Cotação mais rápida através do carregamento de dados 3D

Corte e conformação de metais

- Acomodar a dobragem complexa e o processamento a laser de formas especiais

- Adapta-se a vários materiais e tratamentos de superfície Entrega mais rápida em 1 dia, mesmo para 1 peça

Os ficheiros que carregar são estritamente confidenciais e seguros

Serviço de corte e conformação de metais

Trabalhar com vários métodos de processamento e formas especiais, tais como corte a laser, perfuração e encaixe CNC, dobragem e pulverização.

Trabalhar com vários métodos de processamento e formas especiais, tais como corte a laser, perfuração e encaixe CNC, dobragem e pulverização.

Trabalhar com vários materiais, tais como aço inoxidável, aço-carbono e ligas de alumínio.

Capaz de identificar automaticamente os tipos de furos.

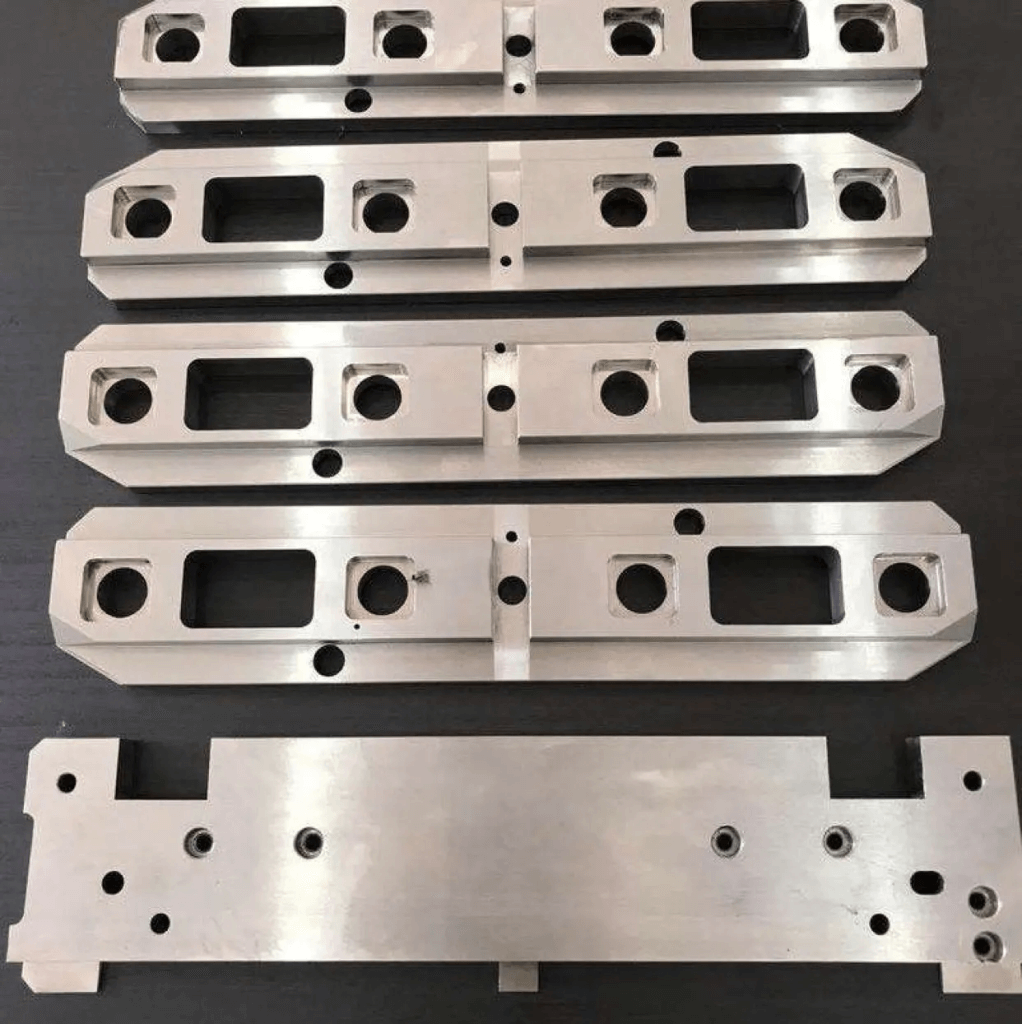

Capacidades de fabrico de chapa metálica

A HOFeng está equipada com robô de soldadura CO2, robô de polimento, robô de soldadura a laser, plataforma de soldadura a laser, máquina de corte a laser, máquina de soldadura a laser portátil, máquina de perfuração CNC, máquina de dobragem, máquina de rebarbação automática para melhorar a velocidade e a capacidade de lidar com aplicações de produção em massa.

