Metal Stamping for the Electronics Industry

- Electronics Industry Sheet Metal Fabrication Service for Custom Parts

- Beat competition to market with rapid prototyping and on-demand production

- Multiple finishing options like anodizing and powder coating

Benefits of Metal Stamping for the Electronics Industry

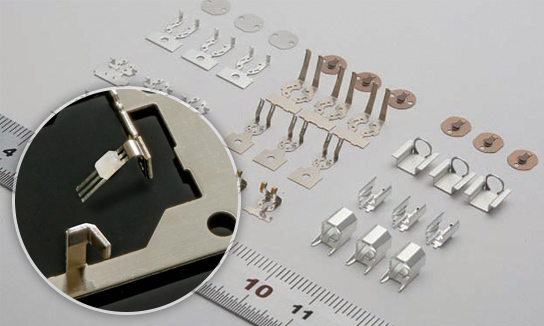

Sheet metal processing is a processing technology that applies force to thin metal plates to deform them. Through cutting, bending, stretching, stamping, extrusion and other processes, parts with certain shapes and sizes are produced. Sheet metal processing is widely used in the manufacturing industry. Equipment manufacturing, automobiles, communications electronics, home appliances, shipbuilding and other industries are inseparable from sheet metal processing.Metal stamping products are widely used in the consumer electronics industry, including smartphones, laptops, tablets, as well as new generation consumer electronic products such as smart wireless earphones, smart watches, smart speakers, VR devices, etc.

Our Metal Stamping Process

The process of metal stamping includes sheet cutting, forming, punching, bending, shaping, cleaning, and surface treatment. Forming is the core step in metal stamping processing, which requires making corresponding stamping dies according to the product design drawings, and forming metal sheets.

The equipment required for metal stamping processing includes punching machines, stamping dies, cutting machines, bending machines, shaping machines, cleaning machines, and surface treatment devices, etc. Metal stamping processing is widely used in industries such as automotive, electronics, and mechanical manufacturing, for example, automotive body parts, electronic casings, mechanical components, etc.

Secondary operations:

Pre-plating, post-plating, spot plating and other continuous electroplating and roll plating of copper-nickel-tin-gold

Customized packaging

Continuous roll-to-roll stamping and electroplating

Heat treatmen

Why HOFeng for Development of Consumer electronics industry

HOFeng precision products are mainly customized products, designed, tooled, stamped, and processed according to customer requirements. Due to their expertise in the production of precise and small-scale products, and their meticulous process management, the products have high accuracy and are highly compatible with the consumer electronics industry.

We have inherited our spirit for over 15 years, accumulating rich experience in stamping processing.

We have 23 stamping machines.

We have image measurement systems, automatic measurement systems.

Optical grinding machines, slow wire cutting, and more.

Our stamping parts meet the standards:

Mainly customized according to drawings, we provide customers with satisfactory products according to customer requirements, and the tolerance meets the requirements of the drawings. Comply with ROHS and REACH standards.

In the consumer electronics industry, the materials we use include:

Stainless steel alloy

High nickel alloy

Aluminum alloy

Malleable iron

PET

Material thickness ranges from 0.02 to 2.0 millimeters.

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development