Presupuesto más rápido cargando datos 3D

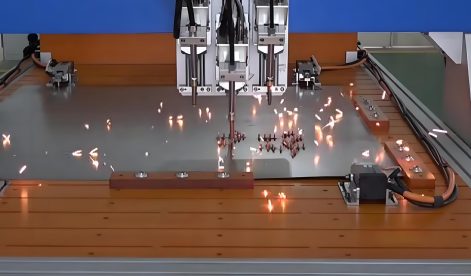

Corte y conformado de metales

- Adaptación a plegados complejos y procesamiento láser de formas especiales

- Se adaptan a diversos materiales y tratamientos superficiales La entrega más rápida en 1 día, incluso para 1 pieza

Los archivos que cargue son estrictamente confidenciales y seguros

Servicio de corte y conformado de metales

Trabaje con diversos métodos de procesamiento y formas especiales, como corte por láser, punzonado y anidado CNC, plegado y pulverización.

Trabaje con diversos métodos de procesamiento y formas especiales, como corte por láser, punzonado y anidado CNC, plegado y pulverización.

Trabajar con diversos materiales, como acero inoxidable, acero al carbono y aleaciones de aluminio.

Capaz de identificar automáticamente los tipos de orificios.

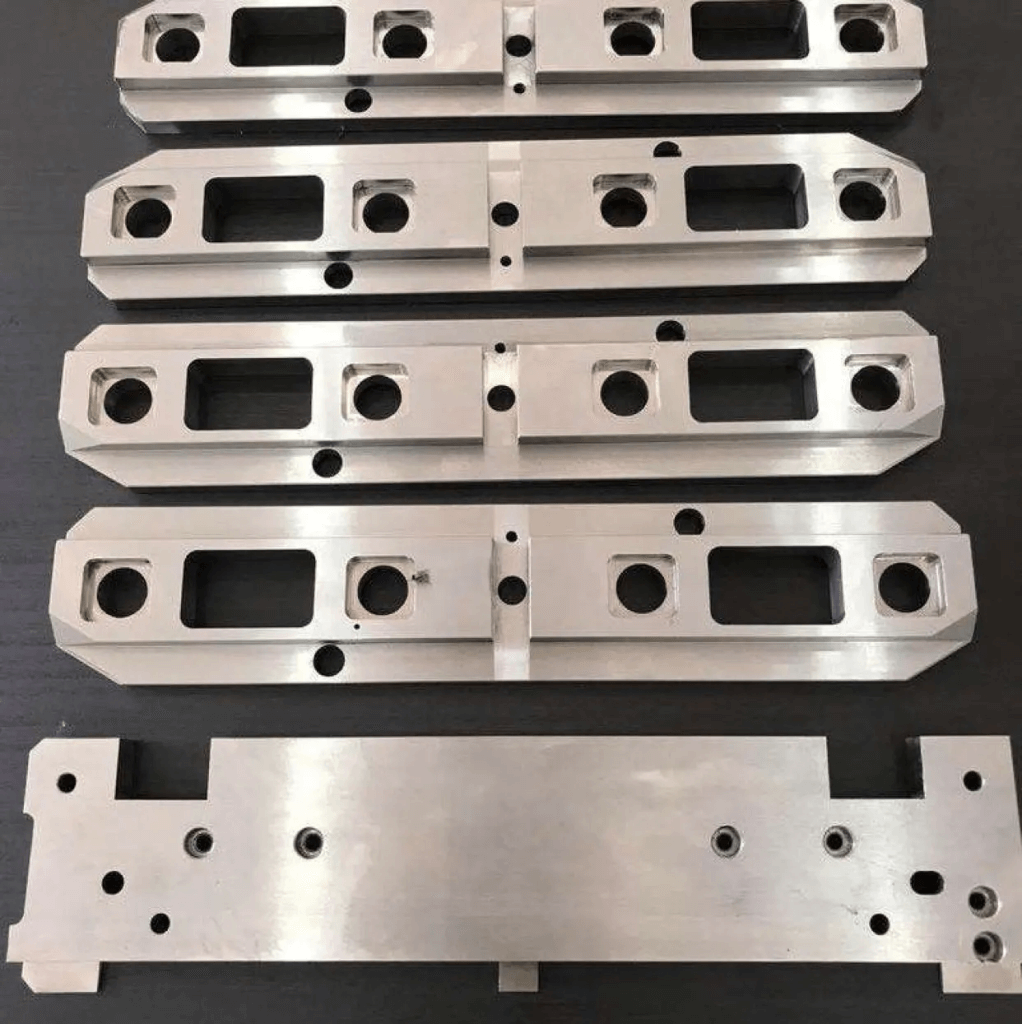

Capacidad de fabricación de chapas metálicas

HOFeng está equipada con soldadura CO2 robotizada, pulido robotizado, soldadura láser robotizada, soldadura láser de plataforma, cortadora láser, soldadura láser manual, punzonadora CNC, plegadora, desbarbadora automática para mejorar la velocidad y la capacidad de hacer frente a las aplicaciones de producción en masa.

grandes fabricantes de chapa

Transformación de chasis y armarios de chapa

Décadas de experiencia en la fabricación de chapas metálicas

Si busca un fabricante de chapas metálicas que pueda encargarse de todo, desde el desarrollo de nuevos productos y piezas prototipo hasta grandes series de producción y servicios de montaje, HOFeng está por encima de lo que usted espera.Nuestros expertos gestionan cada paso del proceso, desde la asistencia en el diseño y la fabricación metálica hasta la pintura, la serigrafía, el kitting y el montaje.

Punzonado CNC

Nuestras punzonadoras CNC pueden procesar con precisión características estándar y formas complejas en chapa metálica para satisfacer sus necesidades. La punzonadora de torreta que empleamos puede punzonar hasta un grosor de 1/4 de pulgada y también podemos producir características especiales como avellanados, rebordes y rejillas.

plegado de chapa

ISO9001

Plazo de entrega de un día

