What Is a NEMA 2 Enclosure?

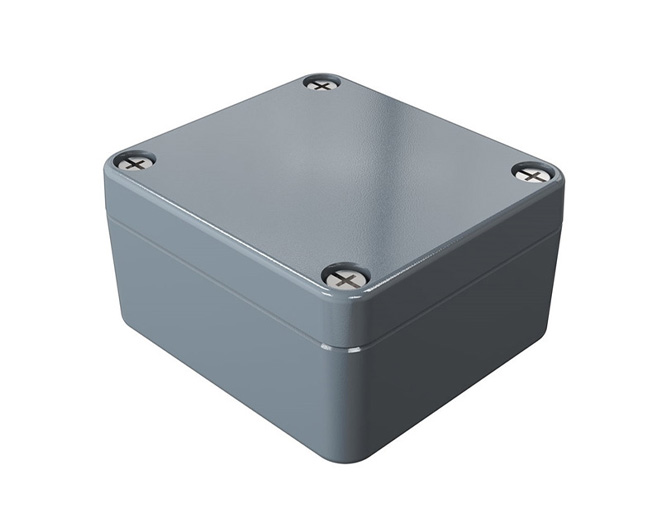

NEMA 2 enclosures are designed for indoor use, offering protection against light drips, splashing water, and limited dust ingress. NEMA 2 enclosures are a step up from NEMA 1 enclosures because they provide protection from liquids that NEMA 1 enclosures don’t offer. They provide this protection through durable design that helps the enclosures shed liquids from their surface and keeps them tightly sealed against dirt.

