Why put up with the headaches of returns, delays and shipping errors that disrupt production schedules, damage customer relationships and cost you money?

HOFengfab's rigorous quality assurance procedures guarantee that you always get the parts you order.

0.5 to 3

±0.05

±0.1

±0.2

–

More than 3 to 6

±0.05

±0.1

±0.2

–

More than 6 to 30

±0.05

±0.1

±0.2

–

More than 30 to 120

±0.05

±0.1

±0.2

–

More than 120 to 400

±0.05

±0.1

±0.2

–

More than 400 to 1000

±0.05

±0.1

±0.2

–

More than 1000 to 2000

±0.05

±0.1

±0.2

–

0.5 to 3

±0.05

±0.1

±0.2

–

More than 3 to 6

±0.05

±0.1

±0.2

–

More than 6 to 30

±0.05

±0.1

±0.2

–

More than 30 to 120

±0.05

±0.1

±0.2

–

More than 120 to 400

±0.05

±0.1

±0.2

–

More than 400 to 1000

±0.05

±0.1

±0.2

–

More than 1000 to 2000

±0.05

±0.1

±0.2

–

Quality control measures involve systematic processes and checks to ensure that products or services meet specified standards and customer requirements, with the goal of minimizing defects and maintaining consistent quality.

Our quality control pre-production assessments include technical and material validation. Our experts evaluate material selection, part structure, and production processes. We assess potential risks and determine whether requirements can be achieved during the initial development phase.

Verify that the material is consistent with the production plan. Material certification is available upon request. It provides detailed information on grade, heat number, chemical composition, dimensions and material properties.

Hofengfab performs in-process quality control in accordance with our ISO9001:2015 program. First Article Inspection is a routine inspection completed every two hours on the production line.

Before an injection molding project goes into production, a First Article Inspection is required. Upon request, First Article Inspection is also available for CNC machining projects. The First Article Inspection process includes an in-depth inspection with images of the part.

Includes dimensional report and certificate of proper packaging. Inspection reports are available upon request. They provide a detailed analysis of part counts, critical dimensions, depths, thicknesses, tolerances, threads and other essential qualifications. We guarantee that all parts are packaged to prevent damage during shipping.

Hofengfab will issue a certificate of conformity certifying that the order has been shipped to the required specifications. Quality reports are available for Injection Molding, Die Casting, Stamping and CNC Machining processes.

Hofengfan will issue a certificate of conformity certifying that the order has been shipped to the required specifications. Quality reports are available for Injection Molding, Die Casting, Stamping and CNC Machining processes.

Hofengfabwill issue a certificate of conformity certifying that the order has been shipped to the required specifications. Quality reports are available for Injection Molding, Die Casting, Stamping and CNC Machining processes.

Hofengfab will issue a certificate of conformity certifying that the order has been shipped to the required specifications. Quality reports are available for Injection Molding, Die Casting, Stamping and CNC Machining processes.

Our Part Verification Program is standard procedure for injection molding projects and can best be described as an upgraded first article inspection. It is available for CNC machining projects with a minimum unit quantity of 100.

The program provides for two sets of parts to be shipped to the customer for testing. Once the project is approved, it will go into production. At this stage, design changes can be easily made by submitting revised drawings to us. If the changes are major, the changes will increase the price.

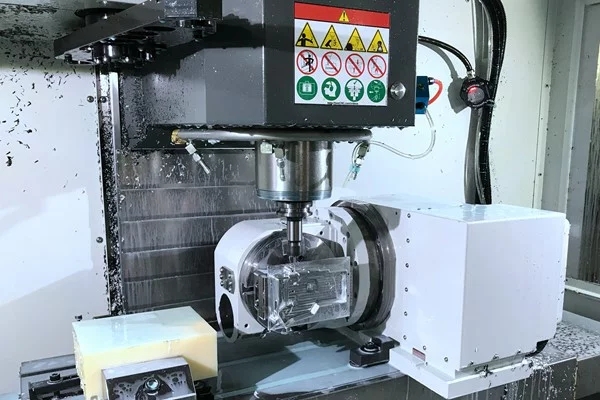

Hofengfab uses coordinate measuring machines for prototyping and to verify the dimensions of produced parts. A coordinate measuring machine captures a series of points on an object and determines the dimensions of the object. CMMs are ideal for complex geometries.

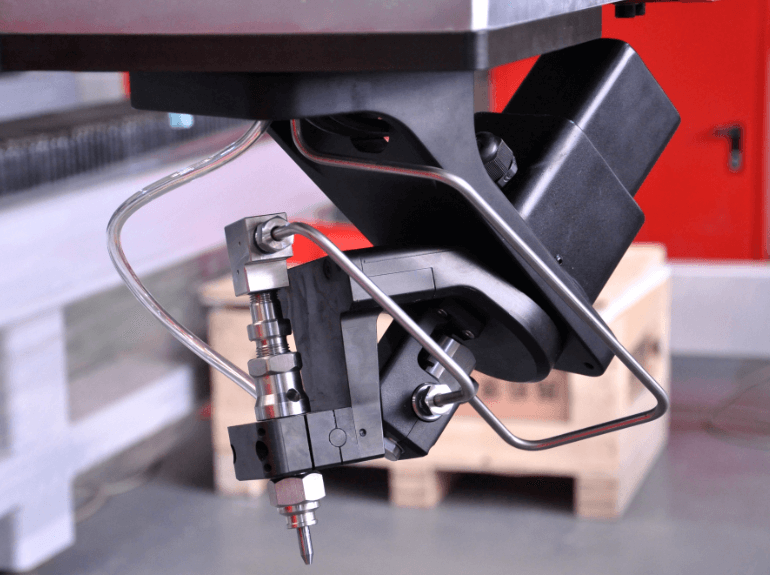

A projector is also called an optical comparator. It uses illumination light to provide a magnified image of a part to measure the dimensions of that part. This image can be compared to the original CAD drawing. The projector is highly efficient using smaller components.

X-ray fluorescence is a harmless analytical technique that allows us to determine the composition of materials. X-ray fluorescence uses short-wave X-rays or gamma rays to qualitatively and quantitatively analyze the composition of materials.

The Hofengfab team is committed to achieving impeccable standards and exceptional quality. If you receive an order that does not meet specifications, please contact us immediately at vivian@hofengfab.com.