Fastest quote by uploading 3D data

Metal Cutting and Forming

- Accommodate complex bending and laser processing of special shapes

- Accommodate various materials and surface treatments Fastest delivery in 1 day, even for 1 piece

The files you upload are strictly confidential and secure

Metal Cutting and Forming Service

Work with various processing methods and special shapes such as laser cutting, CNC punching and nesting, bending, and spraying.

Work with various processing methods and special shapes such as laser cutting, CNC punching and nesting, bending, and spraying.

Work with various materials such as stainless steel, carbon steel, and aluminum alloys.

Capable of automatically identifying hole types.

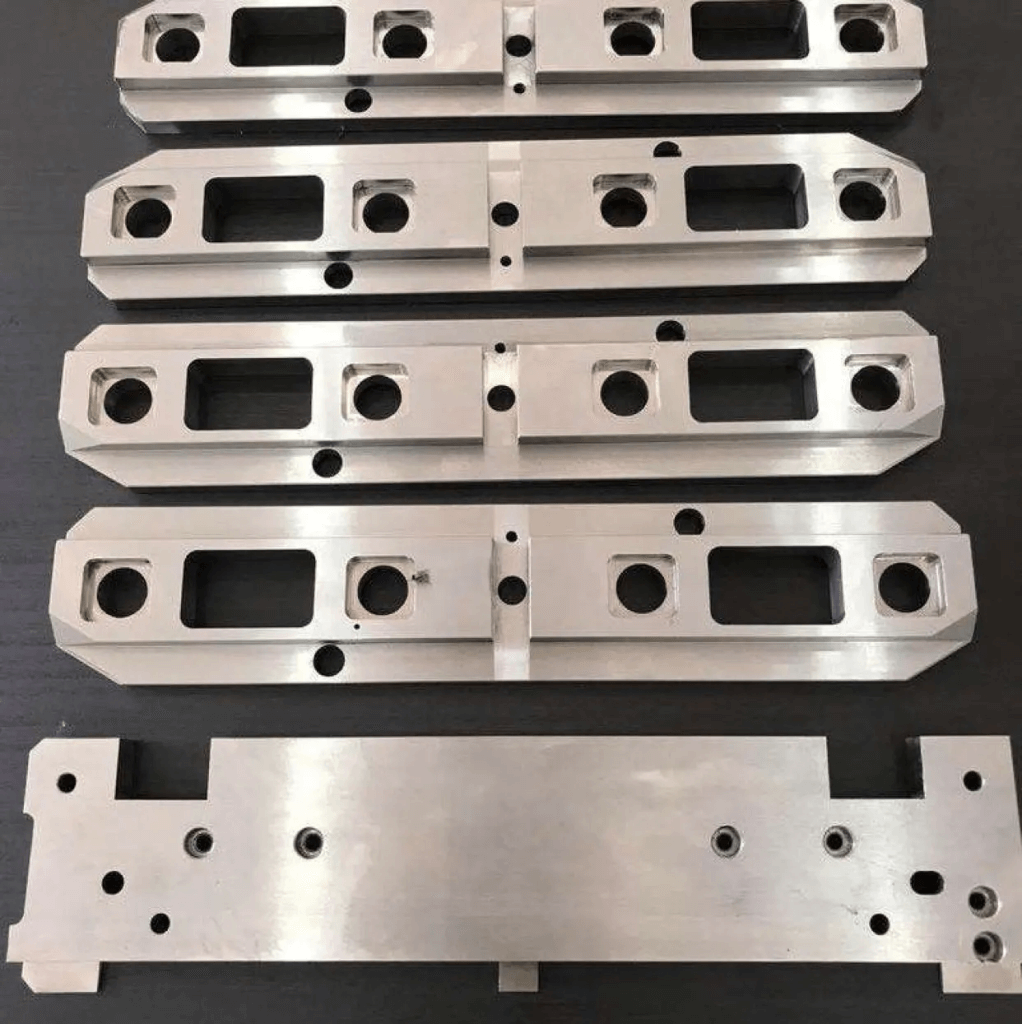

Sheet Metal Fabrication Capabilities

HOFeng's equipped with robot CO2 welding, robot polishing, robot laser welding, laser platform welding, laser cutting machine, handheld laser welding, CNC punch machine, bending machine, automatic deburring machine to improve the speed and ability to cope with mass production applications.

large sheet metal fabricators

Sheet metal processing of sheet metal chassis and cabinet

Decades of Sheet Metal Fabrication Expertise

If you’re looking for a sheet metal fabricator that can handle everything from new product development and prototype parts to large production runs and assembly services, HOFeng is a cut above what you’ve come to expect.our experts manage every step of the process, from design assistance and metal fabrication to painting, screen printing, kitting and assembly.