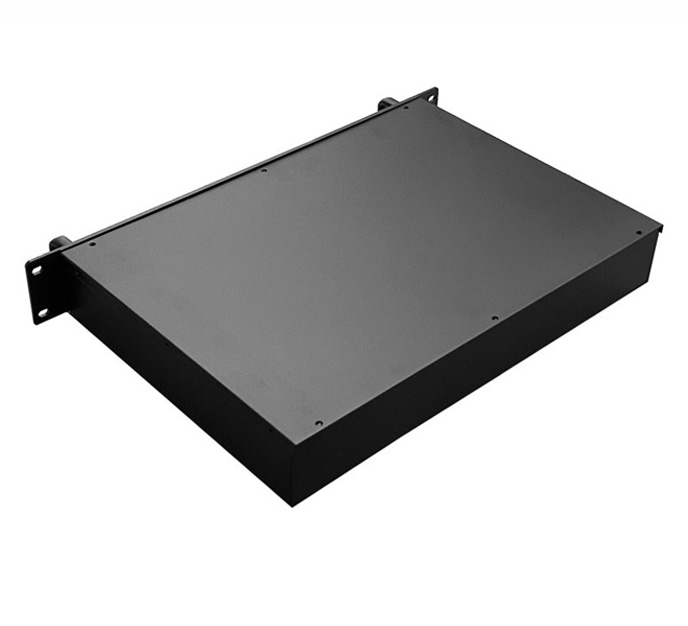

aluminum electrical enclosure manufacturer

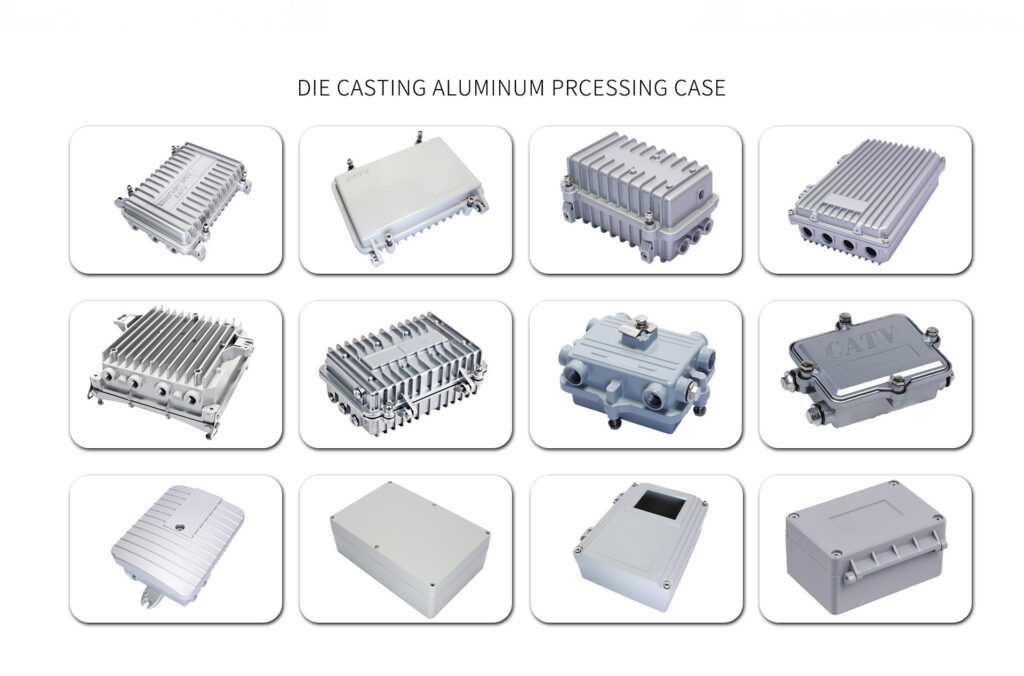

Hofengfab specializes in low-volume, high-mix, made-to-order solutions, offering over 1,600 customizable options tailored to your exact specifications—including height, width, depth, material, rating, and certifications. We ensure fast turnaround times, with samples ready in 7–10 working days and mass production completed within 15–25 working days. Whether you need a small batch or a large order, we deliver on time.

Why Choose NEMA 2 Enclosure?

Based on over a decade of enclosure manufacturing experience, we’ve seen how incorrect enclosure selection leads to costly downtime. For instance:

Case Example: A manufacturing client in Ohio experienced repeated relay failures due to high ambient humidity and light condensate near their electrical panels. After switching from NEMA 1 to NEMA 2 enclosures, failure incidents dropped by 90% within 3 months, saving over $12,000 in repair and loss costs.

Compliance & Standards

All our NEMA 2 enclosures are manufactured in accordance with:

