Solutions in the field of robot manufacturing

- A solution for mass production of robot components, including integrated processes such as component design and processing.

Robot component manufacturing services

Based on years of experience in CNC machining, HOFeng has a deep foundation in the design and processing of robot components, and can complete large quantities of component processing to ensure the strength and accuracy of the components.

Advantages of integrated design and manufacturing of robot parts

The integration of robot component design and manufacturing can ensure that the produced components are more in line with the precision of product design, which is more conducive to component manufacturing and assembly

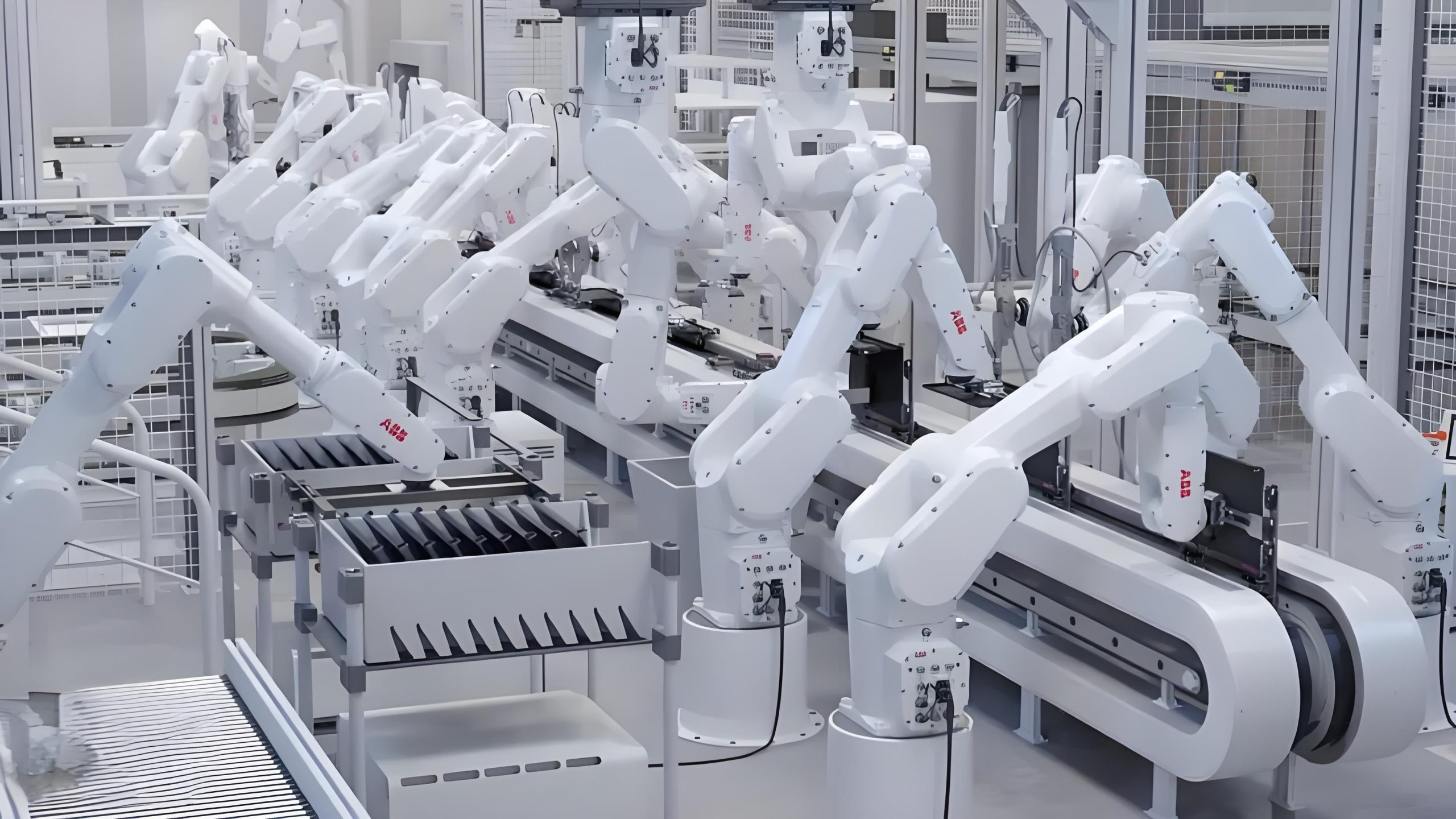

Mature industrial production process

HOFeng has experience in the field of CNC machining, with a complete set of industrial production processes, from product design to finished product production, and finally assembly. With mature industry project experience, it can meet the needs of customers for the production of customized components to the greatest extent possible.

The relationship between robots and CNC machine tools

With the help of CNC machine tools, interaction is achieved through programming instructions, sensor feedback, and other methods to control the motion, actions, and tasks of robots, achieving automated operations and production control. In the manufacturing industry, it can improve production efficiency, accuracy, and consistency, reduce human errors, lower production costs, and achieve advantages such as complex parts processing, making the production process more intelligent and improving production efficiency.

The development trend of robots in CNC machining

With the development of industrial intelligence, CNC technology and robots are both rapidly advancing. Just like UoAo robots, their application scenarios are becoming more and more extensive and complex. Correspondingly, CNC technology will become more and more complex and mature to adapt to more challenges and provide humans with more efficient, precise, and flexible production modes

Robot parts design and processing services

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development