Aluminio, acero, acero inoxidable y más

La máquina curvadora de chapa se utiliza principalmente para curvar la chapa en línea recta. El proceso de plegado en prensa se utiliza principalmente para el procesamiento de piezas con grandes lotes de producción, formas complejas y requisitos de alta precisión.

Proporcione ángulos precisos con nuestros servicios de plegado, consiguiendo un producto final que se ajusta a tolerancias ajustadas.

servicio de corte por láser fabricación de chapa

El corte por láser utiliza un potente láser que se intensifica a través de lentes o espejos. Es una máquina precisa y de bajo consumo adecuada para chapas finas o de calibre medio, pero puede tener dificultades para penetrar en los materiales más duros.

Corte por chorro de agua

El corte por chorro de agua es un método de fabricación de chapas metálicas que utiliza un chorro de agua a alta presión (mezclado con una sustancia abrasiva) para cortar metal. El servicio de corte por chorro de agua de HOFeng es una solución versátil y rentable para piezas metálicas de precisión cortadas con un alto grado de exactitud.Nuestras máquinas de chorro de agua de gran formato pueden cortar materiales de hasta 6 pulgadas de espesor con una tolerancia de 0,005″- 0,015″.

Corte por plasma CNC

El corte por plasma es más eficaz para el corte de metales no ferrosos (acero inoxidable, aluminio, cobre, titanio, níquel); su principal ventaja es que al cortar metales de pequeño espesor, la velocidad de corte por plasma es rápida, especialmente al cortar chapas finas de acero al carbono ordinario.El servicio de corte por plasma de HOFeng puede proporcionar piezas complejas de alta precisión en materiales como aluminio, acero y acero inoxidable.

Electroerosión por penetración y por hilo

La electroerosión por penetración utiliza descargas eléctricas para erosionar la superficie de la pieza y crear las formas deseadas. Por otro lado, la electroerosión por hilo utiliza un alambre fino para cortar la pieza y es adecuada para el mecanizado de formas complejas y de alta precisión. Ayuda a cumplir los requisitos de alta precisión en la fabricación de piezas de trabajo y mejora la eficacia de la producción.

