Serviço de corte a laser para fabrico OEM

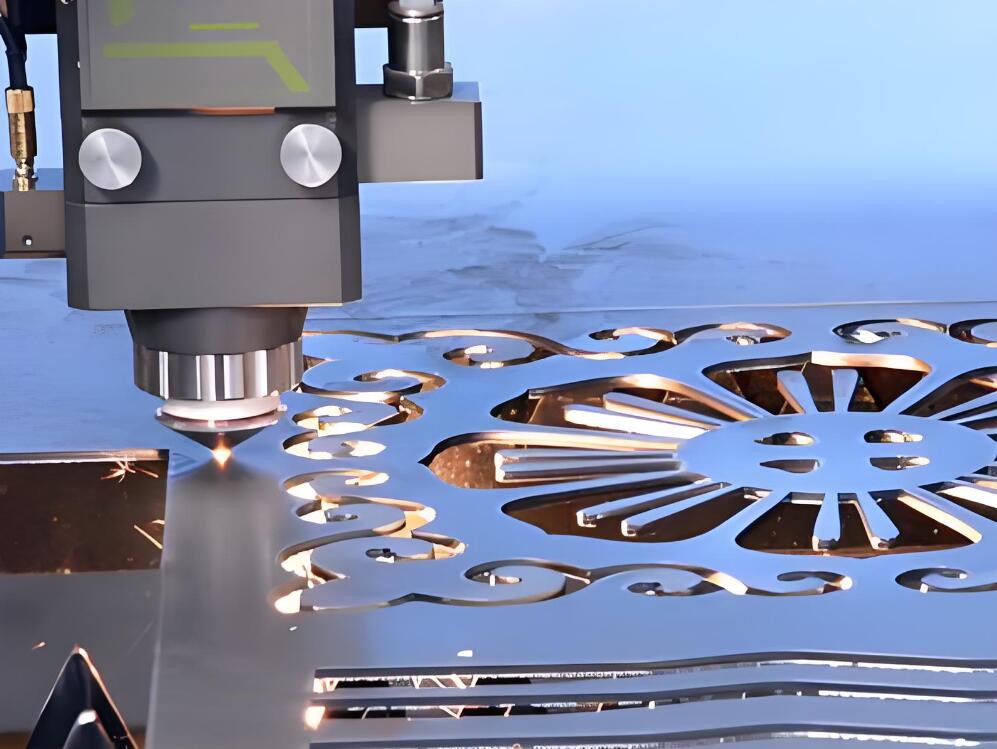

A nossa tecnologia laser de ponta garante precisão e qualidade em cada corte, tornando-a adequada para várias aplicações, quer se trate de cortar formas complexas, obter tolerâncias precisas ou trabalhar com materiais únicos.

Serviço de corte a laser para fabrico OEM prats de chapa metálica

A Hofengfab orgulha-se de apresentar o seu serviço de corte a laser personalizado em linha, que abrange uma vasta gama de materiais, incluindo metais, plásticos, borracha, espuma e madeira. A nossa tecnologia laser de ponta garante precisão e qualidade em cada corte, tornando-a adequada para várias aplicações, quer se trate de cortar formas complexas, obter tolerâncias precisas ou trabalhar com materiais únicos.

Com as nossas amplas capacidades, podemos lidar com uma vasta gama de materiais, abrangendo vários tipos de metais, plásticos (incluindo acrílico), borracha, espuma e madeira. Esta versatilidade permite-nos satisfazer uma vasta gama de necessidades dos clientes, desde a produção de um único protótipo até à produção de baixo volume, de lotes e mesmo de grandes volumes.Peças cortadas a laser de alta qualidade em poucos dias

serviço de corte a laser:

Serviço de corte a laser de metais

Serviço de corte a laser de plástico

Serviço de corte a laser de acrílico

Serviço de corte a laser de madeira

Alternativas ao corte a laser

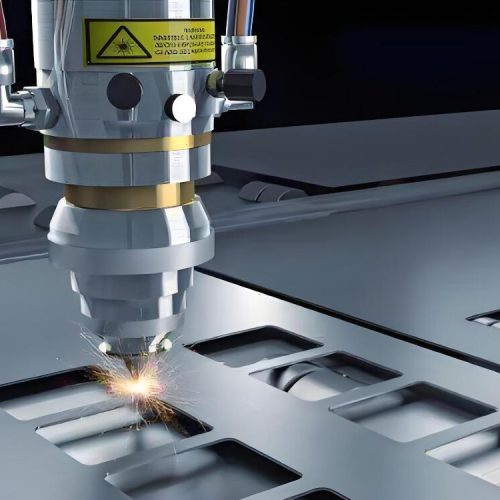

Existem muitos tipos de máquinas de corte a laser. De acordo com diferentes métodos de classificação, existem os seguintes tipos.