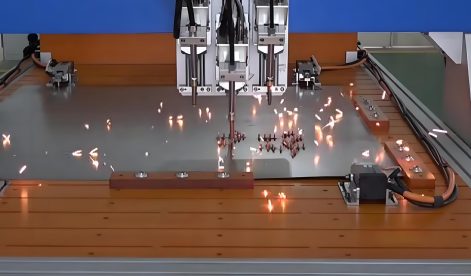

CNC Punching

Our CNC punch presses can accurately process standard features and complex shapes into sheet metal to meet your requirements. The turret punch that we employ can punch to a thickness of up to 1/4 inch and We can also produce special features such as countersinks, beads and louvers.

sheet metal bending

ISO9001

Lead time as fast as one day

Aluminium, Steel, Stainless Steel and more

The sheet metal bending machine is mainly used to bend the sheet in a straight line. The press bending process is mainly used for the processing of parts with large production batches, complex shapes and high precision requirements.

Deliver accurate angles with our bending services, achieving a final product that fits within tight tolerances.

laser cutting service sheet metal fabrication

Laser cutting uses a powerful laser that is intensified through lenses or mirrors. It is a precise and energy-efficient machine suitable for thin or medium gauge sheet metal, but may have difficulty penetrating the hardest materials.

Water Jet Cutting

Water jet cutting is a sheet metal manufacturing method that uses a high-pressure water jet (mixed with an abrasive substance) to cut metal. HOFeng’s water jet cutting service is a versatile and cost-effective solution for precision metal parts cut with a high degree of accuracy.Our large-format water jet machines can cut materials up to 6 inches thick with a tolerance of 0.005″- 0.015″.

CNC Plasma Cutting

Plasma cutting is more effective for cutting non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel); its main advantage is that when cutting metals with small thickness, plasma cutting speed is fast, especially cutting ordinary carbon steel thin plates.HOFeng plasma cutting service can provide high-precision complex parts on materials such as aluminum, steel and stainless steel.

Sinker and Wire EDM

Sinker EDM involves using electrical discharges to erode the workpiece surface to create desired shapes. On the other hand, Wire EDM utilizes a thin wire to cut the workpiece, suitable for high-precision and complex shape machining. Help high-precision requirements in workpiece manufacturing and improve production efficiency.

Variety of Welding Methods

HOFeng boasts four primary welding techniques: TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), MAG (Metal Active Gas), and CO2 welding. Each of these methods offers unique advantages and is suitable for different welding applications, ranging from precision welding to heavy-duty fabrication.

Surface Finishing & Assembly

"Surface Finishing" refers to the processes used to improve the appearance, surface durability, and corrosion resistance of a product. These finishing options include powder coating, anodizing, plating, polishing, Brushing and more. Surface finishing is essential for enhancing the overall quality and aesthetics of the final product, as well as protecting it from environmental factors such as rust and corrosion.

"Secondary Processes" refer to additional operations or services that may be required after the initial manufacturing process is completed. These secondary processes can include activities such as CNC bending, grinding, tapping, knurling, and more. These services are essential for achieving the desired final product specifications and quality standards.

Metal Fabrication Materials

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

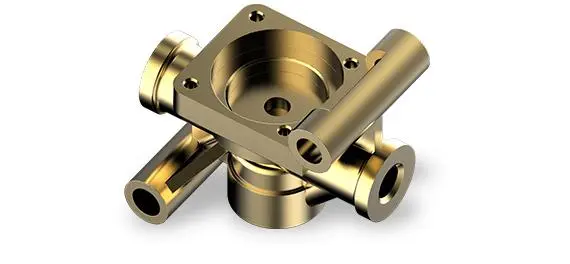

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development

Why choose HoFeng

Precision and Accuracy

1. Our precision machines and state-of-the-art software ensure accuracy and consistency in every product we create.

2. Strict quality control processes guarantee that every product meets our high standards and is exactly to specification.

Quick Response

1. Experienced engineering and operations team

2. In-house machine shop,24/7hours operations

3. Quick turnaround,High quality is our top priority

4. Help you with instant quotations, production, and delivery

Quality Assurance

1. Our ISO 9001-certified quality management system ensures reliable

2. All parts are dimensionally checked with calibrated equipment so that they meet your exact specifications.

3.250+Projects Delivered Per Month,10000+SQ METER AREA, 15+ YEARS OF SERVICE