Water Jet Cutting service

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part

- No minimum order quantity

- Rapidly-made in a Few Days

- Rapid Prototyping and Full Production Runs

- Over 30+ Metal and Plastic Materials Available

- Our ISO 9001 Certified Deliver Grade Quality With Every Batch

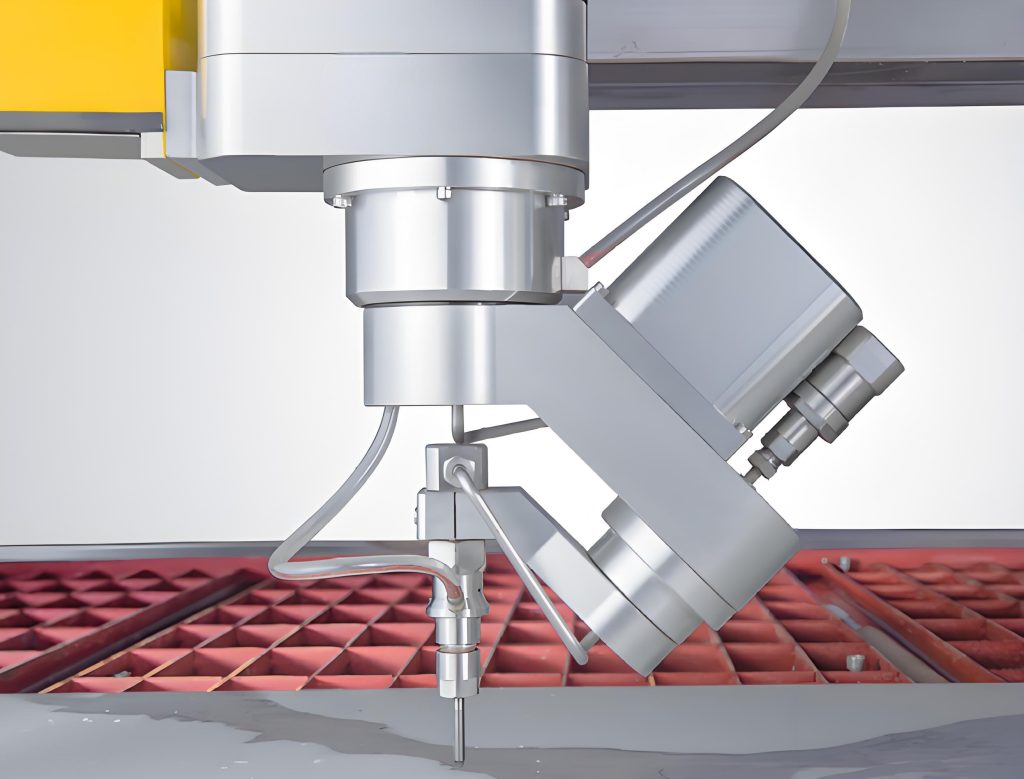

what is water jet cutting

Leading Waterjet Cutting Manufacturers

Water jet is a high-pressure or ultra-high-pressure pump that pressurizes ordinary water medium, and then sprays it through a nozzle (orifice) at subsonic or supersonic speed to form a high-speed, high-energy, high-penetration water beam. It is mainly composed of four parts: high-pressure generation system, nozzle assembly, control valve group and high-pressure pipe fittings.Unlike laser cutting, waterjet cutting does not use heat, but is rather a cold-cutting process

Industries where water cutting jet technology has been successfully applied include machinery manufacturing, automobiles, aerospace, military industry, electronic power, petrochemicals, light industry, shipping, food, medical care, environmental protection, construction materials, municipal engineering, etc.

Abrasive Water Jet Cutting Characteristics

① It can cut any material – from cardboard to steel plate, granite, ceramics, concrete, etc.

② Cold cutting tool. When cutting with abrasive water jet, the workpiece temperature is within 80℃, and there is absolutely no thermal stress or thermal deformation. It is particularly suitable for cutting heat-sensitive materials, special alloy materials and composite materials.

③ Green, environmentally friendly and safe. Abrasive water jet cutting does not produce dust and toxic gases, no secondary pollution, and can provide a safe and clean working environment.

④ Highly automated and flexible. With the help of CNC system, any complex shape of special-shaped cutting can be performed, and the cut is smooth, the processing accuracy is high, and no secondary processing is required. Customers can conveniently draw, input or scan the required workpiece directly on the computer, select the workpiece material type, thickness, required cutting quality, and set the corresponding processing parameters, and then start processing to form the final product.

⑤Abrasive water jet cutting has low investment cost, high production efficiency, and good economic benefits.

Water Jet Special Processing Has The Following Advantages.

●It can be used with a wide variety of material types,ect:

Special alloys: such as titanium alloy, nickel-iron alloy, nickel-based alloy, Non-ferrous metals such as copper, brass, aluminum,Steel

●The cutting surface is smooth and Minimal secondary finishing required

●Incredible accuracy with Cost-effective

●Almost no heat is generated during abrasive water jet processing, which is cold processing.

●Quick change time, after processing one part, it only takes about 2 minutes to start processing another part of different materials and shapes.

Our Other Manufacturing Capabilities

We specialize in 3D printing, CNC machining, vacuum casting, injection molding and sheet metal fabrication, offering a wide variety of materials and surface finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development

ut your parts into production today

Upload your 3D file to get one step closer to the get instant quote dditive manufacturing of your pieces,