Sheet Metal Fabrication for Medical Equipment Solutions

-

Sheet Metal Fabrication for Medical Equipment Solutions.

You can trust HOFeng for your sheet metal medical part needs.

We have profound experience and history, Our internal characteristic tolerance is maintained at ±0.001"

External characteristic tolerance is maintained at ±0.003", and metal materials as thin as 0.003" can be used.

Sheet Metal Fabrication for Medical Equipment Solutions

Medical devices themselves have the characteristics of "multiple varieties, small batches," and have special processing requirements for sheet metal structural components.

Sheet Metal Fabrication parts

The sheet metal parts in the main structure of medical devices are mainly divided into load-bearing components, connecting components, outer frames and auxiliary cabinets (such as power cabinets). In these structural components, apart from the connecting components which are mainly made of medium-thick plates, the rest are mostly thin plates. The materials are mainly stainless steel plates and aluminum plates, with some coated aluminum-zinc plates and cold-rolled steel plates.

The world's leading quality

Precision requirements for movable connecting components, especially the connecting components after welding, need to be coordinated and run consistently according to application software requirements.Surface appearance process requirements for outer frames, irregular appearance forming, surface without any defects, consistent welding and polishing.

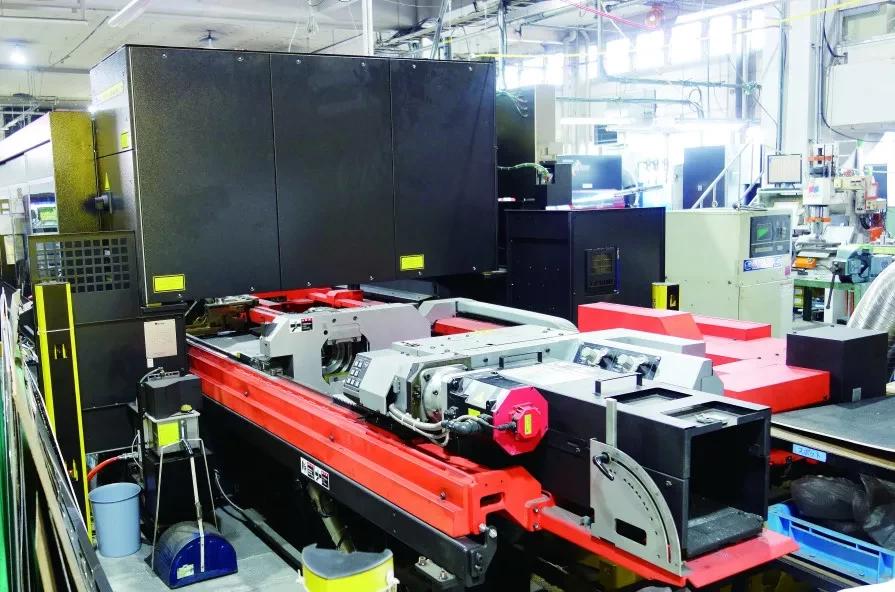

Sheet Metal Fabrication Factory in China

The Prototype Plant produces concept cars, test cars and prototypes for all stages of the design process, as well as highly customized, small-batch finished cars and components. Our advanced equipment technology and experienced employees enable us to create custom stamped metal parts and sheet metal manufacturing with strict tolerances and precise dimensions required for medical equipment. Our internal characteristic tolerance is maintained at ±0.001", external characteristic tolerance is maintained at ±0.003", and metal materials as thin as 0.003" can be used. We provide small to medium batch stamping parts and machined parts with excellent repeatability from the first part to the last part. Our professional team can produce an extensive variety of sheet metal parts for medical devices

Design and development capability

To ensure that all parts meet customer design requirements and our own high-quality standards, we have a complete mold workshop within our facility in Guangdong China, our internal tool manufacturing capability has improved production speed as we no longer need to wait for completed tools to be delivered to our location.

Manufacturing and testing capabilities

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development