Polyjet 3d printing service

Making for rapid prototyping and production of parts,Parts as fast as 10 days,100% inspection for every part

Our ISO 9001 Certified deliver grade quality with every batch

- No minimum order quantity

- Rapidly-made in a Few Days

- Rapid Prototyping and Full Production Runs

- Over 30+ Metal and Plastic Materials Available

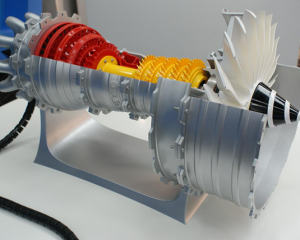

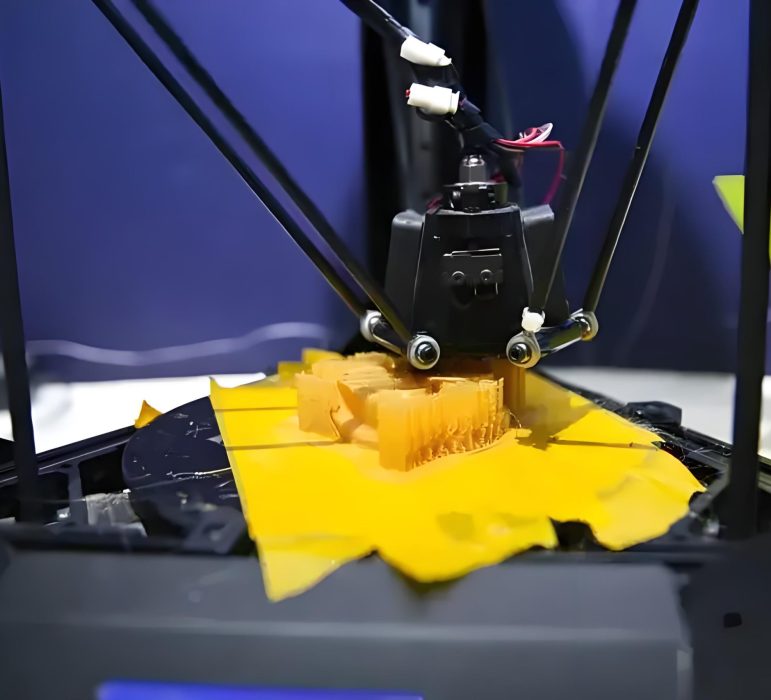

What PolyJet 3D Printing Makes Possible

Fast Part Production // PolyJet offers relatively fast printing speeds, especially for smaller build volumes. This allows for rapid prototyping and quick turnaround times, enabling designers and engineers to iterate and refine their designs more efficiently.

No Post-Curing Required // Unlike some other 3D printing technologies, PolyJet parts do not require additional curing steps after printing. The UV curing process during printing ensures that the material is fully solidified and ready to use immediately.

Easy Support Structure Removal: // PolyJet uses a gel-like support material that can be easily removed using a water jet or similar method. This eliminates the need for manual support structure removal, saving time and effort.

High Precision and Detail// PolyJet's precision jetting technology enables the creation of highly detailed and smooth-surfaced parts. This makes it suitable for applications that require intricate geometries and fine details, such as medical models and consumer products.

Multi-Material Capability// PolyJet's ability to print with multiple materials simultaneously allows for the creation of parts with varying properties and aesthetics. This versatility enables designers to create prototypes and products that more closely resemble their final form and function.

Industries where PolyJet parts are used include//Medical,Dental,Consumer products

