Corte y conformado de metales

Presupuesto más rápido mediante carga de datos 3D

- Se adapta a diversos materiales y tratamientos de superficie Entrega más rápida en 1 día, incluso para 1 pieza

-Los archivos que cargue son estrictamente confidenciales y seguros

-Acomodación de plegados complejos y procesamiento láser de formas especiales

¿Qué es el plegado de chapa?

El plegado de chapa metálica es un proceso que consiste en ejercer fuerza sobre una chapa metálica para crear un radio deseado. Esta técnica ofrece la notable ventaja de poder moldear una amplia gama de geometrías de componentes sin necesidad de herramientas especializadas. La plegadora, una maquinaria habitual en este campo, se utiliza principalmente para lograr este objetivo.

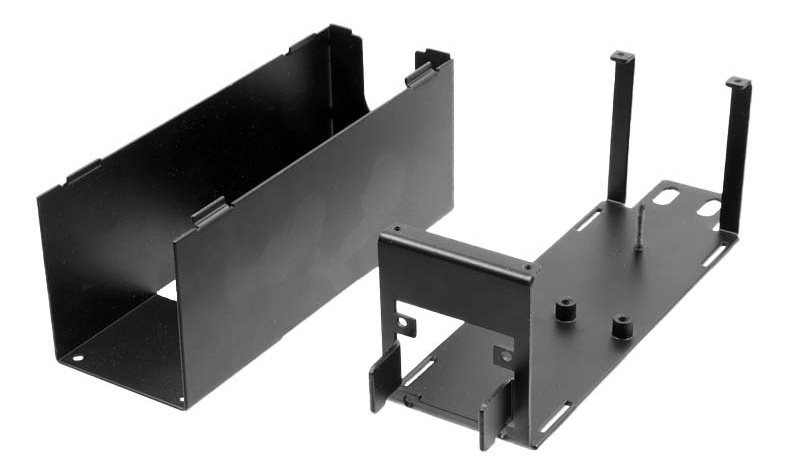

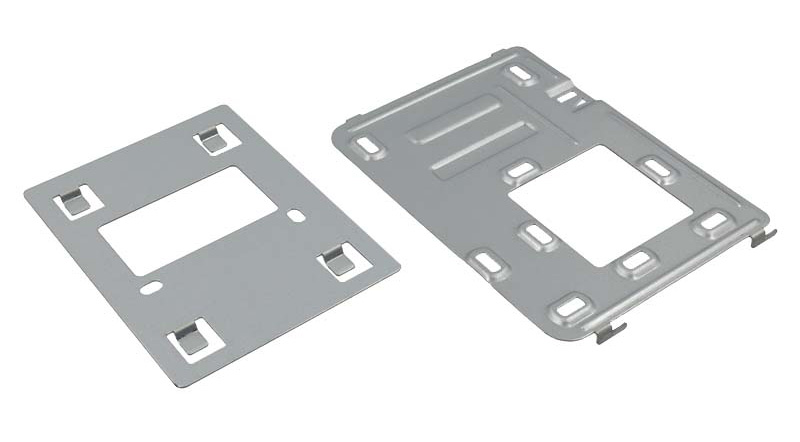

Las aplicaciones del plegado de chapa son amplias y diversas, y se extienden a la fabricación de numerosos productos industriales y de consumo. Por ejemplo, se emplea habitualmente en la fabricación de paneles de carrocería de vehículos, unidades de refrigeración, recintos electrónicos y soportes. Su versatilidad permite a los fabricantes crear diseños y formas complejas que no son fáciles de conseguir con otros métodos.

Además, el plegado de chapas metálicas es especialmente adecuado para situaciones que implican volúmenes de producción más bajos o el uso de chapas metálicas más finas. En estos casos, las técnicas de fundición pueden no ser rentables o prácticas, por lo que el plegado de chapa es una opción más viable. Esto es especialmente cierto para series de producción que oscilan entre varios cientos y varios miles de unidades por lote.