grandes fabricantes de chapas metálicas

Processamento de chapas de chassis e armários em chapa metálica

Décadas de experiência em fabricação de chapas metálicas

Se procura um fabricante de chapas metálicas que possa lidar com tudo, desde o desenvolvimento de novos produtos e peças de protótipos a grandes séries de produção e serviços de montagem, a HOFeng está um passo acima do que espera. Os nossos especialistas gerem todas as etapas do processo, desde a assistência ao design e o fabrico de metal até à pintura, serigrafia, kits e montagem.

Puncionamento CNC

As nossas prensas de puncionamento CNC podem processar com precisão caraterísticas padrão e formas complexas em chapa metálica para satisfazer os seus requisitos. O punção de torre que utilizamos pode perfurar até uma espessura de 1/4 de polegada e também podemos produzir caraterísticas especiais, tais como escareadores, contas e persianas.

dobragem de chapa

ISO9001

Prazo de entrega tão rápido quanto um dia

Alumínio, aço, aço inoxidável e muito mais

A máquina de dobragem de chapa metálica é utilizada principalmente para dobrar a chapa em linha reta. O processo de dobragem por pressão é utilizado principalmente para o processamento de peças com grandes lotes de produção, formas complexas e requisitos de alta precisão.

Forneça ângulos precisos com os nossos serviços de dobragem, obtendo um produto final que se enquadra em tolerâncias apertadas.

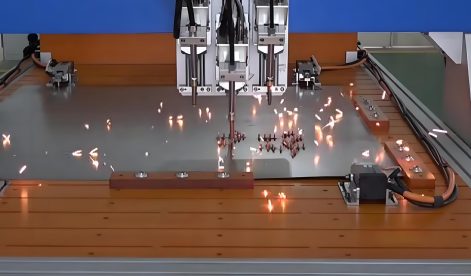

serviço de corte a laser fabrico de chapas metálicas

O corte a laser utiliza um laser potente que é intensificado através de lentes ou espelhos. É uma máquina precisa e eficiente em termos energéticos, adequada para chapas metálicas finas ou de calibre médio, mas pode ter dificuldade em penetrar nos materiais mais duros.

Corte por jato de água

O corte por jato de água é um método de fabrico de chapas metálicas que utiliza um jato de água de alta pressão (misturado com uma substância abrasiva) para cortar metal. O serviço de corte a jato de água da HOFeng é uma solução versátil e econômica para peças de metal de precisão cortadas com um alto grau de precisão. Nossas máquinas de jato de água de grande formato podem cortar materiais de até 6 polegadas de espessura com uma tolerância de 0,005 ″ - 0,015 ″.

Corte por plasma CNC

O corte por plasma é mais eficaz no corte de metais não ferrosos (aço inoxidável, alumínio, cobre, titânio, níquel); a sua principal vantagem é que, ao cortar metais de pequena espessura, a velocidade de corte por plasma é rápida, especialmente no corte de chapas finas de aço carbono comum. O serviço de corte por plasma da HOFeng pode fornecer peças complexas de alta precisão em materiais como alumínio, aço e aço inoxidável.

EDM de fio e de funil

A EDM por afundamento envolve a utilização de descargas eléctricas para desgastar a superfície da peça de trabalho e criar as formas pretendidas. Por outro lado, a EDM de fio utiliza um fio fino para cortar a peça de trabalho, adequado para maquinagem de alta precisão e de formas complexas. Ajuda os requisitos de alta precisão no fabrico de peças e melhora a eficiência da produção.