Variedad de métodos de soldadura

HOFeng dispone de cuatro técnicas principales de soldadura: TIG (gas inerte de tungsteno), MIG (gas inerte metálico), MAG (gas activo metálico) y soldadura con CO2. Cada uno de estos métodos ofrece ventajas únicas y es adecuado para diferentes aplicaciones de soldadura, que van desde la soldadura de precisión a la fabricación de alta resistencia.

Acabado de superficies y montaje

"Acabado de superficies" se refiere a los procesos utilizados para mejorar el aspecto, la durabilidad de la superficie y la resistencia a la corrosión de un producto. Estas opciones de acabado incluyen el recubrimiento en polvo, el anodizado, el chapado, el pulido, el cepillado y otros. El acabado de superficies es esencial para mejorar la calidad general y la estética del producto final, así como para protegerlo de factores ambientales como el óxido y la corrosión.

Los "procesos secundarios" hacen referencia a operaciones o servicios adicionales que pueden ser necesarios una vez finalizado el proceso de fabricación inicial. Estos procesos secundarios pueden incluir actividades como el plegado CNC, el rectificado, el roscado, el moleteado y otras. Estos servicios son esenciales para conseguir las especificaciones y normas de calidad deseadas para el producto final.

Materiales para la fabricación de metales

Otras capacidades de fabricación

Estamos especializados en impresión 3D, mecanizado CNC, fundición en vacío, moldeo por inyección y fabricación de chapa metálica, ofreciendo una amplia variedad de materiales y acabados superficiales.

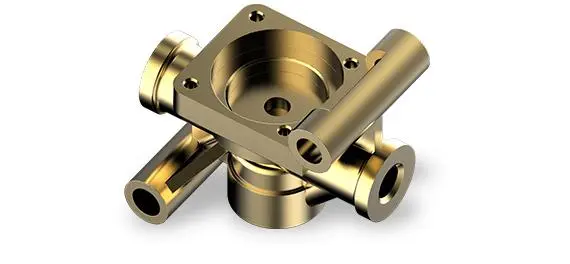

Mecanizado CNC

Disponemos de centro de mecanizado de composites fresado-torneado, 3 ejes estándar, 5 ejes continuos, fresadora de 3+2 ejes, taladrado y postprocesado utilizando más de 50 metales y plásticos diferentes, disponibles en más de 15 acabados superficiales. Tolerancias hasta ±.0000394" (0.001mm )

Servicios de moldeo por inyección

HOFeng puede moldear cualquier termoplástico. Servicios de moldeo por inyección rentables para sus productos y piezas personalizados. Herramienta de prototipo en tan pronto como 10 días Herramienta de producción en tan pronto como 2 semanas, ISO 9001:2015 | Crítica a las inspecciones de calidad.

Servicio de impresión 3D

El servicio de impresión 3D de HOFeng es su centro de producción de fabricación aditiva para más de 30 materiales para cualquier aplicación, servicio de impresión 3D Somos expertos en impresión 3D para satisfacer todas sus necesidades de grado industrial.

Servicios de fundición de uretano

Haciendo para la creación rápida de prototipos y la producción de piezas,Piezas tan rápido como 10 días,100% inspección para cada part.Our ISO 9001 Certified entregar calidad de grado con cada batch.We son los expertos en materiales de poliuretano en su desarrollo de productos

Por qué elegir HoFeng

Precisión y exactitud

1. Nuestras máquinas de precisión y nuestro software de última generación garantizan la precisión y coherencia de cada producto que creamos.

2. Los estrictos procesos de control de calidad garantizan que todos los productos cumplan nuestras estrictas normas y se ajusten exactamente a las especificaciones.

Respuesta rápida

1. Equipo de ingeniería y operaciones experimentado

2. Taller mecánico propio, operativo 24 horas al día, 7 días a la semana

3. La alta calidad es nuestra máxima prioridad.

4. Ayudarle con presupuestos, producción y entrega instantáneos

Garantía de calidad

1. Nuestro sistema de gestión de la calidad con certificación ISO 9001 garantiza la fiabilidad

2. Todas las piezas se comprueban dimensionalmente con equipos calibrados para que cumplan sus especificaciones exactas.

3.Más de 250 proyectos Entregado por mes,10000+SQ ÁREA DEL METRO, 15+ AÑOS DE SERVICIO