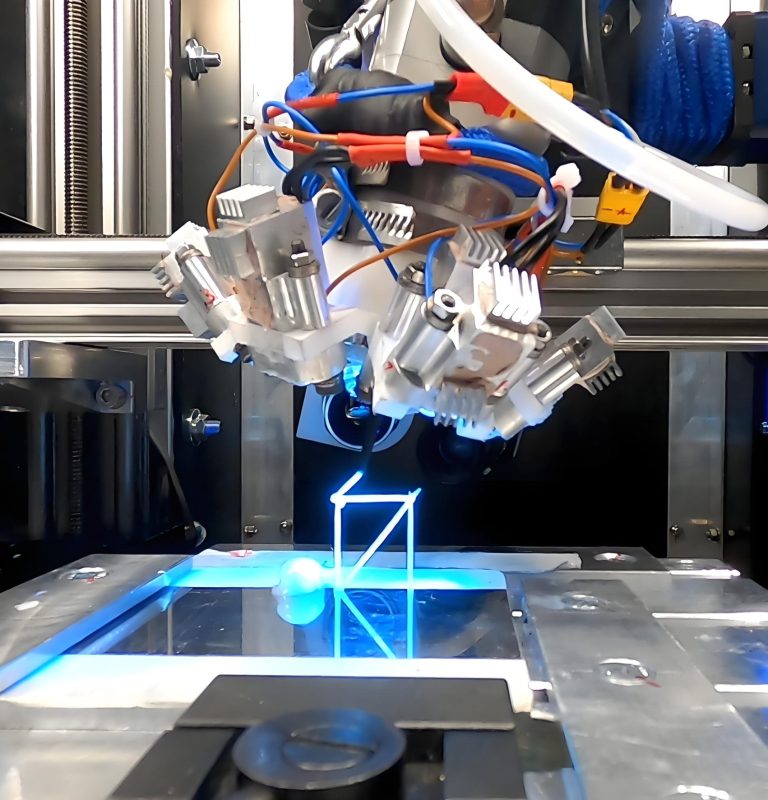

How Does PolyJet Work?

PolyJet technology revolutionizes the 3D printing industry by offering a unique photopolymer-based jetting process. Here's a more detailed explanation of how PolyJet works:

