Solutions for the oil and gas industry

- Perfectly matched with precision valves, bushings, and sensors to improve the efficiency of energy infrastructure operation.

Supporting energy precision component manufacturing services

HOFeng has several years of experience in precision parts manufacturing and processing. With mature industrial design and processing processes, as well as various CNC machine tools and equipment, it can manufacture precision parts in combination.

Energy equipment relies on high-precision accessories

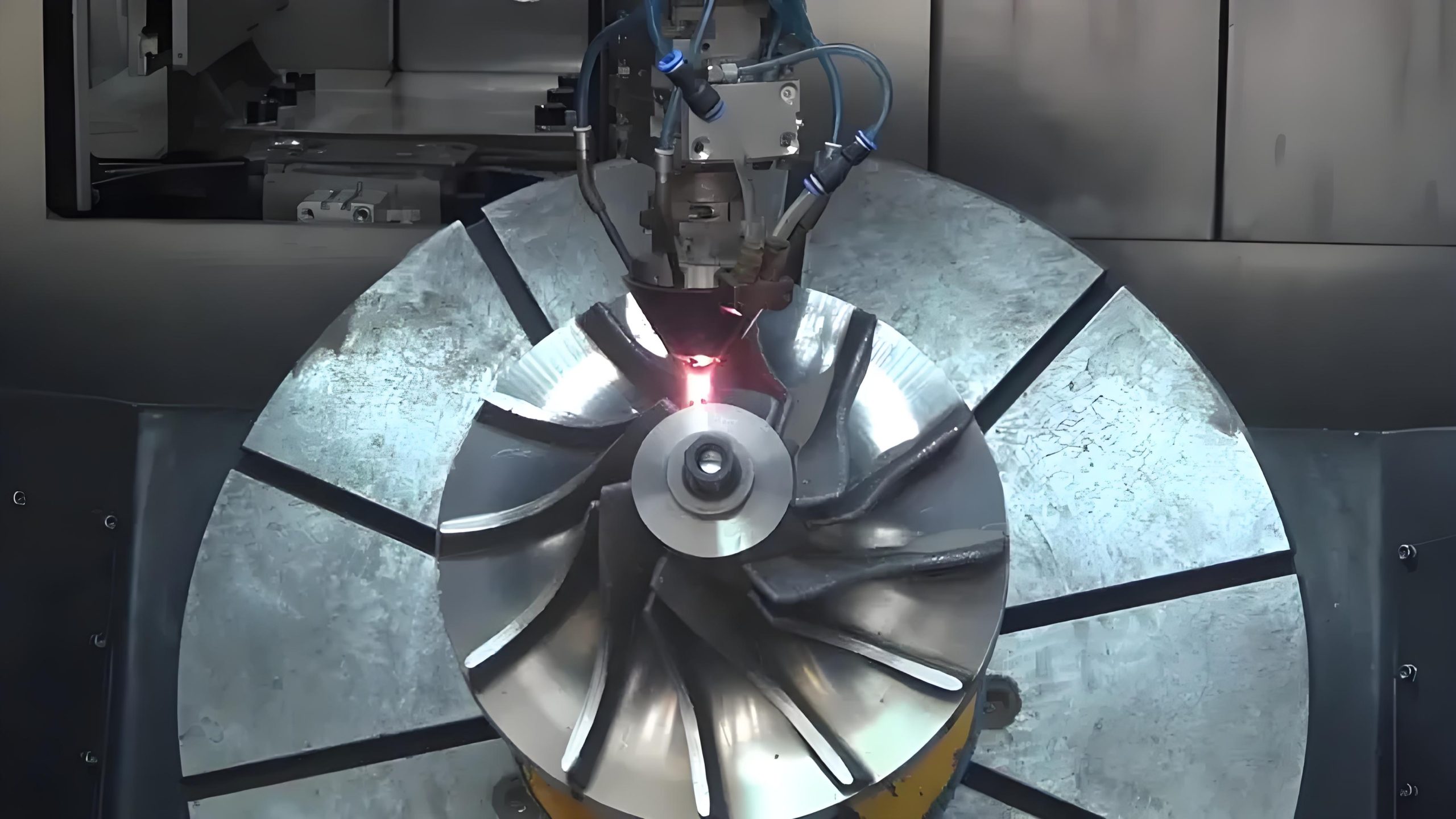

The natural gas, oil, and energy industries rely on many CNC machined parts, and precision valves, bushings, and sensor equipment all require precision machined parts. In order to maintain the efficient operation of important energy infrastructure, components need to be perfectly coordinated. Parts used in harsh environments require high precision, as well as high corrosion and heat resistance, and these metals typically require modern CNC cutting tools.

Hybrid manufacturing technology

In the field of precision parts manufacturing, HOFeng has mastered hybrid manufacturing technology and is able to produce more precise and high-quality components at lower costs and faster. It has great advantages in manufacturing various precision parts and combining supporting equipment.

The advantages of hybrid manufacturing technology

In addition to being able to produce more precise and high-quality parts faster, hybrid manufacturing technology also has several advantages

- Improve productivity and accelerate production speed

- Achieve higher accuracy and stricter tolerances

- Improve mechanical performance and save costs

- Reduce upfront investment and operating costs

- Significantly reduce manufacturing time

Disadvantages of hybrid manufacturing technology

- High initial equipment investment in hybrid manufacturing

- Mixed manufacturing requires high operator requirements

HOFeng helps enterprises in need of manufacturing precision parts by providing integrated services from design to finished products through existing equipment and skilled operators.

Manufacturing of precision parts for energy equipment

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development