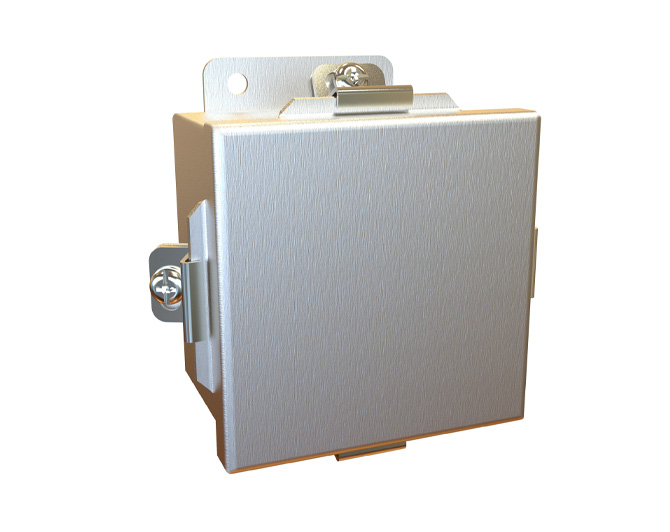

Produtos relacionados

Servimos indústrias que incluem automação industrial, sistemas de telecomunicações/rackmount, energia renovável, equipamento médico e aplicações militares/aeroespaciais - fornecendo soluções de alojamento robustas e específicas para aplicações, concebidas para fiabilidade.

FAQ

Qual é a diferença entre NEMA 6P e NEMA 6?

O NEMA 6P oferece proteção adicional contra a corrosão e destina-se a períodos mais longos de submersãoAo contrário da NEMA 6, que se destina apenas a imersão temporária.

Posso utilizar armários NEMA 6P no exterior?

São principalmente classificados para utilização em interioresmas pode ser adaptado a ambientes exteriores protegidos com revestimentos e drenagem adequados.

O Hofengfab oferece armários NEMA 6P com rótulo UL?

Sim, a certificação UL 508A está disponível mediante pedido para projectos elegíveis.

O que é um armário NEMA 6P?

A Caixa NEMA 6P é um tipo de invólucro elétrico classificado para utilização em interioresque oferece proteção contra poeira, corrosão e submersão prolongada em água. É normalmente utilizado em ambientes onde humidade e exposição a produtos químicos como as estações de tratamento de água, os sistemas marinhos e as instalações de transformação de alimentos.

Qual é a diferença entre NEMA 6 e NEMA 6P?

Embora tanto o NEMA 6 como o 6P sejam concebidos para submersão ocasionalo "P" em 6P indica maior proteção contra a corrosão. Os armários NEMA 6P são mais adequados para submersão prolongada ou repetida e ambientes químicos agressivos.

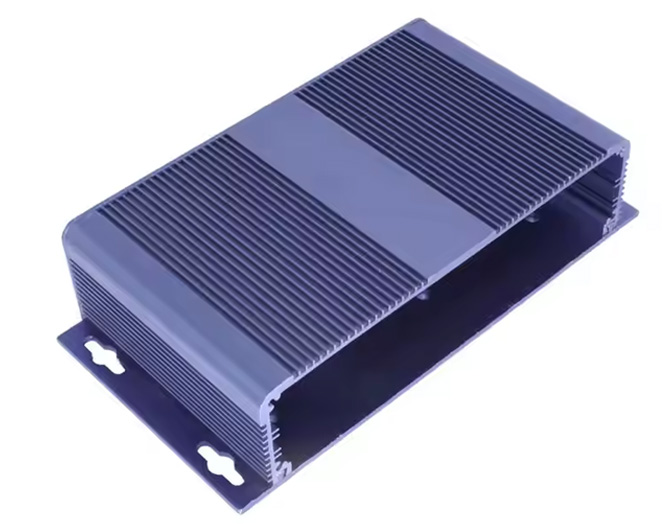

Que materiais são normalmente utilizados nos armários NEMA 6P?

Na HofengFfab, oferecemos armários NEMA 6P em:

Aço inoxidável 304 ou 316 (resistente à corrosão)

Aço laminado a frio com revestimento em pó

Alumínio para aplicações ligeiras

Cada material é selecionado com base no ambiente alvo e na exposição à corrosão.

Posso personalizar um armário NEMA 6P?

Sim. O Hofengfab fornece serviços completos OEM/ODM, incluindo:

Tamanhos e dimensões personalizados

Recortes para condutas ou ecrãs

Acessórios de montagem

Gravação do logótipo ou revestimento a pó (cores RAL)

Como posso garantir que o armário cumpre as normas NEMA 6P?

Todos os nossos recintos são submetidos a ensaios de vedação, corrosão e entrada de água. A pedido, fornecemos relatórios de ensaio, desenhose documentação de certificação de terceiros para garantir a conformidade.