RAPID PROTOTYPING SERVICE,CUSTOM MANUFACTURED HIGH-VALUE PARTS.

cNC machining services

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine,

drilling and post-processing using more than 50 different metals and plastics.

- Quick Quotes

- Parts in as Little as 14-Days or Less

- Available in more than 15 surface finishes.

- Tolerances down to ±.0000394" (0.001mm )

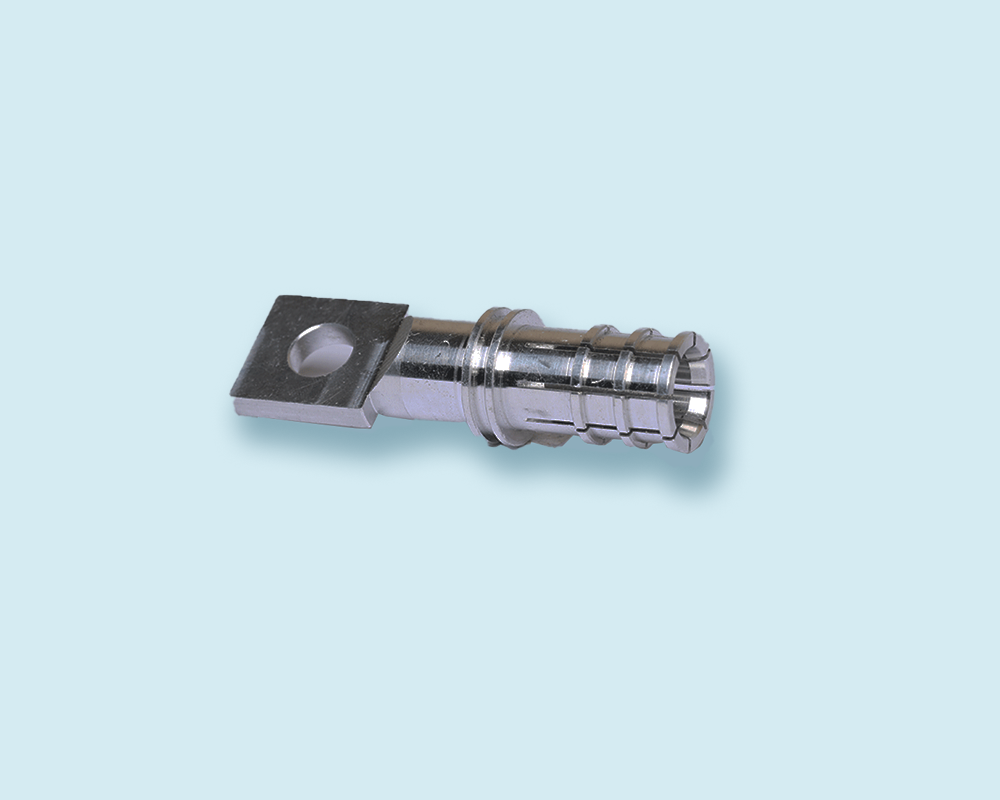

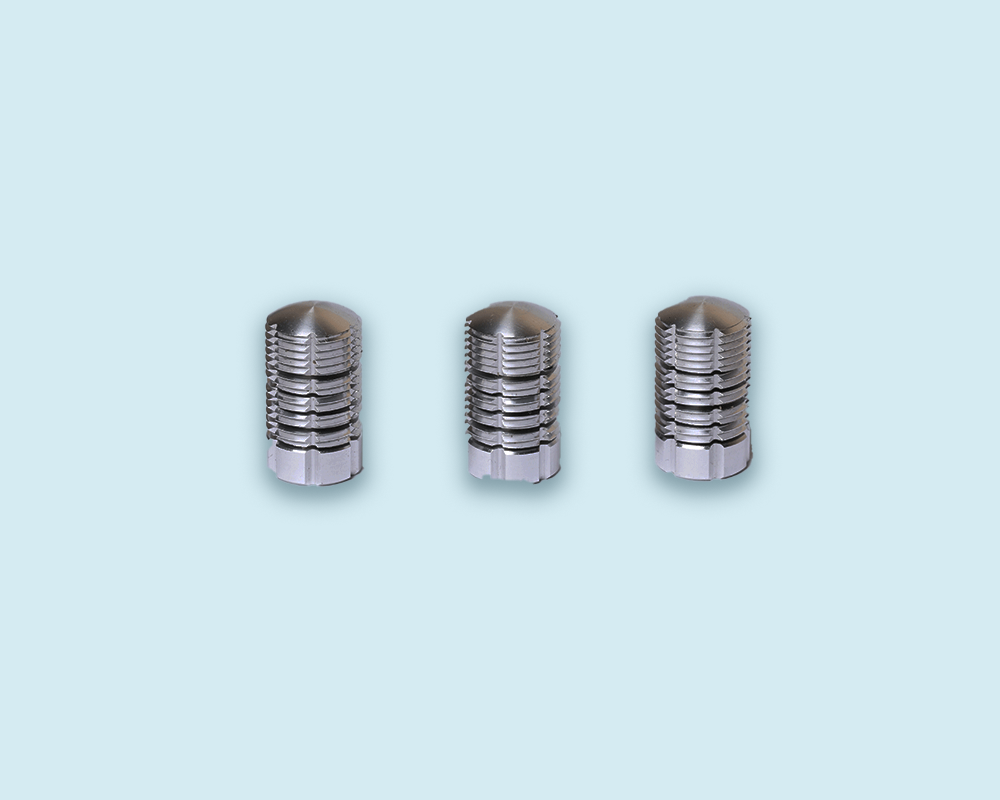

CNC Precision Machining for Automotive Spare Parts Production Automotive Part Manufacturing

In the automotive industry, the demand for high-quality spare parts continues to grow rapidly. To meet this demand, manufacturers are increasingly turning to CNC precision machining technology for the production of automotive spare parts.

Overview of CNC Precision Machining: CNC precision machining is a manufacturing process that utilizes computer-controlled machines to produce intricate and complex parts with high precision. This technology allows for the automation of various machining operations, resulting in improved accuracy, consistency, and efficiency in the production process. In the context of automotive spare parts production, CNC precision machining plays a crucial role in ensuring the quality and performance of the final products.

Application of CNC Precision Machining in Automotive Spare Parts Production: When it comes to producing automotive spare parts, CNC precision machining offers several advantages. One of the key benefits is the ability to create parts with tight tolerances and complex geometries, which are essential for ensuring proper fit and functionality in automotive applications. Additionally, CNC precision machining allows for the production of parts in a variety of materials, including metals, plastics, and composites, catering to the diverse needs of the automotive industry.

Furthermore, CNC precision machining enables manufacturers to optimize the production process by reducing lead times, minimizing material waste, and improving overall productivity. The automated nature of CNC machines also ensures consistent quality control throughout the manufacturing process, resulting in reliable and durable automotive spare parts.

Case Study: CNC Precision Machining for Automotive Brake Components, I have worked on numerous projects involving the production of automotive spare parts using CNC precision machining. One notable example is the manufacturing of brake components for a leading automotive manufacturer.

In this project, we utilized CNC machining to produce brake calipers, rotors, and pads with precise dimensions and smooth surface finishes. By programming the CNC machines to follow detailed blueprints and CAD models, we were able to achieve the desired specifications for each component, meeting the stringent quality standards of the automotive industry.

Through the integration of CNC precision machining technology, we were able to deliver high-quality brake components that met the performance requirements of our client. The use of CNC machines not only improved the efficiency of the production process but also enhanced the overall durability and reliability of the automotive spare parts.