خدمات تصنيع الصفائح المعدنية النموذجية

يمكن ل HOFeng مساعدتك في صنع العبوات والأقواس والتركيبات واللحامات والخزانات والمباني وغيرها من أجزاء الصفائح المعدنية والنماذج الأولية بسرعة ودقة

لا يوجد موك (الحد الأدنى لكمية الطلب)

الفحص 100% لكل جزء 100%

الملفات التي تقوم بتحميلها سرية وآمنة تماماً

تطبيقات تصنيع الصفائح المعدنية

لدينا أكثر من 60 ماكينة تحكم رقمي باستخدام الحاسب الآلي في مصنعنا

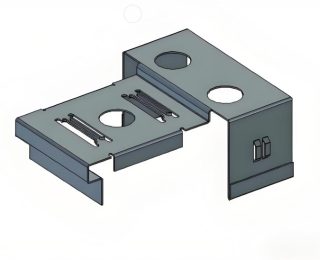

النماذج الأولية للصفائح المعدنية

النماذج الأولية للصفائح المعدنية

سواء كنت بحاجة إلى

قوس، هيكل، هيكل

أو أي ضميمة أخرى

صفائح معدنية معقدة

التصميم، يمكننا تلبية احتياجاتك

منتجات الصفائح المعدنية

منتجات الصفائح المعدنية

إنتاجنا بكميات منخفضة

يمكن أن تنتج المنشأة ما يصل إلى

60 إلى 1500 صفائح معدنية

الأجزاء في مدة تصل إلى 10 أيام.

تجميعات متعددة الأجزاء

وبفضل موظفينا ذوي الخبرة وبروتوكولات الجودة الصارمة التي نتبعها، يمكننا أن نضمن أن منتجات الصفائح المعدنية ستقدم منتجًا نهائيًا مطابقًا من المرة الأولى.

مواد النماذج الأولية للصفائح المعدنية - تصنيع الصفائح المعدنية في الصين

بصفتنا شركة رائدة في تصنيع الصفائح المعدنية في الصين، تتمتع HOFeng بخبرة 15 عامًا في تصنيع الصفائح المعدنية، مما يساعدك على توفير منتجات معدنية عالية الجودة والدقة بأسعار تنافسية، وتقدم HOFeng مجموعة متنوعة من مواد تصنيع الصفائح المعدنية، بما في ذلك الفولاذ المقاوم للصدأ والألومنيوم والنحاس والنحاس الأصفر والنحاس الأصفر والصلب المجلفن، ويمكننا مساعدة العملاء على اختيار المواد المناسبة لمشاريع النماذج الأولية الخاصة بهم.

ما هي النماذج الأولية للصفائح المعدنية

معالجة الصفائح المعدنية هي طريقة للتشكيل على البارد والساخن، والتجميع، وتوصيل الألواح المعدنية، والمقاطع الجانبية والأنابيب لتصنيع المكونات المعدنية عن طريق اللحام والتثبيت والتثبيت بالبراغي. وهي تتضمن بشكل أساسي أعمال المناضد، والختم، وقطع المعادن، واللحام، والمعالجة الحرارية، والمعالجة السطحية، والتثبيت، والتجميع وأنواع أخرى من الأعمال الاحترافية.

إمكانيات النماذج الأولية الشاملة لدى HOFeng

يغطي مصنعنا مساحة 6000 + متر مربع، مع مرافق كاملة للأجهزة والبرامج، بما في ذلك أكثر من 60 ماكينة تثقيب، و30 مركزًا للتثقيب باستخدام الحاسب الآلي، و3 ماكينات قطع بالليزر، والعديد من ماكينات الثني باستخدام الحاسب الآلي، ولدينا آلات تشمل القطع والثني واللكم والحفر واللحام والتشكيل. كما أن الشركة مجهزة بالعديد من مصممي تطوير القوالب الدقيقة ومصممي البرمجة باستخدام الحاسب الآلي ذوي الخبرة، وجميع المنتجات تتوافق مع معايير توجيه ROHS، ويمكن لماكيناتنا إزالة النتوءات والحواف الحادة بكفاءة، والطحن الدقيق، والصنفرة بالحزام العريض، مما يعزز سلامة وجمالية مكونات الصفائح المعدنية الخاصة بك، مما يضمن أن منتجاتك من الصفائح المعدنية تلبي أعلى المعايير.

