RAPID PROTOTYPING SERVICE,CUSTOM MANUFACTURED HIGH-VALUE PARTS.

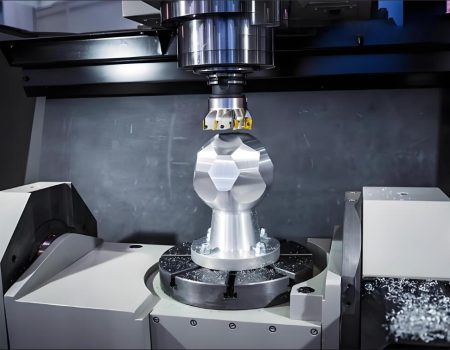

cNC machining services

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine,

drilling and post-processing using more than 50 different metals and plastics.

- Quick Quotes

- Parts in as Little as 14-Days or Less

- Available in more than 15 surface finishes.

- Tolerances down to ±.0000394" (0.001mm )

what is cnc machining services

Numerical control machining refers to a process of machining parts on a numerically controlled machine tool. It is a mechanical machining method that uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of variable parts, small batch size, complex shape and high precision, and to achieve high efficiency and automatic processing.

CNC Drilling

CNC Cutting

CNC Grinding

Wire EDM Machining

Custom Sourced Materials

We will recommend the most suitable and economical materials to produce your parts. If you need customized materials, we will submit a quotation to our engineers based on your needs.

Titanium alloy frame

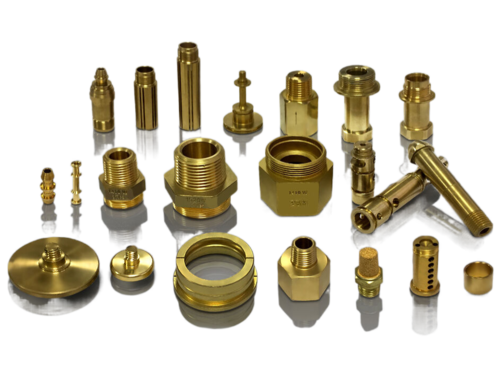

Precision copper connector

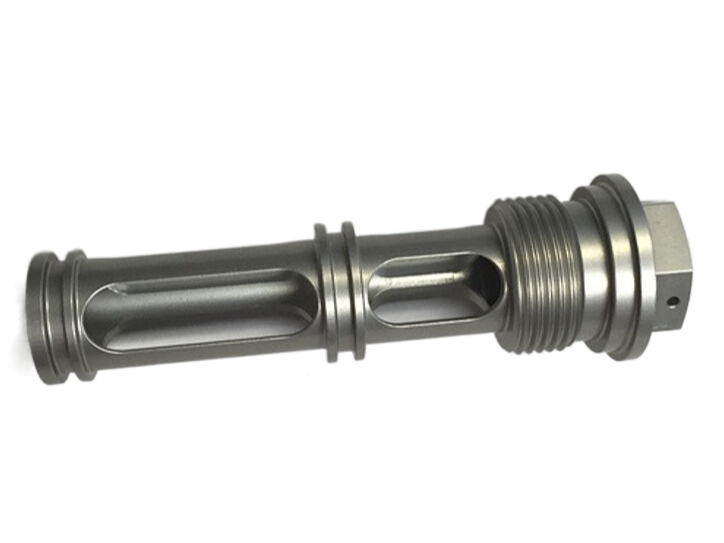

Milling machine spare parts

Drone spare parts

CNC aviation parts

Drone spare parts

Post-Processing & Finishing Options

Surface treatment in CNC machining refers to the process of applying a specific finish or coating to the surface of a machined part. This can include methods such as painting, anodizing, plating, or polishing to improve the appearance, corrosion resistance, or durability of the part.

Finishes for Metal //

| Standard Machined Finish |

| Tumbled |

| Bead Blasted (Sand or Glass) |

| Polished |

| Anodized |

| Chemical Film |

| Passivation |

| Powder Coating |

| Electro Polishing |

| Electroless Nickel Plating |

| Silver Plating |

| Gold Plating |

| Painting |

Finishes for Plastic //

| Standard Machined Finish |

| Flame or Vapor Polished (Acrylic Only) |

| Powder Coating |

| Tumbled |

| Painting |

Our manufacturing capabilities

HOFeng invests a lot in advanced CNC machining technology and CNC machining equipment to increase the speed and capability of mass-production applications. We offers different general tolerance options from 0.10mm to 0.05mm,Our ISO 9001 ISO,13485 and ITAR. certified production process, combined with professional experiences and advanced CNC machines ensures your parts are made right the first time, every time.