De acordo com o tamanho da máquina de corte a laser, esta pode ser dividida em máquina de corte a laser de grandes dimensões, máquina de corte a laser de secretária e máquina de corte a laser de secretária.

De acordo com as diferentes tecnologias laser, pode ser dividida em máquina de corte a laser YAG (máquina de corte a laser de cristal), máquina de corte a laser Nd, máquina de corte a laser CO2, etc.

De acordo com os diferentes materiais de corte, pode ser dividida em máquina de corte a laser de metal e máquina de corte a laser não-metal.

De acordo com os diferentes campos de aplicação, pode ser dividida em máquina de corte a laser industrial e máquina de corte a laser educacional, etc.

Tipos de cortadores a laser disponíveis na HOFeng:

Máquinas de corte a laser C02

Máquinas de corte a laser Nd

Máquinas de corte a laser Nd:Yag

Vantagens e desvantagens do corte a laser CNC

Vantagens

Acessibilidade// A velocidade de corte é rápida, o que permite realizar métodos de corte como o corte rápido e o corte relâmpago.

Esta combinação de velocidade e qualidade garante que podemos fornecer peças metálicas fabricadas com precisão a um preço muito competitivo.

Qualidade de corte// O corte a laser produz peças intrincadas e complexas com acabamentos de borda de alta qualidade sem a necessidade de operações de acabamento adicionais, como retificação ou rebarbação. e todos são formados.

Seleção de materiais// Pode cortar eficazmente chapas metálicas de vários materiais, tais como aço carbono, aço inoxidável, alumínio, ligas, metais não ferrosos, etc.

Tolerâncias apertadas// O corte a laser tem uma elevada precisão dimensional e pode cortar ângulos obtusos e costuras estreitas, garantindo precisão e exatidão em todo o processo de fabrico de chapas metálicas.

Desvantagens

O corte a laser está, de facto, limitado a chapas e tubos de espessura média e pequena, principalmente devido à física do feixe laser e à interação do material com o mesmo. À medida que a espessura da peça de trabalho aumenta, a capacidade do feixe laser para penetrar e cortar através do material diminui, resultando numa diminuição da velocidade de corte. Esta limitação é inerente ao processo de corte a laser e tem de ser tida em conta quando se planeiam peças de trabalho maiores ou mais espessas.

As nossas outras capacidades de fabrico

Somos especializados em impressão 3D, maquinagem CNC, fundição a vácuo, moldagem por injeção e fabrico de chapas metálicas, oferecendo uma grande variedade de materiais e acabamentos de superfície.

Serviços de moldagem por injeção

A HOFeng pode moldar qualquer termoplástico. Serviços de moldagem por injeção rentáveis para os seus produtos e peças personalizados. Ferramenta de protótipo em apenas 10 dias Ferramenta de produção em apenas 2 semanas, ISO 9001:2015 | Crítico para as inspecções de qualidade

Serviço de impressão 3D

O serviço de impressão 3D da HOFeng é o seu centro de produção de fabricação aditiva para mais de 30 materiais para qualquer aplicação, serviço de impressão 3D Somos especialistas em impressão 3D para atender a todos os seus requisitos de nível industrial.

Serviços de fundição de uretano

A nossa certificação ISO 9001 permite-nos oferecer uma qualidade de topo em cada lote. Somos os especialistas em materiais de poliuretano para o desenvolvimento do seu produto

Você pergunta, nós respondemos

Serviços de fabrico de chapa metálica

A prototipagem de chapa metálica pode acelerar o desenvolvimento do seu projeto com as suas iterações de design rápidas, flexíveis e fiáveis, funcionalidade de teste e passagem do conceito ao mercado com rapidez.