Serviços de fabrico de protótipos de chapa metálica

A HOFeng pode ajudá-lo a fabricar rapidamente e com precisão as suas caixas, suportes, conjuntos, soldaduras, armários, caixas e outras peças e protótipos em chapa metálica

SEM MOQ (quantidade mínima de encomenda)

Inspeção 100% para cada peça

Os ficheiros que carregar são estritamente confidenciais e seguros

Aplicações para o fabrico de chapas metálicas

Temos mais de 60 máquinas CNC na nossa fábrica

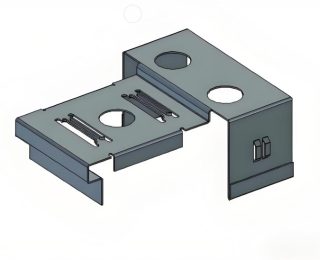

Protótipos de chapa metálica

Protótipos de chapa metálica

Se precisa de um

suporte, chassis

recinto, ou qualquer outro

chapas metálicas complexas

conceção, podemos satisfazer as suas necessidades

Produtos de chapa metálica

Produtos de chapa metálica

A nossa produção de baixo volume

pode produzir até

60 a 1500 + chapa metálica

peças num prazo de 10 dias.

Conjuntos de várias peças

Com a nossa equipa experiente e protocolos de qualidade rígidos, podemos garantir que a Sheet Metal Products entregará um produto acabado em conformidade à primeira vez.

Materiais de prototipagem de chapa metálica-Fabricação de chapa metálica China

Como fabricante líder de chapas metálicas na China, a HOFeng tem 15 anos de experiência no fabrico de chapas metálicas, ajudando-o a fornecer produtos metálicos de precisão de alta qualidade a preços competitivos. A HOFeng oferece uma variedade de materiais de fabrico de chapas metálicas, incluindo aço inoxidável, alumínio, cobre, latão e aço galvanizado, e podemos ajudar os clientes a escolher o mais adequado para os seus projectos de prototipagem.

o que é a prototipagem de chapa metálica

O processamento de chapas metálicas é um método de conformação a frio e a quente, montagem e ligação de chapas, perfis e tubos metálicos para fabricar componentes metálicos por soldadura, rebitagem e aparafusamento. Envolve principalmente trabalho de bancada, estampagem, corte de metal, soldadura, tratamento térmico, tratamento de superfície, rebitagem, montagem e outros tipos de trabalho profissional.

Capacidades abrangentes de prototipagem da HOFeng

A nossa fábrica cobre uma área de 6.000 metros quadrados, com instalações completas de hardware e software, incluindo mais de 60 máquinas de perfuração, 30 centros de maquinação CNC, 3 máquinas de corte a laser e várias máquinas de dobragem CNC. A empresa está equipada com muitos designers experientes em desenvolvimento de moldes de precisão e programação CNC, e todos os produtos estão em conformidade com os padrões da diretiva ROHS. Nossas máquinas podem remover eficientemente rebarbas e bordas afiadas, retificação de precisão, lixamento de correia larga, aumentando a segurança e a estética de seus componentes de chapa metálica, garantindo que seus produtos de chapa metálica atendam aos mais altos padrões.

Além disso, oferecemos uma variedade de acabamentos, incluindo revestimento em pó, galvanização e anodização. Também oferecemos corte a laser dedicado,

Serviços de corte por jato de água, EDM de fio, gravação fotoquímica, perfuração e moldagem. A nossa equipa de engenheiros e técnicos especializados dedica-se a fornecer aos nossos clientes peças da mais alta qualidade e um excelente serviço ao cliente. Quer necessite de alguns protótipos ou de uma produção de baixo volume, somos o seu balcão único para todas as suas necessidades de fabrico de chapas metálicas. Contacte-nos hoje para obter um orçamento gratuito!

Processo de acabamento de chapas metálicas

1. acabamento padrão

Retificação e polimento

Escovagem

2. Jato de esferas

3. Anodização

Anodização (tipo II ou tipo III)

Cromato

Zinco

Passivar

Níquel eletrolítico

Lata

A classe 1 refere-se a não tingidos e a classe 2 refere-se a tingidos

revestimentos. Embora o preto seja o tipo 2 mais popular

anodização, existem transparente, azul, vermelho, dourado, amarelo,

laranja, verde, roxo,

e outros pigmentos disponíveis.

A classe 1 refere-se a um revestimento duro transparente, enquanto a classe 2 se refere a

um pelo duro preto.

4. Revestimento químico por película

5. revestimento em pó

6. RevestimentoAs opções de revestimento podem proporcionar resistência à corrosão, melhorar as propriedades de desgaste e ajudar na condutividade, ao mesmo tempo que melhoram o aspeto com um acabamento uniforme e de qualidade.

As opções de revestimento disponíveis incluem:

Anodização (tipo II ou tipo III)

Cromato

Zinco

Passivar

Níquel eletrolítico

Lata

7. Rastreio de seda

Este processo é frequentemente utilizado para adicionar etiquetas, instruções ou padrões decorativos a produtos metálicos fabricados.

8. Shot Peening 9 Montagem e preparação de kits

As nossas outras capacidades de fabrico

Somos especializados em impressão 3D, maquinagem CNC, fundição a vácuo, moldagem por injeção e fabrico de chapas metálicas, oferecendo uma grande variedade de materiais e acabamentos de superfície.

Maquinação CNC

Dispomos de um centro de maquinagem composto por fresagem-torneamento, 3 eixos standard, 5 eixos contínuos, fresadora de 3+2 eixos, perfuração e pós-processamento utilizando mais de 50 metais e plásticos diferentes, disponíveis em mais de 15 acabamentos de superfície. Tolerâncias até ±.0000394" (0.001mm )

Serviços de moldagem por injeção

A HOFeng pode moldar qualquer termoplástico. Serviços de moldagem por injeção rentáveis para os seus produtos e peças personalizados. Ferramenta de protótipo em apenas 10 dias Ferramenta de produção em apenas 2 semanas, ISO 9001:2015 | Crítico para as inspecções de qualidade

Serviço de impressão 3D

O serviço de impressão 3D da HOFeng é o seu centro de produção de fabricação aditiva para mais de 30 materiais para qualquer aplicação, serviço de impressão 3D Somos especialistas em impressão 3D para atender a todos os seus requisitos de nível industrial.

Serviços de fundição de uretano

A nossa certificação ISO 9001 permite-nos oferecer uma qualidade de topo em cada lote. Somos os especialistas em materiais de poliuretano para o desenvolvimento do seu produto

Você pergunta, nós respondemos

Serviços de fabrico de chapa metálica

A prototipagem de chapa metálica pode acelerar o desenvolvimento do seu projeto com as suas iterações de design rápidas, flexíveis e fiáveis, funcionalidade de teste e passagem do conceito ao mercado com rapidez.