• Tight tolerance ±0.05mm

• Surface roughness Ra0.2μm

• ISO 9001:2015 certified

• 100% part inspection

Available Material

Tolerance FINISH & APPEARANCE Application

| Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380, etc | +/- 0.01~+/-0.005mm | Oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc. | |

| Brass | HPb63, HPb62, HPb61, HPb59, H59,H68, H80, H90, etc | +/- 0.01~+/-0.005mm | Electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment,pickling, shot peening,etc. | |

| Copper | C11000, C12000, C22000, C26000, C28000, C36000 | +/- 0.01~+/-0.005mm | Electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment,pickling, shot peening,etc. | |

| Stainless Steel | 303, 304, 304L, 316, 316L, 410, 420, 430, etc | +/- 0.01~+/-0.005mm | Electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot peening,etc. | |

| Low Carbon Steel | Mild Steel 1018,Mild Steel 1045,Mild Steel A36,Steel C45,Steel S355J2,Steel S235JR | +/- 0.01~+/-0.005mm | Standard Machined Finish, Tumbled,Bead Blasted (Sand or Glass), Painted, Powder coat,Post Processing Finishes | |

| Steel | Mild Steel, Carbon Steel, 1018, 1035, 1045, 4140, 4340, 8620, XC38, XC48, E52100, Q235, SKD11, 35MF6Pb, 1214, 1215, etc | +/- 0.01~+/-0.005mm | Electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot peening,etc. | |

| Titanium Alloy | TC1, TC2, TC3,TC4, etc | +/- 0.01~+/-0.005mm | Electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot peening,etc. | |

| Iron | A36,45#, 1213, etc | +/- 0.01~+/-0.005mm | • Standard Machined Finish • Tumbled • Flame or Vapor Polished (Acrylic Only) | |

| Plastic | ABS, PC, PP, PE, POM, Delrin, Nylon, Teflon, PEEK, PEI, etc | +/- 0.01~+/-0.005mm | Spraying,sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing, engraving, etc. | |

| HDPE | HDPE Matte Sheet ,HDPE Smooth Sheet,HDPE Pipe Grade,HDPE Antiskid, HDPE ColorCore | +/- 0.0008mm | Standard Machined Finish• Tumbled• Flame or Vapor Polished | |

| PC | +/- 0.008” | Standard Machined Finish • Tumbled • Flame or Vapor Polished (Acrylic Only | Polycarbonate (PC) // Transparent thermoplastic polymer. Strong, recyclable, heat and weather resistant. Can be used to make parts that touch food. High impact resistance makes it an excellent glass replacement.Good heat resistance and can be easily shaped without cracking. Applications include safety helmets, faceshields, insulators, lenses, packaging, aerospace parts, and automotive parts. | |

| ABS | Acrylonitrile Butadiene Styrene (ABS) // Strong and tough. Offers good chemical and thermal stability along with high heat deflection and dimensional stability. ABS has excellent electrical insulation and is suitable for many different environments. Used for pipes, keyboards, and refrigeration parts.

| |||

| Nylon 6/6 | Standard Machined Finish • Tumbled • Flame or Vapor Polished (Acrylic Only) | Nylon 6/6 // Also known as nylon 6-6, nylon 6,6, polyamide 66 or PA 66. Milky white, grey, or black in appearance. Excellent strength and stiffness, lower moisture absorption. Offers chemical, heat, corrosion,and abrasion resistance. Used for medical components, electronics, aerospace, gears, electronic casings,wheels, and other structural components.

| ||

| ULTEM® | +/- 0.008” | Standard Machined Finish • Tumbled • Flame or Vapor Polished (Acrylic Only) | Ultem® is a thermoplastic used to make seals, valves, medical instruments, missile components, electrical hardware, aircraft components and more. Ultem® CNC is perfect for applications that require thermal... (continued on next page)

| |

| Acrylic | +/- 0.0008mm | Standard Machined Finish• Tumbled• Flame or Vapor Polished(Acrylic Only) |

Why choose HoFeng

Precision and Accuracy

1. Our precision machines and state-of-the-art software ensure accuracy and consistency in every product we create.

2. Strict quality control processes guarantee that every product meets our high standards and is exactly to specification.

Quick Response

1. Experienced engineering and operations team

2. In-house machine shop,24/7hours operations

3. Quick turnaround,High quality is our top priority

4. Help you with instant quotations, production, and delivery

Quality Assurance

1. Our ISO 9001-certified quality management system ensures reliable

2. All parts are dimensionally checked with calibrated equipment so that they meet your exact specifications.

3.250+Projects Delivered Per Month,10000+SQ METER AREA, 20+ YEARS OF SERVICE

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development

CNC Machining FAQs

How quickly can I get my parts?

Quality parts less than 800pcs can be made in as fast as one week if you provide complete 2D and 3D CAD models. More complex parts requiring other special features will take longer.

What considerations should be made when designing parts for CNC machining?

Designers should consider factors such as tool access, material selection, tolerances, and surface finishes when designing parts for CNC machining.

How long does a CNC machining process typically take?

The duration of a CNC machining process depends on factors such as the complexity of the part, the material being used, and the desired tolerances. It can range from minutes to hours.

What certifications or industry standards do you adhere to in your CNC machining processes?

HOFeng is ISO 9001 certified, ISO 13485 compliant.

What tolerances can your CNC machines achieve?

Our machines are capable of tolerances as tight as +/- 0.0002 inches.