1. As IoT devices get smaller, smarter, and more connected, picking the right IoT enclosure manufacturer becomes key to your product’s performance, safety, and durability.

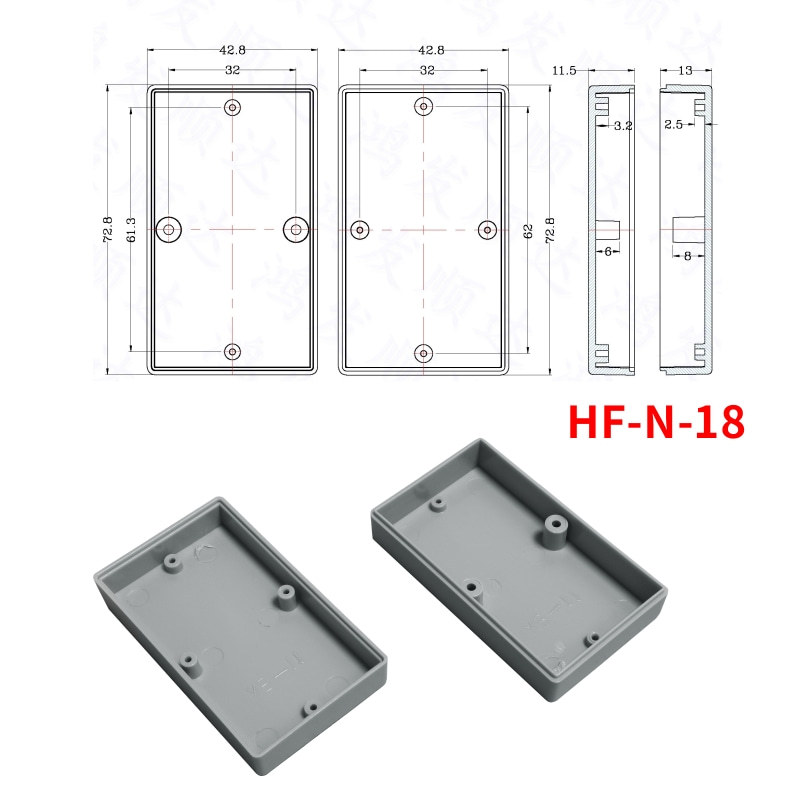

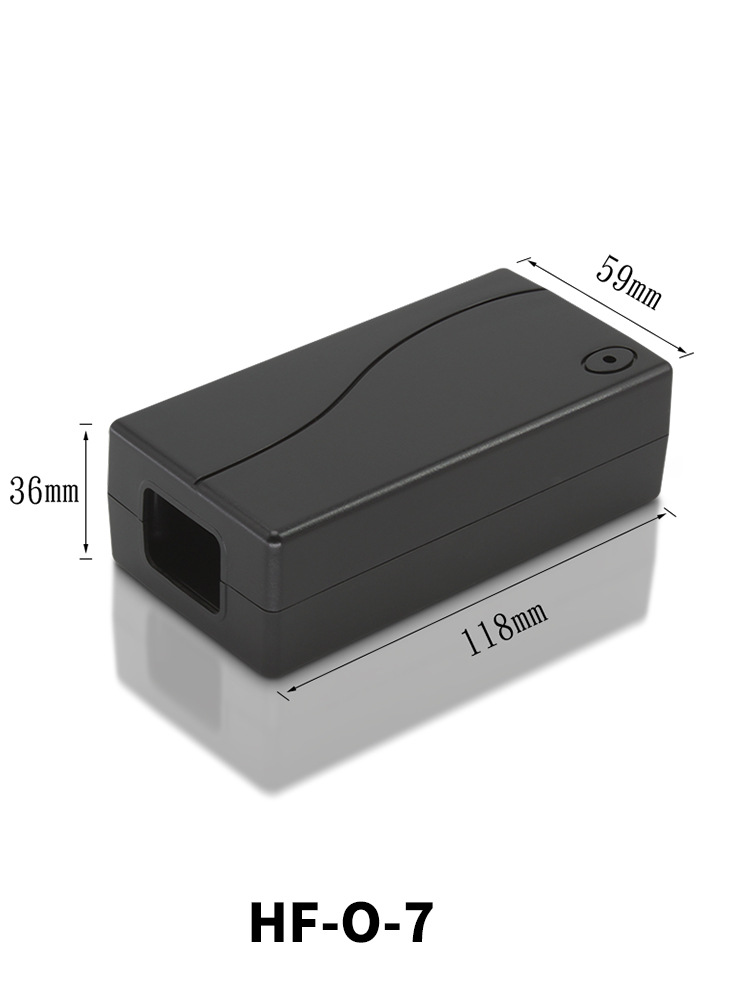

Whether you’re building a handheld plastic enclosure, a small PCB enclosure, or a rugged outdoor sensor housing, the enclosure plays a huge role in how well your electronics handle real-world environments.

2. Understanding IoT Enclosures

An IoT enclosure protects printed circuit boards (PCBs), batteries, sensors, and wireless modules from environmental challenges such as moisture, heat, vibration, and dust.

There are two main categories:

Indoor IoT device cases – lightweight and compact designs often used for gateways, smart home controllers, or handheld devices.

Outdoor IoT and sensor enclosures – durable housings built to resist UV exposure, water, and impact.

3. Material Options and Their Benefits

Choosing the right material for your enclosure depends on where and how your IoT device operates.

| Material | Features | Typical Use |

| ABS Plastic | Cost-effective, easy to machine, smooth finish | Handheld enclosures, small PCB housings |

| Polycarbonate (PC) | Strong impact resistance, transparent, UV-resistant | Sensor housings, outdoor IoT boxes |

| Aluminum Alloy | Excellent heat dissipation, EMI shielding | Industrial IoT controllers, power boxes |

| Stainless Steel | High strength, corrosion resistance | Harsh environment or marine applications |

4. IP Protection and Environmental Ratings

IoT devices operate in a variety of environments, so selecting the right protection rating is critical:

IP54: Provides limited protection against dust ingress and splashing water, suitable for indoor applications with minor exposure.

