CNC turning service

HOFeng offers CNC machining, sheet metal fabrication, injection molding, 3D printing,punching, laser cutting, stamping, bending, and welding sheet metal services

- Fast Response, Quote in Hours

- 50+ Materials.

- 100% Quality Guaranteed

- Tight tolerances available, down to ±.0008″

All uploads are secure and confidential.

What is CNC Turning?

CNC turning is a subtractive manufacturing process technology that excels in cutting material to create round shapes with utmost precision. Utilizing state-of-the-art CNC lathes, we produce accurate round shapes, often with precise outer diameters (OD) and inner diameters (ID).CNC turned prototypes and production parts in days AS9100D,ISO 9001:2015,IATF 16949:2016

The process begins with placing the workpiece inside the lathe, which rotates while a cutter removes material until only the desired shape remains. This approach contrasts with CNC milling, where the workpiece remains stationary, and the cutting tool moves. In CNC turning, the workpiece rotates, and a stationary tool is introduced into the workpiece to achieve the desired shape.

Our advanced CNC turning centers further enhance this process by integrating milling functionality, enabling the production of highly complex parts. This versatility allows us to meet the diverse needs of our clients, whether they require rapid prototyping or low-to-high volume production runs.

Our manufacturing platform is equipped to deliver high-quality metal and plastic CNC turning parts, ensuring that every component meets the strict quality standards set by our clients. We pride ourselves on our ability to provide precise, reliable, and cost-effective CNC turning solutions that cater to a wide range of industries and applications.

Custom CNC Turning Services

Vertical milling machine

CNC Grinding

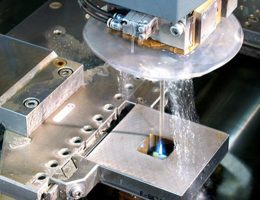

Wire EDM Machining

CNC Turning Workshop

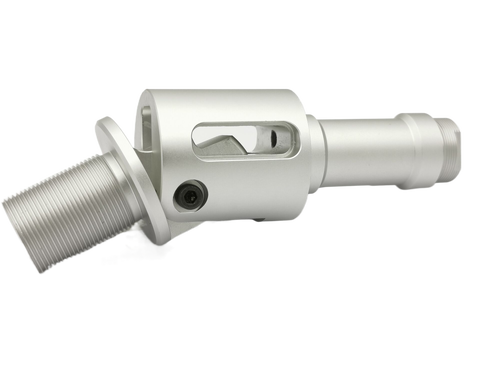

HOFeng Turned Parts

CNC Turning Services

CNC metal turning services offer an efficient and precise way to transform solid chunks of raw metal into custom finished products that meet the exact specifications of your project. At our facility, we provide advanced metal CNC turning services that are tailored to the unique requirements of each project.

Our highly skilled technicians utilize a wide range of CNC turning services to produce custom parts or components that are tailored to your specific needs. Whether you require precision machining for intricate designs or large-scale production runs, we have the capabilities to deliver exceptional results.

Our CNC turning machines are equipped with premium-quality materials such as carbon steel, alloy steel, and stainless steel, ensuring the durability and reliability of the finished product. We carefully select the appropriate CNC machine tools for each material to ensure optimal machining performance.

Prior to starting the CNC turning production process, we take into account the density of the material and the rotation of the cutting tool to ensure precision and accuracy. This ensures that the finished product closely matches the desired design specifications.

Our CNC turning production capabilities include a range of operations such as facing, parting, grooving, boring, drilling, and knurling. Our machinists are skilled in operating CNC turning lathes, ensuring that the dimensions of the finished product exactly fit the blueprint specifications.

Custom Sourced Materials

We will recommend the most suitable and economical materials to produce your parts. If you need customized materials, we will submit a quotation to our engineers based on your needs.

Facing

Turning

Drilling

Boring

Post-Processing & Finishing Options

Surface treatment in CNC machining refers to the process of applying a specific finish or coating to the surface of a machined part. This can include methods such as painting, anodizing, plating, or polishing to improve the appearance, corrosion resistance, or durability of the part.

Finishes for Metal //

| Standard Machined Finish |

| Tumbled |

| Bead Blasted (Sand or Glass) |

| Polished |

| Anodized |

| Chemical Film |

| Passivation |

| Powder Coating |

| Electro Polishing |

| Electroless Nickel Plating |

| Silver Plating |

| Gold Plating |

| Painting |

Finishes for Plastic //

| Standard Machined Finish |

| Flame or Vapor Polished (Acrylic Only) |

| Powder Coating |

| Tumbled |

| Painting |

Why choose HoFeng

Precision and Accuracy

1. Our precision machines and state-of-the-art software ensure accuracy and consistency in every product we create.

2. Strict quality control processes guarantee that every product meets our high standards and is exactly to specification.

Quick Response

1. Experienced engineering and operations team

2. In-house machine shop,24/7hours operations

3. Quick turnaround,High quality is our top priority

4. Help you with instant quotations, production, and delivery

Quality Assurance

1. Our ISO 9001-certified quality management system ensures reliable

2. All parts are dimensionally checked with calibrated equipment so that they meet your exact specifications.

3.250+Projects Delivered Per Month,10000+SQ METER AREA, 20+ YEARS OF SERVICE

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development

CNC Machining FAQs

If you have a CNC machining project ready to commence, we are here to assist you from start to finish. With our extensive range of optional post-processing services and rigorous quality assurance measures implemented by our dedicated QC department, you can rest assured that you will receive products that meet your expectations.

Simply send us your 3D CAD files, and our team will provide you with a free quote. Our experienced model engineers will perform a thorough design for manufacturability (DFM) analysis on your design, ensuring that the final product not only meets your quality standards but also fits within your budget constraints.

How quickly can I get my parts?

Quality parts less than 800pcs can be made in as fast as one week if you provide complete 2D and 3D CAD models. More complex parts requiring other special features will take longer.

What considerations should be made when designing parts for CNC machining?

Designers should consider factors such as tool access, material selection, tolerances, and surface finishes when designing parts for CNC machining.

How long does a CNC machining process typically take?

The duration of a CNC machining process depends on factors such as the complexity of the part, the material being used, and the desired tolerances. It can range from minutes to hours.

What certifications or industry standards do you adhere to in your CNC machining processes?

HOFeng is ISO 9001 certified, ISO 13485 compliant.

What tolerances can your CNC machines achieve?

Our machines are capable of tolerances as tight as +/- 0.0002 inches.