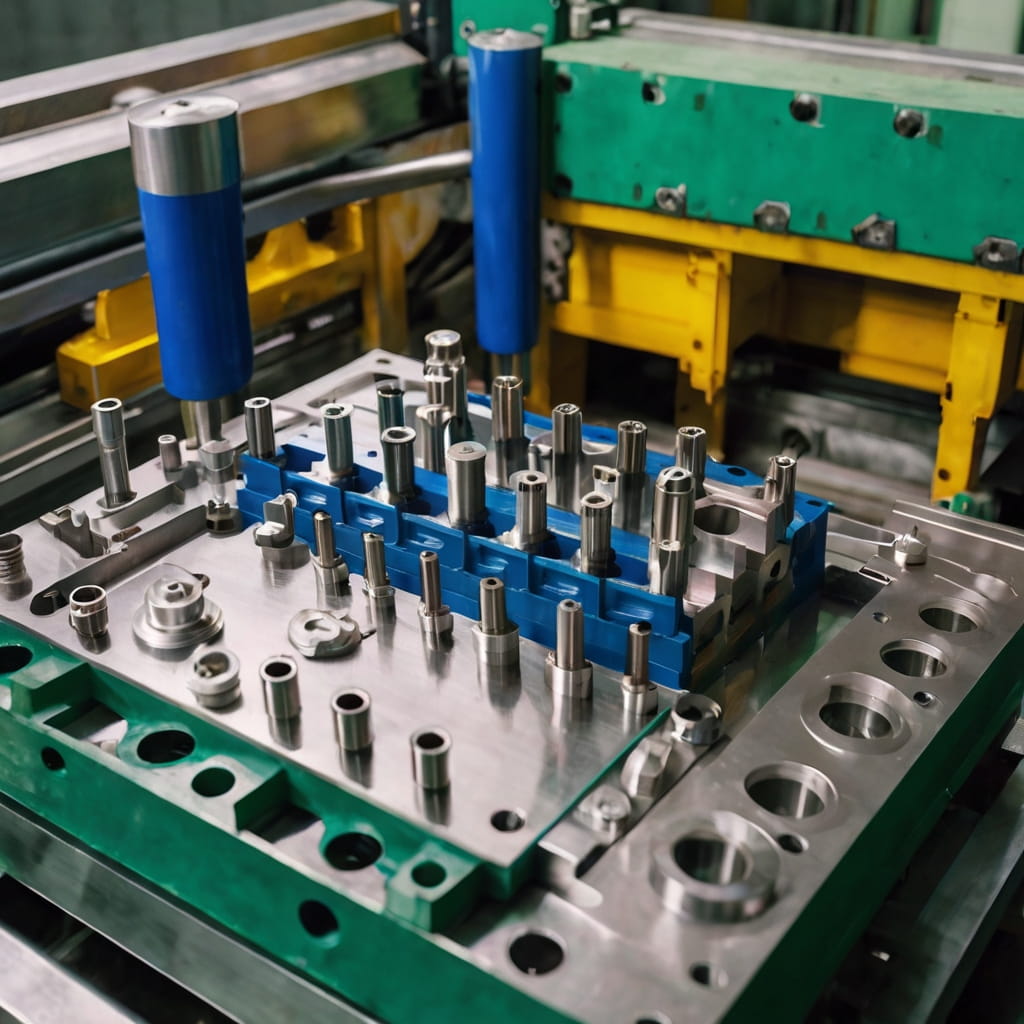

1. Material Jetting //PolyJet uses inkjet-like print heads to precisely distribute fine droplets of photopolymer material onto a build platform. These droplets are jetted layer-by-layer, gradually building up the desired 3D object.

2. UV Curing //Immediately after the material droplets are deposited, a flash of UV (ultraviolet) light is applied to cure (or solidify) the material. This rapid curing process ensures that each layer is firmly adhered to the previous one, creating a strong and stable structure.

3. Multi-Material Capability //PolyJet's advanced capabilities allow it to print with multiple materials simultaneously. This includes the ability to print with different colors, textures, and material properties, all within the same print job. This versatility enables the creation of highly detailed and realistic prototypes, models, and even end-use parts.

4. Support Material //To support overhangs and intricate geometries during the printing process, PolyJet uses a gel-like support material. This material is easily removable using a water jet or similar method, eliminating the need for manual support structure removal.

5. Fine Detail and Smooth Surfaces //PolyJet's precision jetting technology enables it to achieve ultra-fine details and smooth surfaces. By combining photopolymers in different concentrations and structures, PolyJet can simulate various materials, such as plastics, rubber, and more, with realistic textures and patterns.

6. Post-Processing //Once the build process is complete, the printed part is ready for use with minimal post-processing required. The support material can be easily removed, and any remaining surface imperfections can be smoothed out using standard finishing techniques if desired.

PolyJet 3D Printing industries with Advanced Applications

PolyJet material jetting technology is suitable for a wide range of applications across various industries, creating accurate, visually stunning models from prototyping to low-volume production without the need for tooling.