وبالإضافة إلى ذلك، نقدم مجموعة متنوعة من التشطيبات، بما في ذلك الطلاء بالمسحوق، والطلاء بأكسيد الألومنيوم. كما نوفر أيضاً القطع بالليزر المخصص,

خدمات القطع بالنفث المائي، والتقطيع بالنفث المائي، والتقطيع السلكي EDM، والحفر الكيميائي للصور، والتثقيب، وخدمات التشكيل. يكرِّس فريقنا من المهندسين والفنيين المهرة جهودهم لتزويد عملائنا بأعلى جودة للقطع وخدمة عملاء ممتازة. سواءً كنت بحاجة إلى بعض النماذج الأولية أو إلى حجم إنتاج منخفض، فنحن نوفر لك جميع احتياجاتك من تصنيع الصفائح المعدنية. اتصل بنا اليوم للحصول على عرض أسعار مجاني!

عملية تشطيب الصفائح المعدنية

1- تشطيب قياسي

الطحن والتلميع

التنظيف بالفرشاة

2. السفع بالخرز

3. الطلاء بأكسيد الألومنيوم

أنودة (النوع الثاني أو النوع الثالث)

الكرومات

الزنك

التخميل

نيكل عديم النيكل

صفيح

تشير الفئة 1 إلى غير المصبوغة وتشير الفئة 2 إلى المصبوغة

الطلاءات. على الرغم من أن الأسود هو النوع 2 الأكثر شيوعًا

أنودة, هناك الشفاف والأزرق والأحمر والذهبي والذهبي والأصفر,

برتقالي، أخضر، بنفسجي

والأصباغ الأخرى المتاحة.

تشير الفئة 1 إلى طلاء صلب شفاف بينما تشير الفئة 2 إلى

معطف صلب أسود.

4. طلاء الغشاء الكيميائي

5- طلاء المسحوق

6. الطلاءيمكن أن توفر خيارات الطلاء (أو الطلاء) مقاومة للتآكل، وتحسن خصائص التآكل، وتساعد في التوصيل مع تحسين المظهر مع تحسين المظهر بجودة عالية ولمسة نهائية موحدة.

تشمل خيارات الطلاء المتاحة ما يلي:

أنودة (النوع الثاني أو النوع الثالث)

الكرومات

الزنك

التخميل

نيكل عديم النيكل

صفيح

7. الفحص الحريري

تُستخدم هذه العملية غالباً لإضافة الملصقات أو التعليمات أو الأنماط الزخرفية على المنتجات المعدنية المصنعة.

8. التقشير بالخردق 9 التجميع والتركيب

قدراتنا التصنيعية الأخرى

نحن متخصصون في الطباعة ثلاثية الأبعاد، والتصنيع باستخدام الحاسب الآلي، والصب بالتفريغ، والقولبة بالحقن، وتصنيع الصفائح المعدنية، ونقدم مجموعة متنوعة من المواد والتشطيبات السطحية.

التصنيع الآلي باستخدام الحاسب الآلي

لدينا مركز تصنيع آلي مركب بالدوران في ماكينة تفريز مركّب، وماكينة تفريز ذات 3 محاور قياسية ذات 3 محاور و5 محاور مستمرة، وماكينة تفريز ذات 3+2 محور، وماكينة حفر ومعالجة لاحقة باستخدام أكثر من 50 معدنًا وبلاستيكًا مختلفًا، متوفرة بأكثر من 15 تشطيبًا سطحيًا. تفاوتات تصل إلى ±.0000394 بوصة (0.001 مم)

خدمات القولبة بالحقن

يمكن لشركة HOFeng قولبة أي بلاستيك حراري. خدمات قولبة حقن فعالة من حيث التكلفة لمنتجاتك وأجزائك المخصصة. أداة نموذج أولي في غضون 10 أيام أداة إنتاج في غضون أسبوعين، ISO 9001:2015 | أداة إنتاج في غضون أسبوعين، ISO 9001:2015 | فحص الجودة

خدمة الطباعة ثلاثية الأبعاد

خدمة الطباعة ثلاثية الأبعاد من HOFeng هي مركز إنتاج التصنيع المضاف لأكثر من 30 مادة لأي تطبيق، خدمة الطباعة ثلاثية الأبعاد نحن خبراء طباعة ثلاثية الأبعاد لتلبية جميع متطلباتك من الدرجة الصناعية.

خدمات صب اليوريثان

صنع النماذج الأولية السريعة وإنتاج الأجزاء، أجزاء بسرعة 10 أيام، فحص 100% لكل جزء، لدينا شهادة ISO 9001 معتمدة من ISO 9001 تقدم جودة عالية مع كل دفعة، نحن خبراء مواد البولي يوريثين في تطوير منتجاتك

أنت تسأل، ونحن نجيب

خدمات تصنيع الصفائح المعدنية

يمكن للنماذج الأولية للصفائح المعدنية تسريع عملية تطوير مشروعك من خلال التكرارات السريعة والمرنة والموثوقة للتصميم واختبار الوظائف والانتقال من المفهوم إلى السوق بسرعة.