Variedade de métodos de soldadura

A HOFeng dispõe de quatro técnicas de soldadura principais: TIG (gás inerte de tungsténio), MIG (gás inerte de metal), MAG (gás ativo de metal) e soldadura de CO2. Cada um destes métodos oferece vantagens únicas e é adequado para diferentes aplicações de soldadura, desde a soldadura de precisão ao fabrico de trabalhos pesados.

Acabamento de superfícies e montagem

O "acabamento de superfícies" refere-se aos processos utilizados para melhorar o aspeto, a durabilidade da superfície e a resistência à corrosão de um produto. Estas opções de acabamento incluem o revestimento em pó, a anodização, o revestimento, o polimento, a escovagem e muito mais. O acabamento de superfícies é essencial para melhorar a qualidade geral e a estética do produto final, bem como para o proteger de factores ambientais como a ferrugem e a corrosão.

Os "Processos secundários" referem-se a operações ou serviços adicionais que podem ser necessários após a conclusão do processo de fabrico inicial. Estes processos secundários podem incluir actividades como a dobragem CNC, a retificação, a roscagem, a serrilha e muito mais. Estes serviços são essenciais para alcançar as especificações do produto final e os padrões de qualidade desejados.

Materiais de fabrico de metais

As nossas outras capacidades de fabrico

Somos especializados em impressão 3D, maquinagem CNC, fundição a vácuo, moldagem por injeção e fabrico de chapas metálicas, oferecendo uma grande variedade de materiais e acabamentos de superfície.

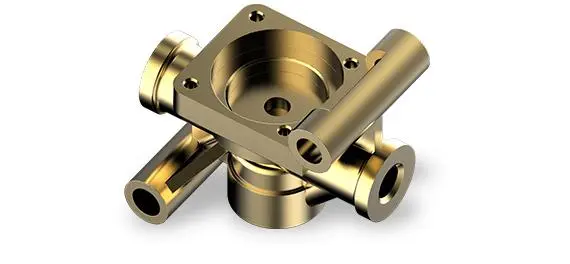

Maquinação CNC

Dispomos de um centro de maquinagem composto por fresagem-torneamento, 3 eixos standard, 5 eixos contínuos, fresadora de 3+2 eixos, perfuração e pós-processamento utilizando mais de 50 metais e plásticos diferentes, disponíveis em mais de 15 acabamentos de superfície. Tolerâncias até ±.0000394" (0.001mm )

Serviços de moldagem por injeção

A HOFeng pode moldar qualquer termoplástico. Serviços de moldagem por injeção rentáveis para os seus produtos e peças personalizados. Ferramenta de protótipo em apenas 10 dias Ferramenta de produção em apenas 2 semanas, ISO 9001:2015 | Crítico para as inspecções de qualidade

Serviço de impressão 3D

O serviço de impressão 3D da HOFeng é o seu centro de produção de fabricação aditiva para mais de 30 materiais para qualquer aplicação, serviço de impressão 3D Somos especialistas em impressão 3D para atender a todos os seus requisitos de nível industrial.

Serviços de fundição de uretano

A nossa certificação ISO 9001 permite-nos oferecer uma qualidade de topo em cada lote. Somos os especialistas em materiais de poliuretano para o desenvolvimento do seu produto

Porquê escolher a HoFeng

Precisão e exatidão

1. As nossas máquinas de precisão e o software de última geração garantem a exatidão e a consistência de cada produto que criamos.

2. Processos rigorosos de controlo de qualidade garantem que cada produto cumpre os nossos elevados padrões e está exatamente de acordo com as especificações.

Resposta rápida

1. Equipa de engenharia e operações com experiência

2. Oficina mecânica interna, funcionamento 24 horas por dia, 7 dias por semana

3. A alta qualidade é a nossa principal prioridade

4. Ajudamo-lo com orçamentos imediatos, produção e entrega

Garantia de qualidade

1. O nosso sistema de gestão da qualidade com certificação ISO 9001 garante uma

2. Todas as peças são verificadas dimensionalmente com equipamento calibrado, de modo a corresponderem às suas especificações exactas.

3.250+Projectos Entregues por mês,10000+SQ ÁREA DO MEDIDOR, 15+ ANOS DE SERVIÇO