IP65 / IP67: Designed for outdoor sensor enclosures; ensures full dust-tightness and protection against water jets (IP65) or temporary immersion (IP67).

IP68: Guarantees long-term submersion resistance, making it suitable for underwater or buried deployments, where sustained water exposure is expected.

5. Customization Capabilities from Hofengfab

Professional IoT device case manufacturers provide one-stop customization services, including:

CNC machining, punching, and laser cutting for openings

Surface finishing: powder coating, sandblasting, anodizing

Logo printing and labeling

Custom battery compartments, PCB mounting holes, or cable glands

Rapid prototyping and small batch production

Customization not only improves the mechanical fit of your PCB and components but also enhances product identity and usability.

6. Applications of IoT and Sensor Enclosures

IoT and sensor enclosures are used across a wide range of industries, including:

Smart agriculture and environmental monitoring

Industrial automation and factory control

Smart home and energy management systems

GPS tracking and remote sensing

Audio and signal transmission devices

7. Hofengfab Capabilities

Hofengfab offers a full range of capabilities for IoT and sensor enclosures:

OEM/ODM project experience: Extensive track record in custom design and production.

In-house machining and molding: Complete control over precision manufacturing processes.

Material and surface finishing options: Wide selection to meet functional, aesthetic, and environmental requirements.

Customizable handheld and battery-powered enclosures: Designed for compact, portable IoT devices.

Certifications: ISO, CE, RoHS, and UL compliant, ensuring quality and regulatory compliance.

If you’re looking for a custom IoT enclosure manufacturer, our team provides full OEM/ODM service — from 3D design to production.

Contact us to discuss your next project. vivian@hofengfab.com