UL 50 / 50E certification

NEMA 250 standards

ISO 9001:2015 quality management systems

Optional RoHS and CE markings for international markets

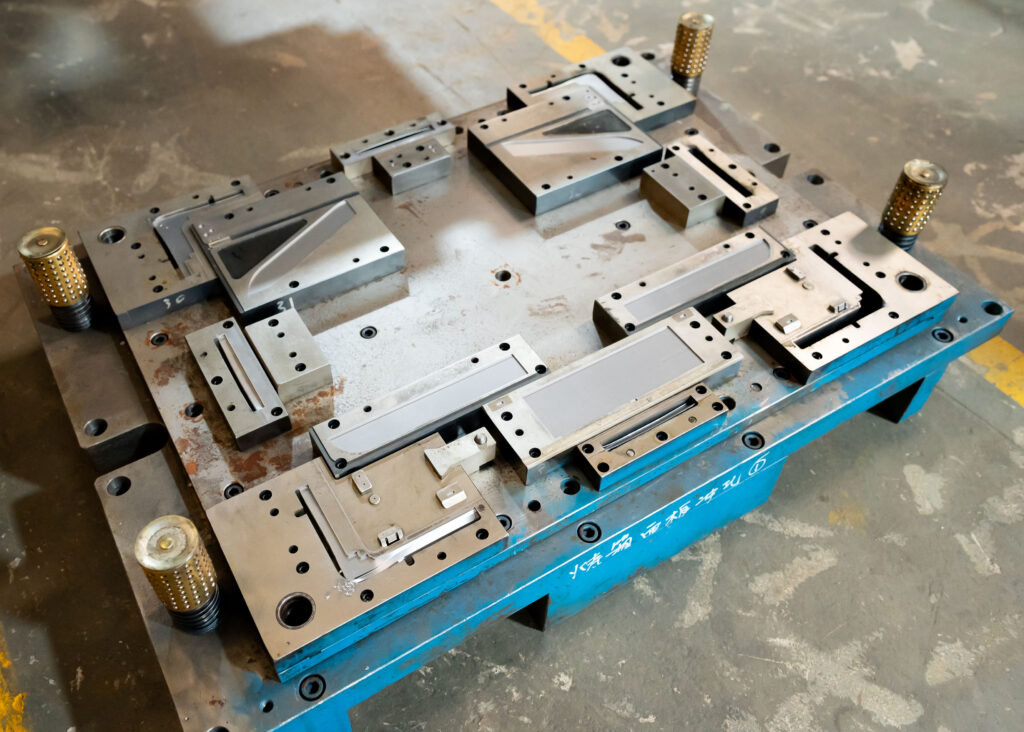

One-stop service for design, molding, and injection molding.

Custom Fabrication Services

Specializing in precision sheet metal processing, including bending, laser cutting, brushed welding, polishing, stamping, and more.

ON-Time Delivery.

Prototyping typically completed within 15 days.

Standard production lead time is around 15 days, depending on product quantity and complexity.

Related Products

We serve industries including industrial automation, telecom/rackmount systems, renewable energy, medical equipment, and military/aerospace applications - delivering robust, application-specific housing solutions engineered for reliability.

FAQ

What does a NEMA 2 enclosure protect against?

NEMA 2 enclosures are designed for indoor use, offering protection against limited amounts of falling water (like dripping or splashing) and light levels of dust. They are suitable for locations with moderate humidity, such as mechanical rooms, basements, or near industrial washdown areas (non-direct).

How is NEMA 2 different from NEMA 1 or NEMA 4?

NEMA 1 provides only basic protection against contact and dust.

NEMA 2 adds drip protection, making it better suited for damp environments.

NEMA 4 is fully waterproof and suitable for outdoor or washdown environments.

If your application is indoors with occasional moisture exposure but doesn’t require full waterproofing, NEMA 2 is a cost-effective middle ground.

Can I use a NEMA 2 enclosure outdoors?

No. NEMA 2 enclosures are not rated for outdoor use. They lack protection against rain, windblown dust, and UV exposure. For outdoor environments, consider NEMA 3, 3R, or 4/4X enclosures depending on your specific requirements.

Are NEMA 2 enclosures waterproof?

Not exactly. They are drip-tight, meaning they can resist vertically falling water or light splashes, but they are not sealed against high-pressure water, heavy condensation, or immersion. For true waterproofing, you’ll need NEMA 4 or 6-rated enclosures.

What materials are typically used for NEMA 2 enclosures?

Most NEMA 2 enclosures are made from:

Powder-coated cold-rolled steel (most common for dry environments)

Stainless steel (for mildly corrosive or humid interiors like food processing zones)

The material choice depends on your environmental exposure, aesthetics, and durability needs.

Are NEMA 2 enclosures UL certified?

Yes, reputable manufacturers provide UL 50 / 50E listed NEMA 2 enclosures. Always check for UL labeling if third-party certification is required by your application or jurisdiction.

What types of equipment are housed in NEMA 2 enclosures?

They are commonly used to protect:

Control panels

Terminal blocks

Power distribution units

HVAC or lighting system controls

…in indoor commercial or light industrial environments.

Do NEMA 2 enclosures have gaskets?

Yes. A drip-tight neoprene or EPDM gasket is typically fitted between the enclosure body and door to seal out moisture and dust. Regular inspection and replacement of gaskets is recommended for long-term performance.