Servicios de curvado de tubos

El curvado de tubos consiste en una serie de procesos de fabricación que alteran la forma de un tubo o tubería para crear la geometría o las características deseadas que satisfagan requisitos específicos.HOFeng ofrece servicios de curvado y fabricación de tubos metálicos para satisfacer sus necesidades.

Cómo doblar chapas metálicas

1. El curvado de chapa suele realizarse con herramientas caras y especializadas conocidas como plegadoras. El curvado de chapa a mano es una tarea manejable si la pieza de chapa es lo bastante pequeña y fina para manipularla.

2.Doblado de tubos

Los métodos de curvado de tubos más utilizados son el curvado por prensado, el curvado por laminado, el curvado por retorno y el curvado por extrusión.

3.Curvado de perfiles

Los perfiles de los aviones se utilizan principalmente para fabricar esqueletos (alas del fuselaje y mamparos de entrada de aire, bordes de refuerzo, etc.), que se dividen en dos categorías: perfiles extruidos y perfiles de curvado de chapa. Los perfiles extruidos para laminación pueden dividirse en dos tipos: de curvatura igual y de curvatura variable. Las secciones de perfil más utilizadas son los perfiles angulares y los perfiles en forma de T.

Tipos de materiales para la fabricación de chapas metálicas

Nuestra empresa se especializa en la producción de componentes de chapa metálica, utilizando principalmente aluminio, acero inoxidable y aleaciones de acero como materiales principales. Estos metales ofrecen una excelente durabilidad, resistencia a la corrosión y solidez, lo que los hace ideales para diversas aplicaciones. También hemos acumulado una amplia experiencia en el trabajo con latón y bronce.Aluminio 5052, 5754, Acero inoxidable 304, 316L,Acero dulce 1018,Cobre C110

Acabado de superficies y montaje

"Acabado de superficies" se refiere a los procesos utilizados para mejorar el aspecto, la durabilidad de la superficie y la resistencia a la corrosión de un producto. Estas opciones de acabado incluyen el recubrimiento en polvo, el anodizado, el chapado, el pulido, el cepillado y otros. El acabado de superficies es esencial para mejorar la calidad general y la estética del producto final, así como para protegerlo de factores ambientales como el óxido y la corrosión.

Los "procesos secundarios" hacen referencia a operaciones o servicios adicionales que pueden ser necesarios una vez finalizado el proceso de fabricación inicial. Estos procesos secundarios pueden incluir actividades como el plegado CNC, el rectificado, el roscado, el moleteado y otras. Estos servicios son esenciales para conseguir las especificaciones y normas de calidad deseadas para el producto final.

Otras capacidades de fabricación

Estamos especializados en impresión 3D, mecanizado CNC, fundición en vacío, moldeo por inyección y fabricación de chapa metálica, ofreciendo una amplia variedad de materiales y acabados superficiales.

Mecanizado CNC

Disponemos de centro de mecanizado de composites fresado-torneado, 3 ejes estándar, 5 ejes continuos, fresadora de 3+2 ejes, taladrado y postprocesado utilizando más de 50 metales y plásticos diferentes, disponibles en más de 15 acabados superficiales. Tolerancias hasta ±.0000394" (0.001mm )

Servicios de moldeo por inyección

Hofengfab puede moldear cualquier termoplástico. Servicios de moldeo por inyección rentables para sus productos y piezas personalizados. Herramienta prototipo en tan solo 10 días Herramienta de producción en tan solo 2 semanas, ISO 9001:2015 | Crítico para inspecciones de calidad.

Servicio de impresión 3D

El servicio de impresión 3D de Hofengfab es su centro de producción de fabricación aditiva para más de 30 materiales para cualquier aplicación, servicio de impresión 3D Somos expertos en impresión 3D para satisfacer todas sus necesidades de grado industrial.

Servicios de fundición de uretano

Haciendo para la creación rápida de prototipos y la producción de piezas,Piezas tan rápido como 10 días,100% inspección para cada part.Our ISO 9001 Certified entregar calidad de grado con cada batch.We son los expertos en materiales de poliuretano en su desarrollo de productos