19-inch rackmount enclosures are the industry standard for protecting a wide range of electronic equipment. These enclosures are not just mechanical housings; they play a vital role in ensuring system reliability, thermal management, electromagnetic shielding, and serviceability in critical infrastructure environments.

1. Introduction

The 19-inch format, defined by standards such as IEC 60297 and EIA-310, allows seamless integration of IT, power distribution, and control components in a wide range of industries. Choosing the right enclosure is essential to prevent overheating, ensure EMC compliance, and simplify maintenance.

2. Structural Design Considerations

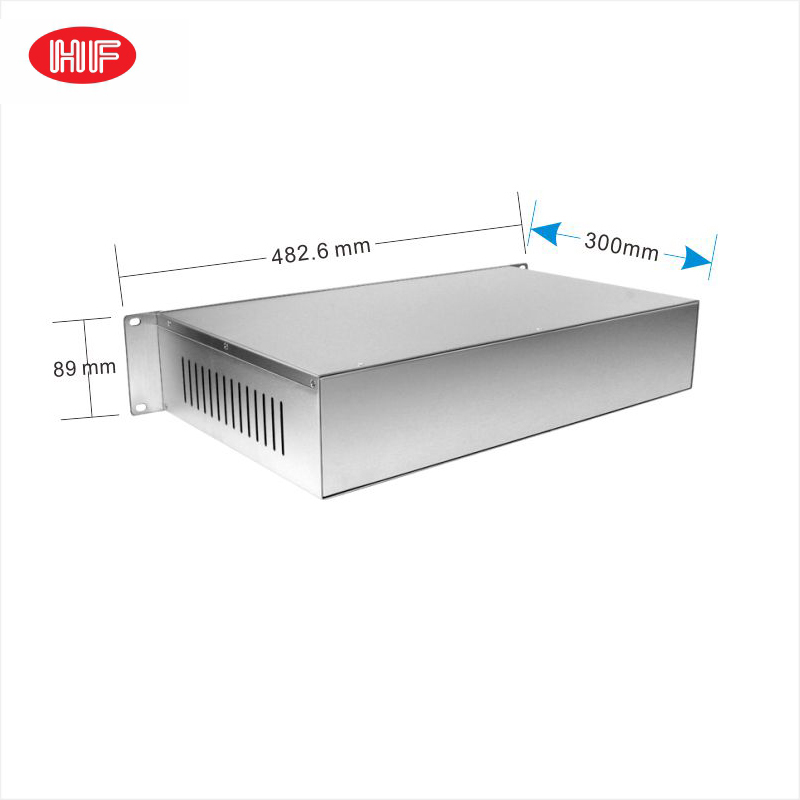

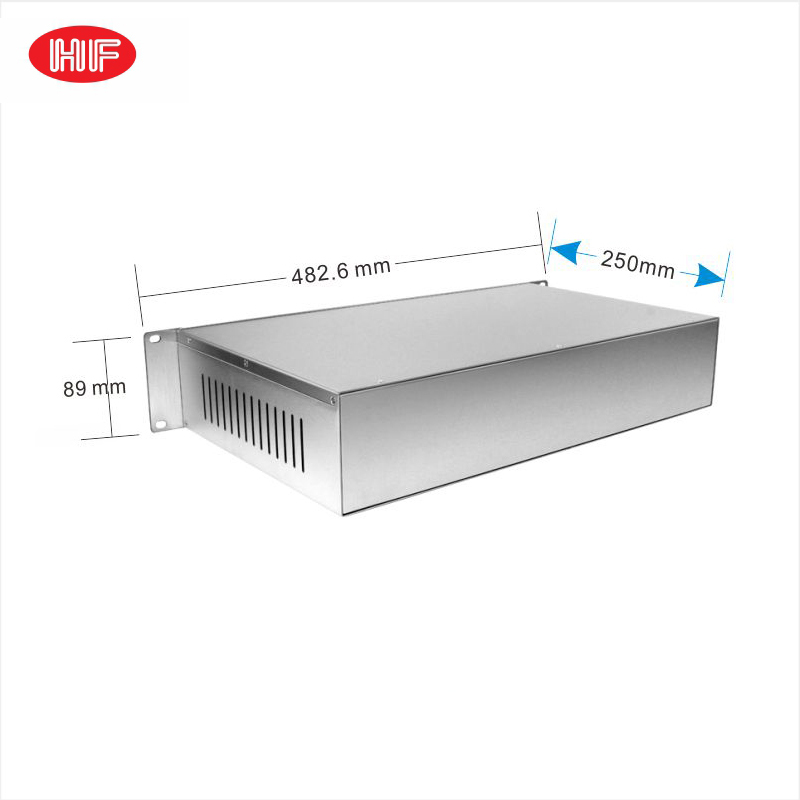

- Standard Dimensions: A 19-inch rackmount enclosure refers to the width of the equipment front panel, including mounting flanges. The standard unit height (U) is 1.75 inches. Common enclosures range from 1U to 12U and beyond.

- Material Selection: Aluminum, steel, and hybrid polymer-metal constructions are used based on strength-to-weight ratios, grounding requirements, and corrosion resistance.

- Load-Bearing Capacity: Industrial applications may require heavy-duty racks rated for 150 kg or more, especially for power-intensive installations.

3. Thermal Management

Thermal performance is a primary concern when housing high-density electronics.

-

- Passive Cooling: Strategic perforations and internal airflow channels help maintain convection-based heat dissipation.

- Active Cooling: Integrating fan trays, blower modules, and heat sinks in the enclosure ensures consistent thermal conditions in high-performance environments.

- Environmental Ratings: For industrial or outdoor use, NEMA or IP-rated rack enclosures with dust and moisture protection are critical.

4. Electromagnetic Compatibility (EMC)

- EMI Shielding: Proper grounding, conductive gaskets, and metal-to-metal contact points prevent signal interference and meet industry regulations.

- EMC Testing Compliance: Enclosures designed for medical or military applications must comply with EN 55032 or MIL-STD-461 standards.

5. Usability and Maintenance

- Front and Rear Accessibility: Tool-less front doors, hinged rear panels, and removable side covers facilitate easy access during installation and servicing.

- Cable Management: Integrated cable routing channels, brush strips, and tie-down points improve organization and airflow.

- Modular Design: Swappable trays, adjustable rails, and customizable cutouts make rackmount enclosures future-proof.

6. Application Scenarios

- Data Centers: Housing servers, switches, and patch panels with airflow optimization and redundancy.

- Industrial Automation: Protecting PLCs, HMIs, and motor drives in vibration-prone environments.

- Broadcast and AV Systems: Isolating sensitive equipment from external noise and enabling seamless equipment swaps.

7. Choosing the Right Manufacturer

Quality and reliability in rackmount enclosures depend heavily on the manufacturer’s engineering capabilities and certifications.

- Certifications: Look for ISO 9001, UL, and CE certifications for quality assurance.

- Customization Support: Manufacturers offering CNC machining, silk screening, and thermal analysis services provide value-added solutions.

- Lead Time and MOQs: Low minimum order quantities and fast prototyping are essential for startups and R&D departments.

A well-designed 19-inch rackmount enclosure can significantly enhance equipment reliability, ease of integration, and maintainability across a wide range of industries. By considering thermal, structural, and EMC aspects, professionals can future-proof their electronic systems. For more information or consultation on custom 19-inch rackmount enclosures, Email: vivian@hofengfab.com