Prototype Sheet Metal Fabrication Services

HOFeng can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes

NO MOQ (minimum order quantity)

100% inspection for every part

The files you upload are strictly confidential and secure

Applications for Sheet Metal Fabrication

We have over 60 CNC Machines in our factory

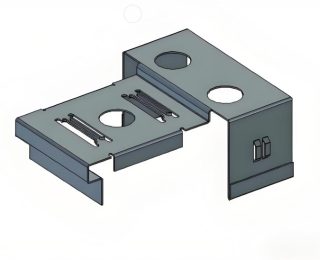

Sheet Metal Prototypes

Sheet Metal Prototypes

Whether you need a

bracket, chassis

enclosure, or any other

complex sheet metal

design, we can meet your needs

Sheet Metal Products

Sheet Metal Products

Our low-volume production

facility can produce up to

60 to 1500+sheet metal

parts in as fast as 10 days.

Multipart Assemblies

With our experienced staff and rigid quality protocols we can guarantee that Sheet Metal Products will deliver a conforming finished product the first time.

Sheet Metal Prototyping Materials-Sheet Metal Fabrication China

As a leading sheet metal fabricator in China, HOFeng has 15 years of experience in sheet metal fabrication, helping you provide high-quality precision metal products at competitive prices.HOFeng offers a variety of sheet metal fabrication materials, including stainless steel, aluminum, copper, brass, and galvanized steel, and we can help clients choose the right one for their prototyping projects.

what is sheet metal prototyping

Sheet metal processing is a method of cold and hot forming, assembly, and connection of metal plates, profiles and pipes to manufacture metal components by welding, riveting and bolting. It mainly involves benchwork, stamping, metal cutting, welding, heat treatment, surface treatment, riveting, assembly and other professional types of work.

HOFeng Comprehensive Prototyping Capabilities

Our factory covers an area of 6,000+ square meters, with complete hardware and software facilities, including more than 60 punching machines, 30 CNC machining centers, 3 laser cutting machines, and several CNC bending machines.We have machines involves Cutting, Bending, Punching, Drilling, Welding and Forming. The company is equipped with many experienced precision mold development and CNC programming designers, and all products comply with ROHS directive standards.Our machinery can efficiently remove burrs and sharp edges, Precision Grinding,Wide Belt Sanding,enhancing the safety and aesthetics of your sheet metal components,ensuring that your sheet metal products meet the highest standards.

In addition, we offer a variety of finishes, including powder coating, plating, and anodizing. We also offer dedicated laser cutting,

Water Jet Cutting,Wire EDM,Photo Chemical Etching,punching, and forming services. Our team of skilled engineers and technicians is dedicated to providing our customers with the highest quality parts and excellent customer service. Whether you need a few prototypes or a low volume production run, we are your one-stop for all your sheet metal fabrication needs. Contact us today for a free quote!

Sheet Metal Finishing process

1.Standard Finish

Grinding and Polishing

Brushing

2. Bead Blasting

3. Anodizing

Anodize (type II or type III)

Chromate

Zinc

Passivate

Electroless Nickel

Tin

Class 1 refers to un-dyed and Class 2 refers to dyed

coatings. Although black is the most popular Type 2

anodization, there are clear, blue, red, gold, yellow,

orange, green, purple,

and other pigments available.

Class 1 refers to a clear hard coat whereas Class 2 refers to

a black hard coat.

4. Chemical Film Coating

5.Powder Coating

6. PlatingPlating (or coating) options can provide corrosion resistance, improve wear properties, and help with conductivity while enhancing appearance with a quality, uniform finish.

Available plating options include:

Anodize (type II or type III)

Chromate

Zinc

Passivate

Electroless Nickel

Tin

7. Silk Screening

This process is often used for adding labels, instructions, or decorative patterns to fabricated metal products.

8. Shot Peening 9 Assembly and kitting

Our Other Manufacturing Capabilities

We Specialize In 3D Printing, CNC Machining, Vacuum Casting, Injection Molding And Sheet Metal Fabrication, Offering A Wide Variety Of Materials And Surface Finishes.

CNC Machining

We have Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0000394" (0.001mm )

Injection Molding Services

HOFeng can mold any thermoplastic. Cost-effective injection molding services for your custom products and parts. Prototype Tool In Soon As 10 Days Production Tool In As Soon As 2 Weeks, ISO 9001:2015 | Critical to Quality Inspections

3D Printing Service

HOFeng's 3D Printing Service is your additive manufacturing production center for 30+ materials for any application,3D printing service We Are 3D Printing Expert To Meet Your All Requirements Industrial-Grade.

Urethane Casting Services

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part.Our ISO 9001 Certified deliver grade quality with every batch.We are the polyurethane material experts in your product development

You ask, we answer

Sheet Metal Fabrication Services

Sheet Metal Prototyping can accelerate your project’s development with its swift, flexible, and reliable design iterations, testing functionality, and shift from concept to market with speed.