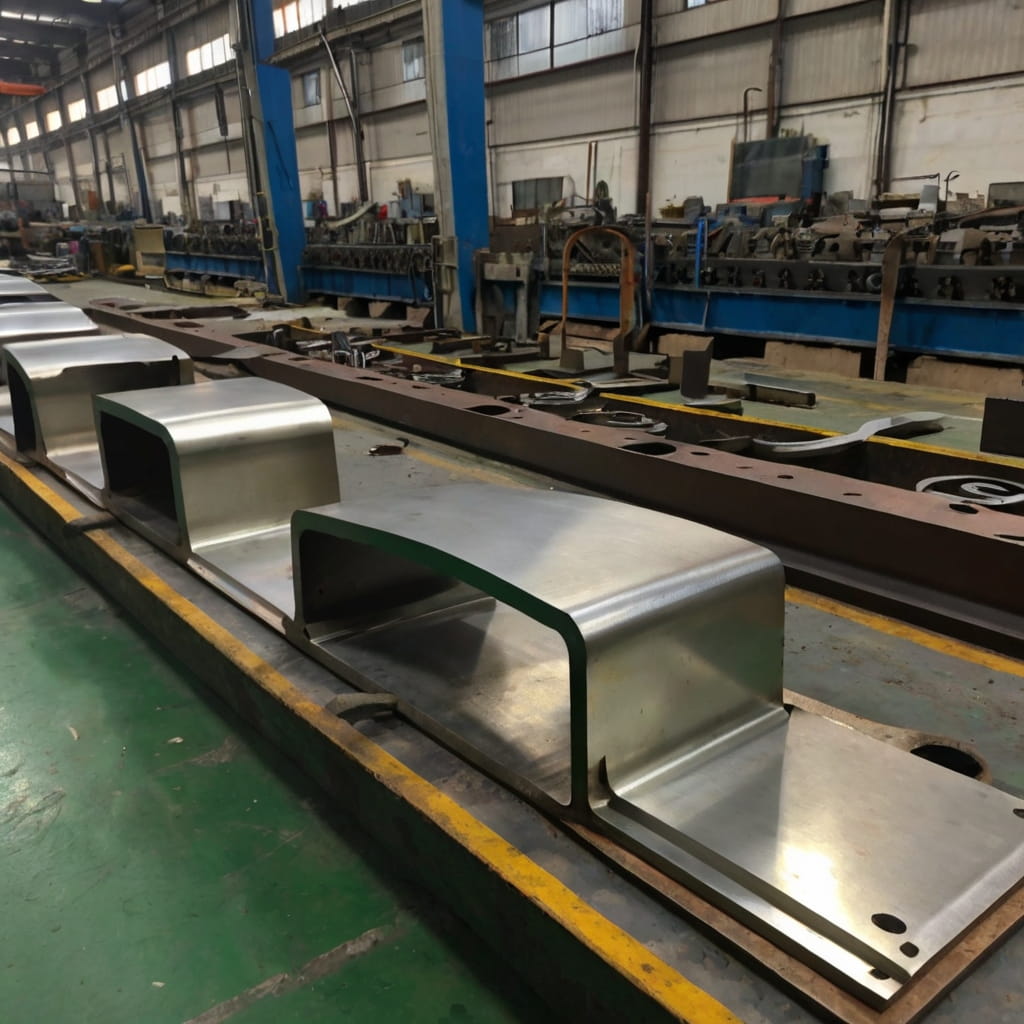

PolyJet can benefit CNC machining prototype parts:

Faster Turnaround Times//CNC machining often involves extensive machine setup, tool changes, and post-processing steps, which can lead to longer lead times. PolyJet, on the other hand, can print prototype parts in a matter of hours, significantly reducing turnaround times.

Complex Geometries and Details//While CNC machining can achieve high precision, it can be challenging to machine complex geometries and intricate details. PolyJet's precision jetting technology enables the printing of highly detailed and smooth-surfaced parts, making it ideal for prototypes that require intricate designs.

Material Versatility//PolyJet offers a wide range of photopolymer materials that can simulate different material properties, including rigid, flexible, transparent, and even multi-color options. This versatility allows for the creation of prototypes that closely resemble the final product in terms of appearance, feel, and functionality.

Cost-Effectiveness for Low-Volume Production//For low-volume prototype production, CNC machining can be costly due to the setup time and material waste. PolyJet, on the other hand, can produce multiple prototype parts simultaneously with minimal material waste, making it a more cost-effective solution for low-volume production runs.

Design Iteration and Testing//

PolyJet's fast printing speed allows for quick design iterations and testing.

It's worth noting that PolyJet 3D printing is not a replacement for CNC machining in all cases. CNC machining remains the preferred choice for high-volume production runs and parts that require extreme precision or durability. However, for rapid prototyping and low-volume production, PolyJet offers a faster, more versatile, and cost-effective alternative.

PolyJet 3D printing advantages

Versatility and Speed//PolyJet 3D printing excels in its versatility, from prototypes and colorful models to end-use parts.Its fast printing speeds enable designers and engineers to iterate and refine their designs more quickly.

Excellent Level of Detail//PolyJet technology can print layers as thin as 16 microns, resulting in incredibly detailed and smooth-surfaced parts.

This level of precision enables the creation of intricate geometries and fine details.

Support for Digital Materials//PolyJet printers offer the unique ability to mix up to six resins during the printing process.

Transparent Options//PolyJet 3D printing can produce transparent and translucent materials, enabling the creation of visually appealing and functional parts.

This capability is particularly useful for applications that require see-through parts, such as windows, containers, and other visual components.

Fast Removal of Support Material//PolyJet uses a gel-like support material that can be easily removed using a water jet.

This rapid support material removal process eliminates the need for manual support structure removal, saving time and effort while maintaining a smooth and clean part finish.

