Manufacturing and Solutions for Electric Vehicles

- Various parts used in automobiles, including exterior parts and customized gear solutions

Electric vehicle parts processing and gear manufacturing services

HOFeng has been deeply involved in the field of automotive parts for many years, with comprehensive design, processing, and assembly capabilities. It can provide "one-stop" services and provide the best solutions for electric vehicle manufacturing enterprise customers.

Customized processing of electric vehicle parts

HOFeng has a complete industrial process for customized processing of automotive parts. Whether it is traditional cars or electric cars, the customization and processing of automotive parts are very mature, and it has the ability to solve various needs for customers.

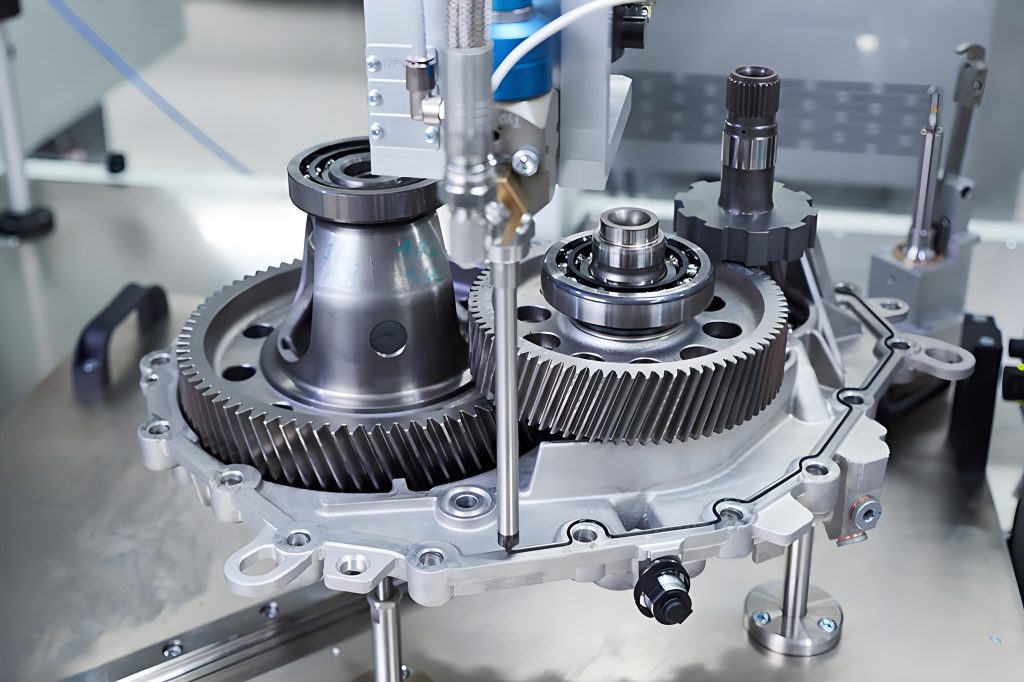

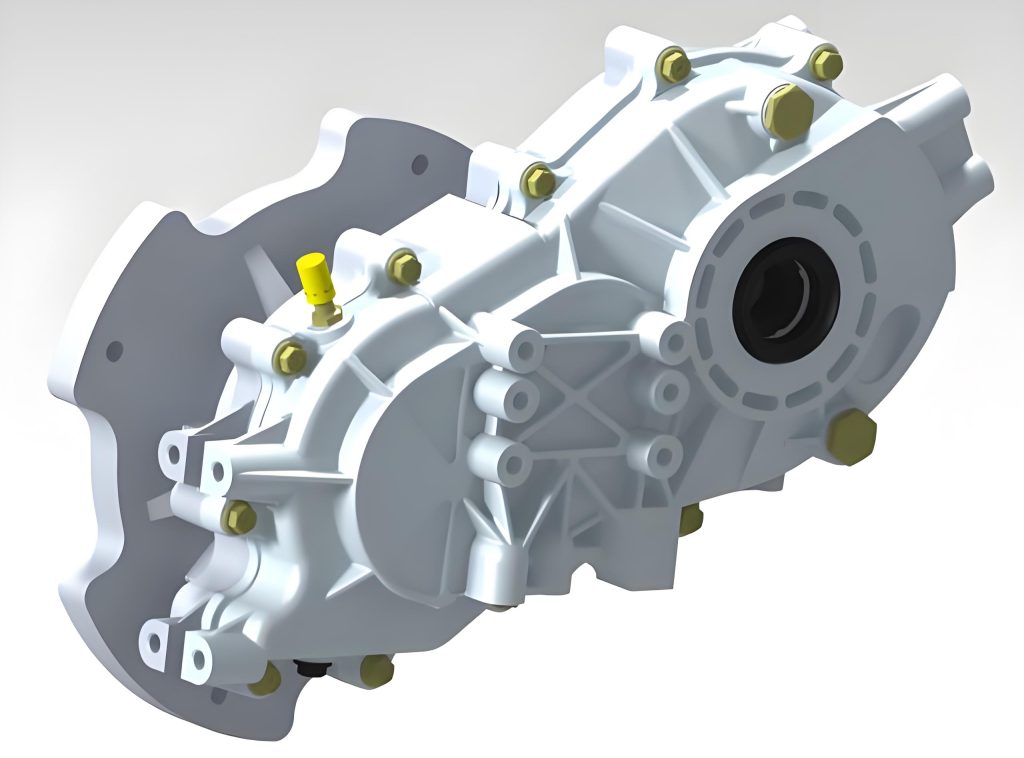

Customization and machining of gearbox gears

Electric vehicles have higher requirements for the gears of their transmissions. Compared to the transmissions of gasoline vehicles, planetary transmissions are smaller and lighter, and correspondingly, they also have higher requirements for gear processing.

HOFeng relies on a complete CNC industrial manufacturing system to handle the processing of various gears.

The advantages of customized gears for electric vehicle transmissions

- Can reduce the noise of the motor;

- The clutch can provide torque damping;

- It can expand the high efficiency range of the motor;

- Make the whole vehicle more powerful;

- It can reduce the requirements of the motor

Design and development capability

OUR SERVICE

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development