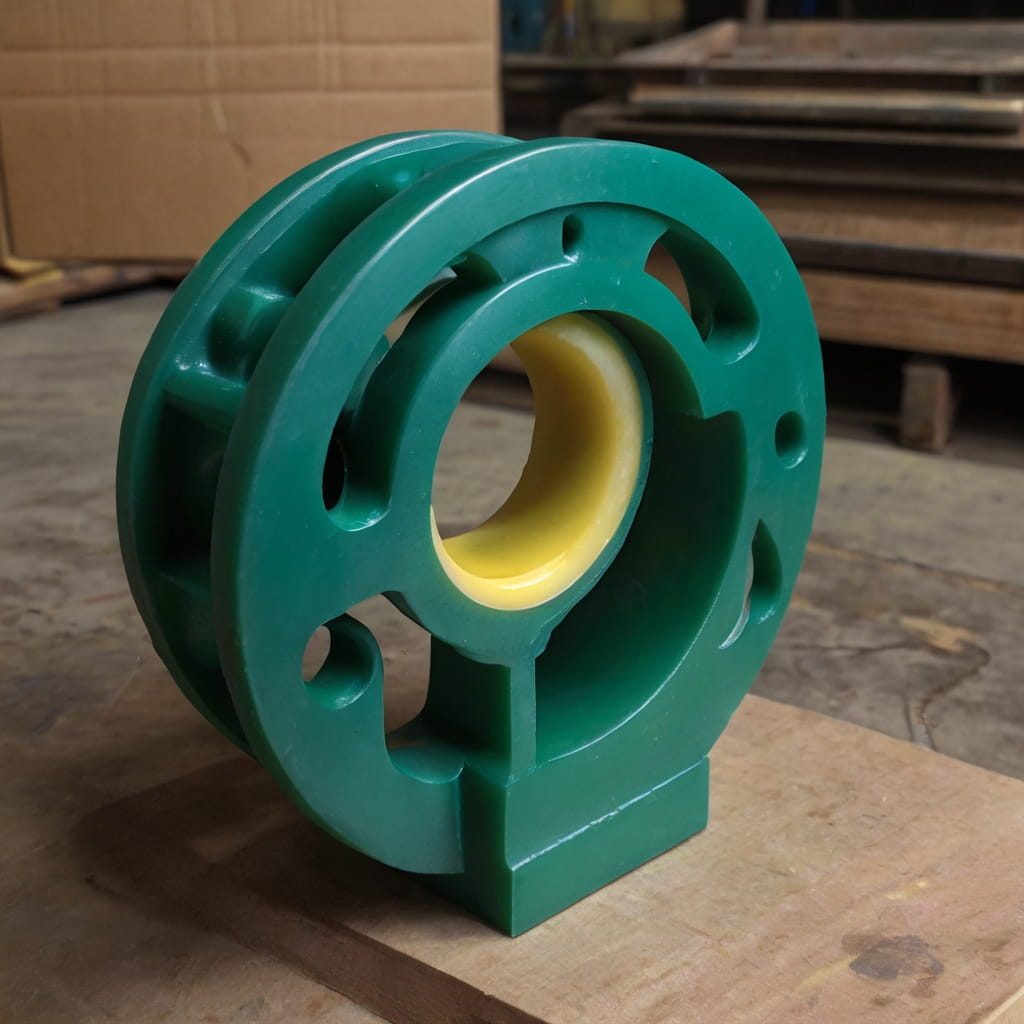

Strong Parts//PolyJet 3D printing produces sturdy and durable parts with good tensile strength.This makes PolyJet parts suitable for a wide range of applications, including prototypes, functional models, and even some end-use parts that require durability and strength.

PolyJet 3D Printing Disdvantages

Cost//PolyJet printers and their materials tend to be more expensive than some other types of 3D printing technologies.

The specialized photopolymers used in PolyJet printing can have a higher cost per gram, which can add up significantly for larger or more complex prints.

Part Size Limitations//PolyJet 3D printing is generally not suitable for printing larger parts due to the build volume limitations of the printer.

This can be a constraint for applications that require larger-scale prototypes or end-use parts.

Support Structure//While PolyJet uses a gel-like support material that can be easily removed, the addition of support structures can contribute to longer total part printing times.

The need to print support structures can also increase material usage and add complexity to the printing process.

Not for Long-term Use//Photopolymers used in PolyJet printing may not be suitable for long-term use in harsh environments or conditions.

Exposure to heat, sunlight, and humidity can cause photopolymers to degrade, leading to a loss of strength and durability over time.

How can we help you?

HOFeng employs advanced manufacturing capabilities to create precision parts. Check how our processes to achieve your project.